Abstract

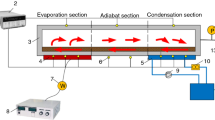

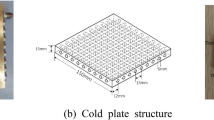

The vapour chambers are used in the electronic cooling applications to avoid the hot spots that result from the centralizing of the heat in the electronic components. The major effort of this study is to establish a standard vapour chamber design and evaluate its performance with different designs: with circular and square grooves of different sizes and with no grooves. Accordingly, two different sizes of the vapour chamber (100 × 100 × 3 mm3 and 90 × 90 × 3 mm3) were designed and their performance was evaluated experimentally. Moreover, five cold plates having different sizes of grooves (no groove, groove with 5 mm diameter, groove with 10 mm diameter, 30 × 30 mm2 square groove, and 60 × 60 mm2 square groove) were designed to test the effect of the groove size on the performance and the thermal resistances of the cold plate. The test results showed that the axial thermal resistances and the total thermal resistances decreased with increasing the groove size. In addition, it was investigated that the thermal resistances decrease with increasing the groove size, however, at a certain groove size (a circular groove with a diameter of 10 mm), the thermal resistance is the lowest. Therefore, the groove with 10 mm diameter was the optimum design that ensured the better enhancement in the performance of the vapour chamber.

Similar content being viewed by others

Abbreviations

- A:

-

Cross-sectional area of copper heater block (m2)

- k:

-

Thermal conductivity (W/m oC)

- L:

-

Length (m)

- \({L}_{i}\) :

-

The distance from the measuring thermocouple to the heater block (m)

- q:

-

Heat transfer rate (W)

- \({Q}_{W}\) :

-

Volume flow rate (litter/min)

- \({R}_{a}\) :

-

The axial thermal resistance (oC /W)

- \({R}_{s}\) :

-

The diffusion thermal resistance (oC /W)

- \({R}_{Total}\) :

-

Total thermal resistance (oC /W)

- \({R}_{vc}\) :

-

Vapor Chamber Thermal Resistance (oC /W)

- \({T}_{a}\) :

-

Ambient temperature (oC)

- \({T}_{avg}\) :

-

The average temperature (oC) of the four corners (\({T}_{vc, 1}, {T}_{vc, 2}, {T}_{vc, 3}, {T}_{vc, 4}, {T}_{vc, 5}\)) on the surface of the cold plate

- \({T}_{c}\) :

-

Center point temperature of below the vapour chamber(oC)

- \({T}_{vc}\) :

-

Center point temperature on the top surface of vapour chamber (oC)

- (\({T}_{w, avg}\)):

-

The average water temperature of the cold plate outlet

- \({T}_{w, in}\) :

-

Water inlet temperature (oC)

- \({T}_{w, out}\) :

-

Water outlet temperature (oC)

- a:

-

Ambient temperature

- avg:

-

Average

- c:

-

Centre point

- in:

-

Inlet

- out:

-

Outlet

- w:

-

Water

References

Tang Y, Yuan D, Lu L, Wang Z (2013) A multi-artery vapor chamber and its performance. Appl Therm Eng 60:15–23

Tsai MC, Kang SW, Paiva KV (2013) Experimental studies of thermal resistance in a vapor chamber heat spreader. Appl Therm Eng 56:38–44

Sun Z, Chen X, Qiu H (2014) Experimental investigation of a novel asymmetric heat spreader with nanostructure surfaces. Exp Thermal Fluid Sci 52:197–204

Chen YT, Miao JM, Ning DY (2009) Thermal performance of a vapor chamber heat pipe with diamond–copper composition wick structures, in: Proceedings of the 2009 4th International Microsystems, IEEE, Piscataway, NJ 340–343

Alizadeh M, Ganji DD (2021) Heat transfer characteristics and optimization of the efficiency and thermal resistance of a finned thermosyphon. Appl Therm Eng 183: 116136

Alizadeh M, Ganji DD (2020) Heat transfer characteristics of an external-fin- assisted two-phase closed thermosyphon: An experimental study. Heat Transfer 49(8):4304–4320

Alizadeh M, Ganji DD (2020) Multi-objective optimization of an externally finned two-phase closed thermosyphon using response surface methodology. Appl Therm Eng 171: 115008

Li C, Peterson GP, Wang Y (2006) Evaporation/boiling in thin capillary wicks – wick thickness effects. ASME J Heat Transf 128:1312–1319

Li C, Peterson GP (2006) Evaporation/boiling in thin capillary wicks-effects of volumetric porosity and mesh size. ASME J Heat Transf 128:1320–1328

Wang H, Garimella SV, Murthy JY (2007) Characteristics of an evaporating thin film in a microchannel. Int J Heat Mass Transf 50:3933–3942

Wang J, Catton I (2001) Enhanced evaporation heat transfer in triangular grooves covered with a thin fine porous layer. Appl Therm Eng 21:1721–1737

Mughal MP, Plumb OA (1996) An experimental study of boiling on a wicked surface. Int J Heat Mass Transf 39:771–777

Abhat A, Seban RA (1974) Boiling and evaporation from heat pipe wicks with water and acetone. J Heat Transfer 96:331–337

Nakayama W, Daikoku T, Kuwahara H, Nakajima T (1980) Dynamic model of enhanced boiling heat transfer in porous surfaces Part 1: Experimental investigation. J Heat Transfer 102:445–450

Iverson BD, Davis TW, Garimella SV, North MT (2007) Heat and mass transport in heat pipe wick structures. J Thermophys Heat Transfer 21:392–404

Liter SG, Kaviany M (2001) Pool-boiling CHF enhancement by modulated porous-layer coating: theory and experiment. Int J Heat Mass Transf 44:4287–4311

Ranjan R, Murthy JY, Garimella SV (2009) Analysis of the wicking and thin-film evaporation characteristics of wick microstructures. ASME J Heat Transf 131(10):101001

Weibel JA, Garimella SV, North MT (2010) Characterization of evaporation and boiling from sintered powder wicks fed by capillary action. Int J Heat Mass Transf 53(19–20):4204–4215

Ranjan R, Murthy JY, Garimella SV (2011) A microscale model for thin-film evaporation in capillary wick structures. Int J Heat Mass Transf 54(1–3):169–179

Ranjan R, Murthy JY, Garimella SV, Vadakkan U (2011) A numerical model for transport in flat heat pipes considering wick microstructure effects. Int J Heat Mass Transf 54(1–3):153–168

Ranjan R, Garimella SV, Murthy JY, Yazawa K (2011) Assessment of nanostructured capillary wicks for passive, two-phase heat transport. Nanoscale Microscale Thermophys Eng 15(3):179–194

Xiao R, Enright R, Wang EN (2010) Prediction and optimization of liquid propagation in micropillar arrays. Langmuir 26(19):15070–15075

Cui HH, Lim KM (2009) Pillar array microtraps with negative dielectrophoresis. Langmuir 25(6):3336

Zhou JJ, Noca F, Gharib M (2006) ‘‘Flow conveying and diagnosis with carbon nanotube arrays. Nanotechnology 17(19):4845–4853

Cai Q, Chen CL (2010) Design and test of carbon nanotube biwick structure for high-heat-flux phase change heat transfer. J Heat Transf 132(5):052403–1–052403–8 [26] A. Justin. V. S. Weibel, Y. J. Garimella, David H. Altman, Design of integrated nanostructured wicks for high-performance vapor chambers, IEEE Trans. Components Packaging Manuf Technol 1(6):859–867

Justin A, Weibel VS, Garimella YJ, Altman DH (2011) Design of integrated nanostructured wicks for high-performance vapor chambers, IEEE Trans. Components Packaging Manuf Technol 1(6):859–867

Wong S-C, Kuo-Chun Hsieh Wu, Jia-Da W-L (2010) A novel vapor chamber and its performance. Int J Heat Mass Transf 53:2377–2384

Amy Rachel Betz (2010) Jie Xu, Huihe Qiu, Daniel Attinger, Do surfaces with mixed hydrophilic and hydrophobic areas enhance pool boiling?, Appl. Phys Lett 97:141909-1-141909–3

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there is no conflict of interests regarding the publication of this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Mudhafar, M.H., Lu, Z. Experimental investigation of a novel heat spreader with smooth and multi-structure surfaces. Heat Mass Transfer 58, 1879–1896 (2022). https://doi.org/10.1007/s00231-022-03187-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-022-03187-1