Abstract

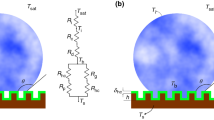

Condensation is a phase-change process in which vapor condenses to liquid at constant pressure. Condensation occurs in the forms of dropwise and filmwise. Investigations on hybrid hydrophobic-hydrophilic surfaces show their potential to improve condensation heat transfer characteristics in particular situations, comparing to complete dropwise condensation. In the present study, condensation on the microstructured hybrid tube has been examined, considering every thermal resistance on the heat flux. Two droplet morphologies, i.e., The Cassie state and the Wenzel state, have been considered. The influence of different parameters, including tube inclination angle, saturation vapor pressure, and dropwise/filmwise area ratio, has also been investigated. According to the results, droplet interaction with the surface significantly influences the heat transfer characteristics so that in most cases, the Wenzel state has a more considerable hybrid heat flux than the Cassie state. It has also been witnessed that the vertical tube has a higher heat flux comparing to tubes in other angles. A smaller liquid film thickness and a higher saturation vapor temperature were observed to have a higher heat flux. Finally, the increase in the dropwise region width decreases the droplet transition time from dropwise region to filmwise region and finally increases the hybrid heat flux.

Similar content being viewed by others

Abbreviations

- A 1 , A 2 , A 3 :

-

Parameters in model

- A :

-

Surface area (m2)

- B 1 , B 2 :

-

Parameters in model

- d :

-

Pillar diameter (m)

- g :

-

Gravitational acceleration (m s−2)

- h :

-

Pillar height (m)

- h fg :

-

Latent heat of evaporation (kJ kg−1)

- h i :

-

Interfacial heat transfer coefficient (W m−2 k−1)

- k :

-

Thermal conductivity (W m−1 K−1)

- l :

-

Center to center distance of the pillars (m)

- L :

-

Liquid layer thickness (m)

- Ma :

-

Marangoni number

- n :

-

Population density of small droplets (m−3)

- N :

-

Population density of large droplets (m−3)

- N s :

-

Nucleation site density on the surface (m−2)

- P :

-

Vapor pressure (Mpa)

- q :

-

Heat flux (W m−2)

- Q d :

-

Dropwise heat transfer rate (kW)

- r :

-

Droplet radius (m)

- r e :

-

Critical droplet radius (m)

- R :

-

Thermal resistance (k W–1)

- R g :

-

Specific gas constant (J kg−1 K−1)

- T :

-

Temperature (K)

- T c :

-

Critical temperature (K

- α:

-

Thermal diffusivity (m2 s−1)

- αc :

-

Condensation coefficient

- δ:

-

Layer thickness (m)

- ΔT:

-

Temperature difference/drop (K)

- Δθ:

-

Contact angle hysteresis (deg)

- θ:

-

Contact angle (deg)

- η:

-

Filmwise-dropwise area ratio

- ρ:

-

Density (kg m−3)

- σ:

-

Surface tension (N m−1)

- τ:

-

Sweeping period (s)

- ϕ:

-

Solid fraction

- μ:

-

Condensate viscosity (N s m−2)

- υ:

-

Water vapor specific volume (kg m−3)

- φ:

-

Peripheral angle (deg)

- γ:

-

Inclination angle (deg

- a:

-

Advancing

- c:

-

Droplet curvature

- coat:

-

Hydrophobic coating

- drop:

-

Droplet

- DWC:

-

Dropwise condensation

- FWC:

-

Filmwise condensation

- h:

-

Hybrid hydrophobic-hydrophilic

- int:

-

Interface

- Ma:

-

Marangoni convection

- max:

-

Maximum

- min:

-

Minimum

- n:

-

Small droplets

- N:

-

Large droplets

- p:

-

Pillar

- r:

-

Receding

- rough:

-

Roughness

- s:

-

Solid surface

- sat:

-

Saturation

- v:

-

Vapor

- w:

-

Water

- l:

-

Liquid

References

Wang C, Wang L, Zhao H, Du Z, Ding Z (2016) Effects of superheated steam on non-equilibrium condensation in ejector primary nozzle. Int J Refrig 67:214–226. https://doi.org/10.1016/j.ijrefrig.2016.02.022

Xie J, Xu JL, Xing F, Wang ZX, Liu H (2004) The phase separation concept condensation heat transfer in horizontal tubes for low-grade energy utilization. Energy 69:787–800

Xie J, Xu JL, Cheng Y, Xing F, He XT (2015) Condensation heat transfer of R245fa in tubes with and without lyophilic porous-membrane-tube insert. Int J Heat Mass Transf 88:261–275

Xie J, Xu JL, Liang C, She QT, Li MJ (2019) A comprehensive understanding of enhanced condensation heat transfer using phase separation concept. Energy 172:661–674

Griffith P (1985) Dropwise condensation. In: Rohsenow WP, Hartnett JP, Ganic EN (eds) Handbook of heat transfer fundamentals. McGraw-Hill, New York, p 13

Jakob M (1936) Heat transfer in evaporation and condensation. Mech Eng 58:729–739

Ruckenstien E, Metiu H (1965) On dropwise condensation on a solid surface. Chem Eng Sci 20(3):173–180

Le Fevre EJ, Rose JW (1966) A theory of heat transfer by dropwise condensation. In: Chemical Engineering Progress, Amer Inst Chemical Engineers, 345 E 47th St, New York, NY 10017, p 86

Tanaka HA (1975) Theoretical study of dropwise condensation. J Heat Transf 97(1):72–78

Burnside BM, Hadi HA (1999) Digital computer simulation of dropwise condensation from 21 equilibrium droplet to detectable size. Int J Heat Mass Transf 42(16):3137–3146

Law BM (2001) Wetting, adsorption and surface critical phenomena. Prog Surf Sci 66(6–8):159–216

Wenzel H (1957) Versuch ilber Tropf enkondensation Allg Warmetech 8:53

Cassie ABD, Baxter S (1944) Wettability of porous surfaces. Trans Faraday Soc 40:546–551

Miljkovic N, Enright R, Wang EN (2012) Effect of droplet morphology on growth dynamics and heat transfer during condensation on superhydrophobic nanostructured surfaces. ACS Nano 6:1776–1785

Kim H, Nam Y (2016) Condensation behaviors and resulting heat transfer performance of nano engineered copper surfaces. Int J Heat Mass Transf 93:286–292

Tianqing L, Chunfeng M, Xiangyu S, Songbai X (2007) Mechanism study on formation of initial condensate droplets. AIChE J 53(4):1050–1055

Kim S, Kim KJ (2011) Dropwise condensation modeling suitable for superhydrophobic surfaces. J Heat Transf 133(8):081502

Rausch MH, Leipertz A, Froba AP (2010) Dropwise condensation of steam on ion implanted titanium surfaces. Int J Heat Mass Transf 53(1–3):423–430

Vemuri S, Kim KJ (2006) An experimental and theoretical study on the concept of dropwise condensation. Int J Heat Mass Transf 49:649–657. https://doi.org/10.1016/j.ijheatmasstransfer.2005.08.016

Mei M, Yu B, Zou M, Luo L (2011) A numerical study on growth mechanism of dropwise condensation. Int J Heat Mass Transf 54:2004–2013

Glicksman LR, Hunt AW (1972) Numerical simulation of dropwise condensation. Int J Heat Mass Transf 15:2251–2269

Bansal GD, Khandekar S, Muralidhar K (2009) Measurement of heat transfer during dropwise condensation of water on polyethylene. Nanoscale Microscale Thermophys Eng 13(3):184–201

Das AK, Kilty HP, Marto PJ, Andeen GB, Kumar A (2000) The use of an organic self-assembled monolayer coating to promote dropwise condensation of steam on horizontal tubes. ASME J Heat Transf 122(2):278–286

Ma XH, Chen JB, Xu DQ, Lin JF, Ren CS, Long ZH (2002) Influence of processing conditions of polymer film on dropwise condensation heat transfer. Int J Heat Mass Transf 45(12):3405–3411

Pang GX, Dale JD, Kwok DY (2005) An integrated study of dropwise condensation heat transfer on self-assembled organic surfaces through Fourier transform infra-red spectroscopy and ellipsometry. Int J Heat Mass Transf 48(2):307–316

Yu BM, Cheng P (2002) Fractal models for the effective thermal conductivity of bidispersed porous media. J Thermophys Heat Transf 16(1):22–29

Maa JR (1978) Drop size distribution and heat flux of dropwise condensation. Chem Eng J 16:171–176

Hu HW, Tang GH (2014) Theoretical investigation of stable dropwise condensation heat transfer on a horizontal tube. Appl Therm Eng 62:671–679

Choi SU, Eastman J (1995) Enhancing thermal conductivity of fluids with nanoparticles. In: ASME International Mechanical Engineering Congress & Exposition, American Society of Mechanical Engineers, San Francisco

Masuda H, Ebata A, Teramae K (1993) Alteration of thermal conductivity and viscosity of liquid by dispersing ultra-fine particles Dispersion of Al2O3, SiO2 and TiO2 ultra-fine particles. Netsu Bussei 7(4):227–233

Keblinski P, Phillpot S, Choi S, Eastman J (2002) Mechanisms of heat flow in suspensions of nano-sized particles (nanofluids). Int J Heat Mass Transf 45(4):855–863

Cheng K, Kim S, Lee S, Kim KJ (2015) Internal dropwise condensation: Modeling and experimental framework for horizontal tube condensers. Int J Heat Mass Transf 83:99–108

Bahrami HRT, Saffari H (2017) Theoretical study of stable dropwise condensation on an inclined micro-nano-structured tube. Int J Refrig 75:141–154

Peng B, Ma X, Lan Z, Xu W, Wen R (2015) Experimental investigation on steam condensation heat transfer enhancement with vertically patterned hydrophobic–hydrophilic hybrid surfaces. Int J Heat Mass Transf 83:27–38

Yamauchi A, Kumagai S, Takeyama T (1986) Condensation heat transfer on various dropwise-filmwise coexisting surface. Heat Transf Jpn Res 15:50–64

Ma XH, Wang BX, Xu DQ et al (1998) Filmwise condensation heat transfer enhancement with dropwise and filmwise coexisting condensation surfaces. Chin J Chem Eng 2(6):98–102

Grooten MHM, van der Geld CWM (2011) Dropwise condensation from flowing air-steam mixtures: diffusion resistance assessed by controlled drainage. Int J Heat Mass Transf 54:4507–4517

Grooten MHM, van der Geld CWM (2012) Surface property effects on dropwise condensation heat transfer from flowing air-steam mixtures to promote drainage. Int J Therm Sci 54:220–229

Baghel V, Sikarwar BS, Muralidhar K (2019) Modeling of heat transfer through a liquid droplet. Heat Mass Transf 55(5):1371–1385

Phadnis A, Rykaczewski K (2017) The effect of Marangoni convection on heat transfer during dropwise condensation on hydrophobic and omniphobic surfaces. Int J Heat Mass Transf 115:148–158

Funding

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights

• An increase in contact angle decreases the hybrid heat flux.

• An increase in contact angle hysteresis decreases the hybrid heat flux.

• Vertical tube showed better heat transfer performance than horizontal one.

• In equal condition, Wenzel model has better heat transfer characteristics.

• Smaller pillar heights have the best heat transfer performance.

Rights and permissions

About this article

Cite this article

Aminian, E., Kamali, M., Vatanjoo, E. et al. Theoretical analysis on condensation heat transfer on microstructured hybrid hydrophobic-hydrophilic tube. Heat Mass Transfer 58, 1207–1221 (2022). https://doi.org/10.1007/s00231-021-03170-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-021-03170-2