Abstract

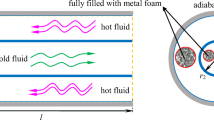

A parametric study is proposed in this paper to examine heat dissipation rate and entropy generation of a forced convection in a horizontal pipe which is filled with high porous metallic foams. The study quantifies the effect of thermal conductivity and pore density on entropy generation when the pipe is fully filled with copper, aluminium and nickel metallic foams of 0.6 m length in the fluid flow direction. To predict fluid flow and heat transfer features through these metallic foams the Darcy-extended Forchheimer (DEF) flow and the local thermal non-equilibrium (LTNE) models are employed. The characteristics of laminar, transition and turbulent in the non-foam region of the pipe are captured by considering the appropriate flow models. To affirm the methodology adopted in this work, the results of the present numerical solutions are validated with the available experimental results reported in the literature. Colburn j factor and thermal performance factor are the important factors that decide the performance and efficiency of any heat exchange device. Hence, these parameters are critically evaluated and are observed to increase with increasing pore densities of the metal foams and decrease with increasing flow rates of the fluid. Furthermore, the numerical analysis is extended to obtain the results of wall temperature, Nusselt number, heat transfer enhancement ratio, frictional irreversibility and Bejan number.

Similar content being viewed by others

Abbreviations

- A:

-

Area of the pipe (m2)

- u:

-

Velocity of fluid (m/s)

- L:

-

Length of the pipe (m)

- Lf :

-

Length of the metal foam (m)

- T:

-

Temperature (°C) or (°K)

- asf :

-

Interfacial surface area (m−1)

- C:

-

Form drag coefficient (m−1)

- Cp :

-

Specific heat of fluid (J/kg K)

- dp :

-

Pore diameter (m)

- df :

-

Fiber diameter (m)

- f:

-

Friction coefficient

- h:

-

Heat transfer coefficient (W/m2°C)

- hsf :

-

Interfacial heat transfer coefficient (W/m2°C)

- K:

-

Permeability (m2)

- Pr:

-

Prandtl number

- Re:

-

Reynolds number based on hydraulic diameter

- q”:

-

heat flux (W/m2)

- \( {\operatorname{Re}}_{{\mathrm{d}}_{\mathrm{f}}} \) :

-

Reynolds number based on fiber diameter

- D:

-

Diameter of the pipe (m)

- Dh :

-

Hydraulic diameter of the pipe (m)

- λ:

-

Thermal conductivity (W/m°C)

- P:

-

Perimeter of the pipe (m)

- \( \overline{\mathrm{Nu}} \) :

-

Average Nusselt number filled foam pipe

- \( \overline{{\mathrm{Nu}}_{\Phi}} \) :

-

Average Nusselt number of empty pipe

- NuER :

-

Heat transfer enhancement ratio

- ɛ:

-

Porosity

- λ:

-

Thermal conductivity (W/m°C)

- μ:

-

Dynamic viscosity of the fluid (Ns/m2)

- ν:

-

Kinematic viscosity (m2/s)

- ρ:

-

Density of the fluid (kg/m3)

- i:

-

Each data points/Local data points

- ER :

-

Enhancement ratio

- w:

-

Wall

- f:

-

Fluid

- eff:

-

Effective

- s:

-

Solid

- se:

-

Solid effective

- fe:

-

Fluid effective

References

Nazari M, Ashouri M, Kayhani MH, Tamayol A (2015) Experimental study of convective heat transfer of a nanofluid through a pipe filled with metal foam. Int J Therm Sci 88:33–39. https://doi.org/10.1016/j.ijthermalsci.2014.08.013

Xu HJ, Qu ZG, Lu TJ et al (2011) Thermal modeling of forced convection in a parallel-plate channel partially filled with metallic foams. J Heat Transf 133:092603. https://doi.org/10.1115/1.4004209

Xu HJ, Gong L, Zhao CY et al (2015) Analytical considerations of local thermal non-equilibrium conditions for thermal transport in metal foams. Int J Therm Sci 95:73–87. https://doi.org/10.1016/j.ijthermalsci.2015.04.007

Lin W, Xie G, Yuan J, Sundén B (2016) Comparison and analysis of heat transfer in aluminum foam using local thermal equilibrium or nonequilibrium model. Int J Heat Transf Eng 37:3-4, 314-322: 7632. https://doi.org/10.1080/01457632.2015.1052682

Lu W, Zhang T, Yang M (2016) Analytical solution of forced convective heat transfer in parallel-plate channel partially filled with metallic foams. Int J Heat Mass Transf 100:718–727. https://doi.org/10.1016/j.ijheatmasstransfer.2016.04.047

Celik H, Mobedi M, Oronzio Manca UO (2014) A pore scale analysis for determination of interfacial convective heat transfer coefficient for thin periodic porous media under mixed convection Int J Numer Methods Heat Fluid Flow. https://doi.org/10.1108/HFF-01-2017-0036

Kotresha B, Gnanasekaran N (2019) Effect of thickness and thermal conductivity of metal foams filled in a vertical channel – a numerical study. Int J Numer Methods Heat Fluid Flow 29:184–203. https://doi.org/10.1108/HFF-11-2017-0465

Gangapatnam P, Kurian R (2018) Numerical simulation of heat transfer in metal foams. Heat Mass Transf:553–562. https://doi.org/10.1007/s00231-017-2149-6

Li Z, Xia X, Li X, Sun C (2018) Discrete vs. continuum-scale simulation of coupled radiation and convection inside rectangular channel filled with metal foam. Int J Therm Sci 132:219–233. https://doi.org/10.1016/j.ijthermalsci.2018.06.010

Baragh S, Shokouhmand H, Ajarostaghi SSM, Nikian M (2018) An experimental investigation on forced convection heat transfer of single-phase flow in a channel with different arrangements of porous media. Int J Therm Sci 134:370–379. https://doi.org/10.1016/j.ijthermalsci.2018.04.030

Sheikhnejad Y, Hosseini R, Saffar Avval M (2017) Experimental study on heat transfer enhancement of laminar ferrofluid flow in horizontal tube partially filled porous media under fixed parallel magnet bars. J Magn Magn Mater 424:16–25. https://doi.org/10.1016/j.jmmm.2016.09.098

Bağcı Ö, Dukhan N (2018) Impact of pore density on oscillating liquid flow in metal foam. Exp Thermal Fluid Sci 97:246–253. https://doi.org/10.1016/j.expthermflusci.2018.04.020

Bamorovat Abadi G, Kim KC (2017) Experimental heat transfer and pressure drop in a metal-foam-filled tube heat exchanger. Exp Thermal Fluid Sci 82:42–49. https://doi.org/10.1016/j.expthermflusci.2016.10.031

Li Y, Wang S, Zhao Y (2018) Experimental study on heat transfer enhancement of gas tube partially filled with metal foam. Exp Thermal Fluid Sci 97:408–416. https://doi.org/10.1016/j.expthermflusci.2018.05.002

Nakayama CYKAA (2011) A local thermal non-equilibrium analysis of fully developed forced convective flow in a tube filled with a porous medium. https://doi.org/10.1007/s11242-011-9766-1

Yang C, Kuwahara F, Liu W, Nakayama A (2011) Thermal non-equilibrium forced convective flow in an annulus filled with a porous medium. The Open Transport Phenomena Journal 3:31–39

Lu X, Zhao Y (2019) International journal of heat and fluid flow effect of flow regime on convective heat transfer in porous copper manufactured by lost carbonate sintering. Int J Heat Fluid Flow 80:108482. https://doi.org/10.1016/j.ijheatfluidflow.2019.108482

Barlettta A, Magyari E, Pop I, Storesletten L (2008) Mixed convection with viscous dissipation in an inclined porous channel with isoflux impermeable walls. Int J Heat Mass Transf 44:979–988. https://doi.org/10.1007/s00231-007-0324-x

Alomar OR (2019) Numerical investigation of two-phase flow in a horizontal porous evaporator with localised heating using non-Darcian flow and two equations model. Heat Mass Transf. https://doi.org/10.1007/s00231-019-02784-x

Tio K, Liu CY, Toh KC (2000) Thermal analysis of micro heat pipes using a porous-medium model. Heat Mass Transf 36:21–28

Edrisi S, Kasiri N, Maryam B (2017) A new approach to modeling the effective thermal conductivity of ceramics porous media using a generalized self - consistent method. Heat Mass Transf 53:321–330. https://doi.org/10.1007/s00231-016-1821-6

Jouybari NF, Maerefat M, Nimavari ME (2016) A pore scale study on turbulent combustion in porous media. Heat Mass Transf:269–280. https://doi.org/10.1007/s00231-015-1547-x

Ozdemir M, Ozguc AF (1997) Forced convective heat transfer in porous medium of wire screen meshes. Heat Mass Transf 33:129–136

Xu H, Zhao C, Vafai K (2017) Analytical study of flow and heat transfer in an annular porous medium subject to asymmetrical heat fluxes. Heat Mass Transf 53:2663–2676. https://doi.org/10.1007/s00231-017-2011-x

Bejan A (1979) Astudy of entropy generation in fundamental convective heat transfer. J Heat Transfer 101:718–725

Bejan A (1980) Second law analysis in heat transfer. Enegy 5(8):720–732

Bejan A (1982) Second law analysis in heat transfer and thermal design. Adv Heat Transfer 15:1–58

Bejan A (1996) Entropy generation minimization. CRC Press, New York

Nield DA (2006) A enote on a brinkman – brinkman forced convection problem, pp 185–188. https://doi.org/10.1007/s11242-005-2810-2

Nield DA (2007) The modeling of viscous dissipation in a saturated porous medium 129:1459–1463. https://doi.org/10.1115/1.2755069

Kurtbas I, Celik N, Dincer I (2010) Exergy transfer in a porous rectangular channel exergy transfer in a porous rectangular channel. Energy 35:451–460. https://doi.org/10.1016/j.energy.2009.10.011

Prommas R, Rattanadecho P, Cholaseuk D (2010) Energy and exergy analyses in drying process of porous media using hot air. Int Commun Heat Mass Transf 37:372–378. https://doi.org/10.1016/j.icheatmasstransfer.2009.12.006

Torabi M, Zhang K, Yang G et al (2015) Heat transfer and entropy generation analyses in a channel partially fi lled with porous media using local thermal non-equilibrium model. Energy 82:922–938. https://doi.org/10.1016/j.energy.2015.01.102

Torabi M, Dickson C, Karimi N (2016) Theoretical investigation of entropy generation and heat transfer by forced convection of copper – water nano fluid in a porous channel local thermal non-equilibrium and partial filling effects. Powder Technol 301:234–254. https://doi.org/10.1016/j.powtec.2016.06.017

Hunt G, Karimi N, Torabi M (2018) Two-dimensional analytical investigation of coupled heat and mass transfer and entropy generation in a porous , catalytic microreactor. Int J Heat Mass Transf 119:372–391. https://doi.org/10.1016/j.ijheatmasstransfer.2017.11.118

Hooman K, Haji-sheikh A (2007) Analysis of heat transfer and entropy generation for a thermally developing brinkman – brinkman forced convection problem in a rectangular duct with iso-flux walls. 50:4180–4194. https://doi.org/10.1016/j.ijheatmasstransfer.2007.02.036

Hooman K, Gurgenci H, Merrikh AA (2007) Heat transfer and entropy generation optimization of forced convection in porous-saturated ducts of rectangular cross-section 50:2051–2059. https://doi.org/10.1016/j.ijheatmasstransfer.2006.11.015

Srinivasacharya D, Bindu KH (2017) Entropy generation of micropolar fluid flow in an inclined porous pipe with convective boundary conditions. Sādhanā 42:729–740. https://doi.org/10.1007/s12046-017-0639-3

Bekir SZS, Yilbas S (2008) Entropy generation in flow field subjected to a porous block in a vertical channel. 179–197. https://doi.org/10.1007/s11242-007-9143-2

Tayari A, Ben A, Magherbi M (2015) Second law analysis in mixed convection through an inclined porous channel. Int J Thermophys 36:2881–2896. https://doi.org/10.1007/s10765-015-1925-0

Nazari M, Vahid DJ, Saray RK, Mahmoud Y (2017) Experimental investigation of heat transfer and second law analysis in a pebble bed channel with internal heat generation. Int J Heat Mass Transf 114:688–702. https://doi.org/10.1016/j.ijheatmasstransfer.2017.06.079

Oztop HF, Al-salem K (2012) A review on entropy generation in natural and mixed convection heat transfer for energy systems. Renew Sust Energ Rev 16:911–920. https://doi.org/10.1016/j.rser.2011.09.012

Ratts EB (2004) Entropy generation minimization of fully developed internal flow with constant heat flux 126:656–659. https://doi.org/10.1115/1.1777585

Khaboshan HN, Nazif HR (2019) Entropy generation analysis of convective turbulent flow in alternating elliptical axis tubes with different angles between pitches ; a numerical investigation. Heat Mass transf 55:2857–2872. https://doi.org/10.1007/s00231-019-02615-z

Pavel BI, Mohamad AA (2004) An experimental and numerical study on heat transfer enhancement for gas heat exchangers fitted with porous media 47:4939–4952. https://doi.org/10.1016/j.ijheatmasstransfer.2004.06.014

Sunden B (2012) Introduction to heat transfer. WIT Press, Ashurst, UK

Mahmoudi Y, Karimi N (2014) International journal of heat and mass transfer numericalinvestigation of heat transfer enhancement in a pipe partially filled with a porous material under local thermal non-equilibrium condition. Int J Heat Mass Transf 68:161–173. https://doi.org/10.1016/j.ijheatmasstransfer.2013.09.020

ANSYS Fluent (2017) ANSYSV R [ANSYS Fluent], 15.0, Help System, User’s Guide/Theory Guide. ANSYS, Inc., Canonsburg, PA, http://www.ansys.com/Products/Fluids/ANSYS-Fluent

Walters DK (2019) A Three-Equation Eddy-Viscosity Model for Reynolds-Averaged Navier – Stokes Simulations of 130:. https://doi.org/10.1115/1.2979230

Kotresha B, Gnanasekaran N (2019) Numerical simulations of fluid flow and heat transfer through aluminum and copper metal foam heat exchanger – a comparative study numerical simulations of fluid flow and heat transfer through aluminum. Heat Transf Eng 0:1–13. https://doi.org/10.1080/01457632.2018.1546969

Huang ZF, Nakayama A, Yang K (2010) International journal of heat and mass transfer enhancing heat transfer in the core flow by using porous medium insert in a tube. Int J HeatMassTransf 53:1164–1174. https://doi.org/10.1016/j.ijheatmasstransfer.2009.10.038

Calmidi VV, Mahajan RL (2002) Forced convection in high porosity metal foams. J Heat Transf 122:557. https://doi.org/10.1115/1.128779

Zukauskas AA (1987) Convective heat transfer in cross-flow. In: Kakac S, Shah RK, Aung W (eds) Handbook of single-phase convective heat transfer. Wiley, New York

Singh PK, Anoop KB, Sundararajan T, Das SK (2010) International journal of heat and mass transfer entropy generation due to flow and heat transfer in nanofluids. Int J Heat Mass Transf 53:4757–4767. https://doi.org/10.1016/j.ijheatmasstransfer.2010.06.016

Ebrahimi A, Rikhtegar F, Sabaghan A, Roohi E (2016) Heat transfer and entropy generation in a microchannel with longitudinal vortex generators using nano fluids. Energy 101:190–201. https://doi.org/10.1016/j.energy.2016.01.102

Garrity PT, Klausner JF (2015) Performance of aluminum and carbon foams for air side heat transfer augmentation 132:1–9. https://doi.org/10.1115/1.4002172

Shokouhmand H, Jam F, Salimpour MR (2011) The effect of porous insert position on the enhanced heat transfer in partially filled channels. Int Commun Heat Mass Transf 38:1162–1167. https://doi.org/10.1016/j.icheatmasstransfer.2011.04.027

Boomsma K, Poulikakos D, Zwick F (2003) Metal foams as compact high performance heat exchanger. Mech Mater 35(12):1161–1176

Manglik R M (2003) Heat transfer enhancement heat transfer handbook. Wiley Hoboken NJ, pp 1029–1130

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Jadhav, P.H., Nagarajan, G. & Perumal, D.A. Conjugate heat transfer study comprising the effect of thermal conductivity and irreversibility in a pipe filled with metallic foams. Heat Mass Transfer 57, 911–930 (2021). https://doi.org/10.1007/s00231-020-03000-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-020-03000-x