Abstract

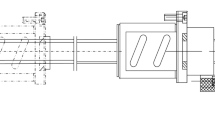

Journal bearings are used in industrial equipment at high rotational speed. Normal and also fault operations of bearing increase the temperature of the bearing. Estimation of heat flux on the inner surface of the bearing and prediction of temperature of the bearing can prevent the damage to the bearing. In this research, these quantities are estimated in normal operation by an inverse method. The sequential function specification method is applied and the best number of temperature sensors and their positions are obtained. The temperature sensors are embedded in the bearing. The results show that the accuracy of heat flux estimation has a district relation with the number and the position of the sensors and also with the measurement frequency.

Similar content being viewed by others

Abbreviations

- L:

-

Length of bearing

- C r :

-

Radial clearance

- C :

-

Specific heat

- e :

-

Eccentricity

- e bias :

-

Bias error

- e rms :

-

Root mean square error

- e var :

-

Variance error

- H 1 :

-

Ambient heat transfer coefficient

- H 2 :

-

Oil heat transfer coefficient

- k :

-

Thermal conductivity

- m :

-

Time index

- N m :

-

Number of time steps

- N s :

-

Number of sensors

- N p :

-

Number of segments of unknown heat flux

- O B :

-

Center of the journal bearing

- O S :

-

Center of the shaft

- P :

-

Pressure

- q :

-

Heat flux vector

- qin :

-

Inlet heat flux

- R :

-

Radial coordinates

- \({R}_{B_i}\) :

-

Inner radius of the journal bearing

- \({R}_{B_O}\) :

-

Outer radius of the journal bearing

- R S :

-

Shaft radius

- r :

-

Number of future time steps

- Sh :

-

Heat source

- T :

-

Vector of calculated temperatures

- \(\hat{\boldsymbol{T}}\) :

-

Calculated temperature

- T air :

-

Ambient temperature

- T s :

-

Supply oil temperature

- T 0 :

-

Initial temperature

- t :

-

Time

- t + :

-

Dimensionless time

- u r :

-

The velocity component in r

- u θ :

-

The velocity component in θ

- X :

-

Sensitivity coefficient matrix

- X + :

-

Dimensionless sensitivity coefficient matrix

- Y :

-

Measured temperature

- Z + :

-

Kind of dimensionless sensitivity coefficient matrix

- ∆t :

-

Time step

- θ:

-

Tangential coordinate

- μ:

-

Dynamic viscosity as a function of temperature

- μ0 :

-

Dynamic viscosity at 303 K

- ρ :

-

Density

- σ:

-

Standard deviation of fluctuation

- ψ :

-

The dissipation function

- φ :

-

Attitude angle

- ω :

-

Rotational speed

- α :

-

Coefficient of thermal expansion

- i:

-

Time index

- j:

-

Sensor index

- mean:

-

Measured

- opt:

-

Optimum

- S:

-

Shaft

- B:

-

Bearing

- f:

-

Fluid

References

Budynas RG, Nisbett JK (2010) Shigley's mechanical engineering design. McGraw-Hill Education, New York

Childs THC (2004) Mechanical design. Butterworth-Heinemann, Burlington

Choe KY, On SY, Song SA, Lim JW, You JI, Kim SS (2015) Study of the endurance performance of composite journal bearings under the oil cut situation. Compos Struct 134:772–781. https://doi.org/10.1016/j.compstruct.2015.08.122

Vats P, Sharma BC, Sharma S (2014) Heat transfer through journal bearing: a case study. Int J Res Eng Tech. 3:216-221. https://doi.org/10.15623/ijret.2014.0310033

Boyce MP (2006) Gas turbine engineering handbook. Gulf Professional Publishing, Burlington

Ludema KC (1996) Friction, wear, lubrication. CRC Press, Florida

Stachowiak GW, Batchelor AW (2013) Engineering tribology. Butterworth-Heinemann, Burlington

Someya T, Mitsui J, Esaki J, Saito S, Kanemitsu Y, Iwatsubo T, Tanaka M, Hisa S, Fujikawa T (2013) Journal-bearing databook. Springer-Verlag, Berlin

Frene J, Nicolas D, Degueurce B, Berthe D, Godet M (1997) Hydrodynamic lubrication, bearings and trust bearings. Elsevier Science & Technology, Oxford

Kucinschi B-R, Fillon M, Frene J, Pascovici MD (2000) A transient thermoelastohydrodynamic study of steadily loaded plain journal bearings using finite element method analysis. J Tribol 122:219–226. https://doi.org/10.1115/1.555346

Khonsari MS, Wang SH (1992) Notes on transient THD effects in a lubricating film. Tribol Trans 35:177–183. https://doi.org/10.1080/10402009208982106

Yan-li FU, Xi-Zhi MA, Jun ZHU (2003) A transient thermohydrodynamics study of plain journal bearings using Newton–Raphson method analysis. Chin J Aeronaut 16:233–240. https://doi.org/10.1016/S1000-9361(11)60190-8

Kucinschi B, Fillon M (1999) An experimental study of transient thermal effects in a plain journal bearing. J Tribol 121:327–332. https://doi.org/10.1115/1.2833940

Boncompain R, Fillon M, Frene J (1986) Analysis of thermal effects in hydrodynamic bearings. J Tribol 108:219–224. https://doi.org/10.1115/1.3261166

Ozisik MN, Orlando HRB (2000) Inverse heat transfer: fundamentals and applications. Taylor & Francis, New York

Sawaf B, Ozisik MN, Jarny Y (1995) An inverse analysis to estimate linearly temperature dependent thermal conductivity components and heat capacity of an orthotropic medium. Int J Heat Mass Transf 38:3005–3010. https://doi.org/10.1016/0017-9310(95)00044-A

Zhou J, Zhang Y, Chen JK, Feng ZC (2012) Three-dimensional inverse heat transfer in a composite target subject to high-energy laser irradiation. J Heat Transf 134:111201. https://doi.org/10.1115/1.4006107

Lee H-L, Chang W-J, Chen W-L, Yang Y-C (2012) Inverse heat transfer analysis of a functionally graded fin to estimate time-dependent base heat flux and temperature distributions. Energy Convers Manag 57:1–7. https://doi.org/10.1016/j.enconman.2011.12.002

Chen W-L, Yang Y-C (2008) Estimation of the transient heat transfer rate at the boundary of an electronic chip packaging. Numer Heat Transf Part A: Appl 54:945–961. https://doi.org/10.1080/10407780802473574

Zhou J, Zhang Y, Chen JK, Feng ZC (2009) Inverse heat conduction in a finite slab with measured Back surface temperature and heat Flux. 47th AIAA Aerospace sciences meeting including the new horizons forum and aerospace exposition. https://doi.org/10.2514/1.40549

Lee H-L, Yang Y-C, Chang W-J, Wu T-S (2009) Estimation of heat flux and thermal stresses in multilayer gun barrel with thermal contact resistance. Appl Math Comput 209:211–221. https://doi.org/10.1016/j.amc.2008.12.038

Yang Y-C, Chu S-S, Chang W-J, Wu T-S (2010) Estimation of heat flux and temperature distributions in a composite strip and homogeneous foundation. Int Commun Heat Mass Transf 37:495–500. https://doi.org/10.1016/j.icheatmasstransfer.2010.02.005

Beck JV, Blackwell B, Clair CRS (1985) Inverse heat conduction: ill-posed problems. John Wiley & Sons, New York

Kim H-J, Kim N-K, Kwak J-S (2006) Heat flux distribution model by sequential algorithm of inverse heat transfer for determining workpiece temperature in creep feed grinding. Int J Mach Tools Manuf 46:2086–2093. https://doi.org/10.1016/j.ijmachtools.2005.12.007

Hon YC, Wei T (2004) A fundamental solution method for inverse heat conduction problem. Eng Anal Bound Elem 28:489–495. https://doi.org/10.1016/S0955-7997(03)00102-4

Vikhrenko V (2011) Heat conduction. IntechOpen, London

Deng S, Hwang Y (2007) Solution of inverse heat conduction problems using Kalman filter-enhanced Bayesian back propagation neural network data fusion. Int J Heat Mass Transf 50:2089–2100. https://doi.org/10.1016/j.ijheatmasstransfer.2006.11.019

Sagheby SH, Kowsary F (2009) Experimental design and methodology for estimation of local heat transfer coefficient in jet impingement using transient inverse heat conduction problem. Exp Heat Transf 22:300–315. https://doi.org/10.1080/08916150903099314

Najafi H, Woodbury KA, Beck JV (2015) Real time solution for inverse heat conduction problems in a two-dimensional plate with multiple heat fluxes at the surface. Int J Heat Mass Transf 91:1148–1156. https://doi.org/10.1016/j.ijheatmasstransfer.2015.08.020

Najafi H, Woodbury KA, Beck JV (2015) A filter based solution for inverse heat conduction problems in multi-layer mediums. Int J Heat Mass Transf 83:710–720. https://doi.org/10.1016/j.ijheatmasstransfer.2014.12.055

Farahani SD, Kowsary F (2012) Estimation local convective boiling heat transfer coefficient in mini channel. Int Commun Heat Mass Transf 39:304–310. https://doi.org/10.1016/j.icheatmasstransfer.2011.11.007

Farahani SD, Kowsary F, Jamali J (2014) Direct estimation of local convective boiling heat transfer coefficient in mini-channel by using conjugated gradient method with adjoint equation. Int Commun Heat Mass Transf 55:1–7. https://doi.org/10.1016/j.icheatmasstransfer.2014.03.004

Monmousseau P, Fillon M, Frene J (1997) Transient thermoelastohydrodynamic study of tilting-pad journal bearings—comparison between experimental data and theoretical results. J Tribol 119:401–407. https://doi.org/10.1115/97-GT-400

Ettles CMM, Heshmat H, Brockwell KR (1989) Elapsed time for the decay of thermal transients in fluid film bearing assemblies. Tribol Ser 14:229–235. https://doi.org/10.1016/S0167-8922(08)70198-6

Martin FA (1998) Oil flow in plain steadily loaded journal bearings: realistic predictions using rapid techniques. Proc IME J J Eng Tribol 212:413–425. https://doi.org/10.1243/1350650981542227

Kadam KR, Banwait SS, Laroiya SC (2014) The influence of modified viscosity-temperature equation on Thermohydrodynamic analysis of plain journal bearing. Am J Mech Eng 2:169–177. https://doi.org/10.12691/ajme-2-6-4

Wang X-L, Zhu K-Q, Wen S-Z (2001) Thermohydrodynamic analysis of journal bearings lubricated with couple stress fluids. Tribol Int 34:335–343. https://doi.org/10.1016/S0301-679X(01)00022-6

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Alibeyki, D., Mehryar, R. Heat flux estimation in journal bearings using inverse heat transfer method. Heat Mass Transfer 57, 605–615 (2021). https://doi.org/10.1007/s00231-020-02959-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-020-02959-x