Abstract

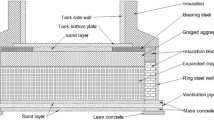

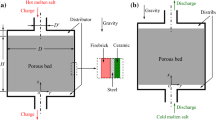

The two-tank thermal energy storage system with a mixture of sodium nitrate and potassium nitrate is one of the most common ways in concentrated solar power plants. However, the unreasonable thermal performance of tank foundations such as excessive heat loss and overheating of concrete slab could result in local molten salt solidification and foundation settlement. This work proposes a novel foundation configuration with road base, light expanded clay aggregate, thermal clay blocks and fire bricks as insulation materials. The temperature distribution and heat loss of the tank foundations are studied at different scales through experimental and numerical methods. A laboratory foundation is set up to prove the feasibility of foundation materials, which is used in the thermal energy storage system of the 1 MWth pilot plant. According to the results, the pilot foundation has a reasonable temperature distribution. Moreover, the foundation configuration and materials are applied to an industrial molten salt tank foundation. The maximum temperature of external surface of the foundation drops from 162.6 °C to 37.3 °C, the maximum temperature of concrete slab decreases from 96.1 °C to 43.2 °C, and the heat loss of foundation reduces by 39.8%. The results indicate that the foundation with the proposed configuration and materials could enhance the thermal performance of the tank foundation and decrease the heat loss through the tank foundation. The proposed foundation is of great significance for guiding the construction of the thermal storage system of commercial concentrated solar power plants.

Similar content being viewed by others

Abbreviations

- a ms :

-

molten salt absorptivity

- \( {\dot{g}}_{us} \) :

-

irradiation on molten salt upper surface (W/m2)

- \( {\dot{m}}_{in, ms} \) :

-

mass flow rate entering the control volume (kg/s)

- \( {\dot{m}}_{out, ms} \) :

-

mass flow rate leaving the control volume (kg/s)

- \( \dot{Q} \) :

-

total heat loss of molten salt (W)

- \( {\dot{Q}}_b \) :

-

heat loss through tank bottom (W)

- \( {\dot{Q}}_{\mathrm{d}w} \) :

-

heat loss through dry walls (W)

- \( {\dot{Q}}_{so} \) :

-

heat loss to soil (W)

- \( {\dot{Q}}_{us} \) :

-

heat loss through molten salt upper surface (W)

- \( {\dot{Q}}_{ven} \) :

-

heat loss to ventilating system (W)

- \( {\dot{Q}}_{ww} \) :

-

heat loss through wet vertical walls (W)

- S b :

-

tank bottom area (m2)

- S us :

-

area of molten salt upper surface (m2)

- S ww :

-

wet vertical wall area (m2)

- T b :

-

tank bottom temperature (°C)

- T amb :

-

ambient temperature (°C)

- T gu :

-

gas ullage temperature (°C)

- T i :

-

insulation temperature (°C)

- T ms :

-

molten salt temperature (°C)

- T sky :

-

sky temperature (°C)

- T so :

-

soil temperature (°C)

- T ts :

-

tank shell temperature (°C)

- T us :

-

upper surface molten salt temperature (°C)

- T ww :

-

wet vertical wall temperature (°C)

- α b :

-

superficial heat transfer coefficient at tank bottom (W/(m2·K))

- α ext :

-

superficial heat transfer coefficient at external surface (W/(m2·K))

- α us :

-

superficial heat transfer coefficient at molten salt upper surface (W/(m2·K))

- α ww :

-

superficial heat transfer coefficient at wet vertical wall (W/(m2·K))

- ε ms :

-

molten salt thermal emissivity.

- λ i :

-

thermal conductivity of insulation (W/(m·K))

- λ ts :

-

thermal conductivity of tank shell (W/(m·K))

- σ :

-

Stefan-Boltzmann constant (W/(m2·K4))

References

Pacheco JE, Gilbert R (1999). Overview of recent results of the solar two test and evaluations program. In: 1999 ASME International Solar Energy Conference

Prieto C, Osuna R, Fernández AI, Cabeza LF (2016) Thermal storage in a MW scale. Molten salt solar thermal pilot facility: plant description and commissioning experiences. Renew Energy 99:852–866. https://doi.org/10.1016/j.renene.2016.07.053

Prieto C, Osuna R, Fernández AI, Cabeza LF (2016) Molten salt facilities, lessons learnt at pilot plant scale to guarantee commercial plants; heat losses evaluation and correction. Renew Energy 94:175–185. https://doi.org/10.1016/j.renene.2016.03.039

Aringhoff R, Geyer M, Herrmann U, et al (2002). AndaSol-50 MW solar plants with 9 hour storage for southern Spain. In: 11th SolarPACES international symposium on concentrated solar power and chemical energy technologies. pp 37–42

Relloso S, Delgado E (2009). Experience with molten salt thermal storage in a commercial parabolic trough plant. Andasol-1 commissioning and operation. In: 15th SolarPACES conference. pp 1–9

Kelly B, Kearney D (2006). Thermal storage commercial plant design study for a 2-tank indirect molten salt system.National Renewable Energy Laboratory

Gabbrielli R, Zamparelli C (2009) Optimal design of a molten salt thermal storage tank for parabolic trough solar power plants. J Sol Energy Eng 131:041001–041010. https://doi.org/10.1115/1.3197585

Herrmann U, Kelly B, Price H (2004) Two-tank molten salt storage for parabolic trough solar power plants. Energy 29:883–893. https://doi.org/10.1016/S0360-5442(03)00193-2

Schulte-Fischedick J, Tamme R, Herrmann U (2009). CFD analysis of the cool down behaviour of molten salt thermal storage systems. In: 2nd International Conference on Energy Sustainability. pp 515–524

Rodríguez I, Pérez-Segarra CD, Lehmkuhl O, Oliva A (2013) Modular object-oriented methodology for the resolution of molten salt storage tanks for CSP plants. Appl Energy 109:402–414. https://doi.org/10.1016/j.apenergy.2012.11.008

Torras S, Pérez-Segarra CD, Rodríguez I et al (2015) Parametric study of two-tank TES systems for CSP plants. Energy Procedia 69:1049–1058. https://doi.org/10.1016/j.egypro.2015.03.206

Zaversky F, García-Barberena J, Sánchez M, Astrain D (2013) Transient molten salt two-tank thermal storage modeling for CSP performance simulations. Sol Energy 93:294–311. https://doi.org/10.1016/j.solener.2013.02.034

Suárez C, Pino FJ, Rosa F, Guerra J (2015) Heat loss from thermal energy storage ventilated tank foundations. Sol Energy 122:783–794. https://doi.org/10.1016/j.solener.2015.09.045

Suárez C, Iranzo A, Pino FJ, Guerra J (2015) Transient analysis of the cooling process of molten salt thermal storage tanks due to standby heat loss. Appl Energy 142:56–65. https://doi.org/10.1016/j.apenergy.2014.12.082

Yang Z, Garimella SV (2010) Molten-salt thermal energy storage in thermoclines under different environmental boundary conditions. Appl Energy 87:3322–3329. https://doi.org/10.1016/j.apenergy.2010.04.024

Xu C, Wang Z, He Y et al (2012) Sensitivity analysis of the numerical study on the thermal performance of a packed-bed molten salt thermocline thermal storage system. Appl Energy 92:65–75. https://doi.org/10.1016/j.apenergy.2011.11.002

Yin H, Ding J, Jiang R, Yang X (2017) Thermocline characteristics of molten-salt thermal energy storage in porous packed-bed tank. Appl Therm Eng 110:855–863. https://doi.org/10.1016/j.applthermaleng.2016.08.214

Chang Z, Li X, Xu C et al (2016) The effect of the physical boundary conditions on the thermal performance of molten salt thermocline tank. Renew Energy 96:190–202. https://doi.org/10.1016/j.renene.2016.04.043

Prieto C, Miró L, Peiró G et al (2016) Temperature distribution and heat losses in molten salts tanks for CSP plants. Sol Energy 135:518–526. https://doi.org/10.1016/j.solener.2016.06.030

Yang X, Yang X, Qin FGF, Jiang R (2016) Experimental investigation of a molten salt thermocline storage tank. Int J Sustain Energy 35:606–614. https://doi.org/10.1080/14786451.2014.930465

Ferri R, Cammi A, Mazzei D (2008) Molten salt mixture properties in RELAP5 code for thermodynamic solar applications. Int J Therm Sci 47:1676–1687. https://doi.org/10.1016/j.ijthermalsci.2008.01.007

Wu Y, Li Y, Lu Y et al (2017) Novel low melting point binary nitrates for thermal energy storage applications. Sol Energy Mater Sol Cells 164:114–121. https://doi.org/10.1016/j.solmat.2017.02.021

ANSYS Inc (2011). ANSYS fluent user’s guide

Acknowledgments

This work was supported by the National Science Fund for Distinguished Young Scholars (51825605).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhou, H., Shi, H., Zhang, J. et al. Experimental and numerical investigation of temperature distribution and heat loss of molten salt tank foundation at different scales. Heat Mass Transfer 56, 2859–2869 (2020). https://doi.org/10.1007/s00231-020-02905-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-020-02905-x