Abstract

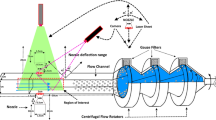

In this paper, a visualization experiment was conducted for multiphase flow in the evaporating hot water tower. The high-speed camera was used to record the motion of a single bubble above the 3 mm single-hole sieve tray in the hot water tower. The pictures were processed by image processing software to obtain the characteristics of the bubble. In the experiment, non-condensable gas was added to the steam as a carrier of particles. A mixture of gaseous N2 and N2/solid particles was used to study the effect of solid particles on bubble formation, collapse and motion processes. The correlation for the number of transfer units NTUL is proposed. The experimental results show that the entire growth cycle of the bubble includes the formation region, the rising region and the oscillation region. The ratio of bubble length to diameter decreases from 1.13 to 0.80 in the formation region and surges to 1.3 in the rising region. The equivalent radius of the bubble increases throughout the entire cycle of motion, with the highest growth rate in the formation region and maximum radius of bubble not exceeding 20 mm. The centroid velocity rate of bubble in the formation region shows an increasing trend, and then fluctuates around 0.4 m/s in the rising region and the oscillation region. When N2 was entrained into the pulverized coal particles, it was found that the proportion of the rising region of the bubble was greatly reduced, and the proportion of the oscillation region increased significantly, which was conducive to the transfer of heat within the tower. The effect is more obvious when steam and nitrogen ratio α is less than 10.

Similar content being viewed by others

Abbreviations

- R :

-

Equivalent radius of bubble, mm

- S :

-

Area of bubble, mm2

- t :

-

Time, ms

- Uy :

-

Centroid velocity of bubble, m·s−1

- α :

-

Steam and nitrogen mass flow ratio

- L :

-

Flow rate of liquid, L·h−1

- G:

-

Flow rate of steam, kg·h−1

- t cond :

-

Steam condensation temperature, °C

- NTU :

-

Number of transfer units

- ρ :

-

Density, kg·m−3

- F P :

-

kinetic energy parameter

- L :

-

Liquid

- G:

-

Gas

- in:

-

inlet

- out:

-

outlet

References

Bergman TL, Incropera FP, Lavine AS (2011) Fundamentals of heat and mass transfer, 7th edn. John Wiley & Sons Inc., New York, pp 673–675

Qu X, Revankar ST, Tian M (2017) Numerical simulation of bubble formation and condensation of steam air mixture injected in subcooled pool. Nucl Eng Des 320:123–132

Mochizuki T, Sato H, Mori YH (2012) Multi-angle observation scheme for bubbles and droplets. J Vis 15(2):125–137

Kamei S, Hirata M (1987) Condensing phenomena of a single vapor bubble into subcooled water. Experimental Heat Transfer 3(2):173–182

Harada T, Nagakura H, Okawa T (2010) Dependence of bubble behavior in subcooled boiling on surface wettability. Nucl Eng Des 240(12):3949–3955

Morita K, Matsumoto T, Fukuda K et al (2008) Experimental verification of the fast reactor safety analysis code SIMMER-III for transient bubble behavior with condensation. Nucl Eng Des 238(1):49–56

Suzuki T, Tobita Y, Yamano H et al (2003) Development of multicomponent vaporization/condensation model for a reactor safety analysis code SIMMER-III: extended verification using multi-bubble condensation experiment. Nucl Eng Des 220(3):240–254

Genić SB (2006) Direct-contact condensation heat transfer on downcommerless trays for steam–water system. Int J Heat Mass Transf 49(7–8):1225–1230

Genić SB, Jaćimović BM, Vladić LA (2008) Heat transfer rate of direct-contact condensation on baffle trays. Int J Heat Mass Transf 51(25–26):5772–5776

Salari E, Peyghambarzadeh SM, Sarafraz MM et al (2017) Thermal behavior of aqueous iron oxide nano-fluid as a coolant on a flat disc heater under the pool boiling condition. Heat Mass Transf 53(1):265–275

Sarafraz MM, Hormozi F, Kamalgharibi M (2014) Sedimentation and convective boiling heat transfer of CuO-water/ethylene glycol nanofluids. Heat Mass Transf 50(9):1237–1249

De Andrés MC, Hoo E, Zangrando F (1996) Performance of direct-contact heat and mass exchangers with steam-gas mixtures at subatmospheric pressures. Int J Heat Mass Transf 39(5):965–973

Sarafraz MM, Shadloo MS, Tian Z et al (2019) Convective bubbly flow of water in an annular pipe: role of total dissolved solids on heat transfer characteristics and bubble formation. Water 11(8):1566

Gulawani SS, Joshi JB, Shah MS et al (2006) CFD analysis of flow pattern and heat transfer in direct contact steam condensation. Chem Eng Sci 61(16):5204–5220

Pan L, Tan Z, Chen D et al (2012) Numerical investigation of vapor bubble condensation characteristics of subcooled flow boiling in vertical rectangular channel. Nucl Eng Des 248(1):126–136

Sachin K, Dahikar SK, Sathe MJ, Joshi JB (2010) Investigation of flow and temperature patterns in direct contact condensation using PIV, PLIF and CFD. Chem Eng Sci 65(16):4606–4620

Tian W, Ishiwatari Y, Ikejiri S et al (2010) Numerical simulation on direct contact condensation of single bubble in subcooled water using MPS method. International Symposium on Multiphase Flow Heat Mass Transfer and Energy Conversion 1207(1):933–938

Zeng Q, Cai J, Yin H et al (2015) Numerical simulation of single bubble condensation in subcooled flow using OpenFOAM. Prog Nucl Energy 83:336–346

Isenberg J, Sideman S (1970) Direct contact heat transfer with change of phase: bubble condensation in immiscible liquids. Int J Heat Mass Transf 13(6):997–1011

Chen YM, Mayinger F (1992) Measurement of heat transfer at the phase interface of condensing bubbles. Int J Multiphase Flow 18(6):877–890

Warrier GR, Basu N, Dhir VK (2002) Interfacial heat transfer during subcooled flow boiling. Int J Heat Mass Transf 45(19):3947–3959

Sadeghi R, Shadloo MS, Hooman K (2016) Numerical investigation of the natural convection film boiling around elliptical tubes. Numerical Heat Transfer, Part A: Applications 70(7):707–722

Chilton TH, Colburn AP (1934) Mass transfer (absorption) coefficients prediction from data on heat transfer and fluid friction. Industrial & engineering chemistry 26(11):1183–1187

Osterle F (1991) On the analysis of counter-flow cooling towers. Int J Heat Mass Transf 34(4–5):1313–1316

Fisenko SP, Brin AA, Petruchik AI (2004) Evaporative cooling of water in a mechanical draft cooling tower. Int J Heat Mass Transf 47:165–177

Sphaier LA, Worek WM (2009) Parametric analysis of heat and mass transfer regenerators using a generalized effectiveness-NTU method. Int J Heat Mass Transf 52:2265–2272

Acknowledgements

This work was supported by Ministry of science and technology of the People’s Republic of China, and under the Research Fund (2017YFB0602802).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Bao, Z., Wang, Y., Hu, C. et al. Effect of solid particles in evaporating hot water tower on bubble movement. Heat Mass Transfer 56, 2445–2456 (2020). https://doi.org/10.1007/s00231-020-02869-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-020-02869-y