Abstract

The effect of spacer orientation on flow behavior is studied at different spacer filament spacings using Computational Fluid Dynamics (CFD) technique. At high inlet velocity / Reynolds number the flow becomes transient and vorticity magnitude increases in a major portion of the two channels. The temperature and heat flux in this case also vary in time. The comparison of various spacer geometrical arrangements/orientations shows that the arrangements in which the spacer filaments are opposite to the membrane layers are more suitable due to higher heat transfer rates. Further appropriate turbulence models for predicting flow and heat transfer behavior in membrane channels are also proposed.

Similar content being viewed by others

Abbreviations

- C p :

-

Specific heat (J/kg·K)

- d f :

-

Filament diameter (m)

- d h :

-

Hydraulic diameter (m)

- h :

-

Heat transfer coefficient (W/m2·K)

- h ch :

-

Channel height (m)

- k t :

-

Thermal conductivity (W/m·K)

- k-ω :

-

Turbulence model, turbulent kinetic energy (m2/s2) and specific dissipation rate (1/s)

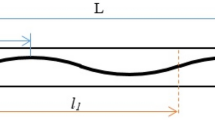

- L :

-

Channel length (m)

- l f :

-

Mesh length / filament spacing (m)

- Nu:

-

Nusselt number

- Pr:

-

Prandtl number

- q w :

-

Heat flux (W/m2)

- Re:

-

Reynolds number

- u av :

-

Average velocity (m/s)

- T b :

-

Bulk temperature (K)

- T m :

-

Temperature at membrane surface (K)

- u :

-

x-component of velocity (m/s)

- v :

-

y-component of velocity (m/s)

- x :

-

x-coordinate (m)

- y :

-

y-coordinate (m)

- ρ :

-

Density (kg/m3)

- μ :

-

Viscosity (kg/m·s)

- ε :

-

Voidage of feed or permeate channel

- εm :

-

Voidage of membrane

- θ :

-

Flow attack angle

References

González D, Amigo J, Suárez F (2017) Membrane distillation: perspectives for sustainable and improved desalination. Renew Sustain Energy Rev 80:238–259

Martínez L, Vázquez-González MI, Florido-Díaz FJ (1998) Study of membrane distillation using channel spacers. J Membr Sci 144:45–46

Alkhudhiri A, Darwish N, Hilal N (2012) Membrane distillation: A comprehensive review. Desalination 287:2–18

Drioli E, Ali A, Macedonio F (2015) Membrane distillation: recent developments and perspectives. Desalination 356:56–84

Mahdi M, Shirazi A, Ismail AF, Matsuura T (2016) Computational fluid dynamic (CFD) opportunities applied to the membrane distillation process: state-of-the-art and perspectives. Desalination 377:73–90

Fimbres-Weihs GA, Wiley DE (2010) Review of 3D CFD modeling of flow and mass transfer in narrow spacer-filled channels in membrane modules. Chem Eng Process 49:759–781

Katsandri A (2017) A theoretical analysis of a spacer filled flat plate membrane distillation modules using CFD: part II: temperature polarisation analysis. Desalination 408:166–180

Chang H, Hsu J, Chang C, Ho C (2015) CFD study of heat transfer enhanced membrane distillation using spacer-filled channels. Energy Procedia 75:3213–3219

Seo J, Kim YM, Kim JH (2017) Spacer optimization strategy for direct contact membrane distillation: shapes, configurations, diameters, and numbers of spacer filaments. Desalination 417:9–18

Martínez L, Rodríguez-Maroto JM (2016) Characterization of membrane distillation modules and analysis of mass flux enhancement by channel spacers. J Membr Sci 274:123–137

Martínez L, Vázquez-González MI, Florido-Díaz FJ (1998) Temperature polarization coefficients in membrane distillation. Sep Sci Technol 33:787–799

Phattaranawik J, Jiraratananon R, Fane AG, Halim C (2001) Mass flux enhancement using spacer filled channel in direct contact membrane distillation. J Membr Sci 187:193–201

Phattaranawik J, Jiraratananon R, Fane AG (2003) Effects of net-type spacers on heat and mass transfer in direct contact membrane distillation and comparison with ultrafiltration studies. J Membr Sci 217:193–206

Chernyshov MN, Meindersma GW, de Haan AB (2005) Comparison of spacers for temperature polarization reduction in air gap membrane distillation. Desalination 183:363–374

Cipollina A, Di Miceli A, Koschikowski J, Micale G, Rizzuti L (2011) CFD simulation of a membrane distillation module channel. Desalin Water Treat 6:177–183

Cipollina A, Di Miceli A, Rizzuti L (2011) Membrane distillation heat transfer enhancement by CFD analysis of internal module geometry. Desalin Water Treat 25:195–209

Al-Sharif S, Albeirutty M, Cipollina A, Micale G (2013) Modelling flow and heat transfer in spacer-filled membrane distillation channels using open source CFD code. Desalination 311:103–112

Soukane S, Naceur MW, Francis L, Alsaadi A, Ghaffour N (2017) Effect of feed flow pattern on the distribution of permeate fluxes in desalination by direct contact membrane distillation. Desalination 418:43–59

Yu H, Yang X, Wang R, Fane AG (2012) Analysis of heat and mass transfer by CFD for performance enhancement in direct contact membrane distillation. J Membr Sci 405-406:38–47

Ahadi H, Karimi-Sabet J, Shariaty-Niassar M, Matsuura T (2018) Experimental and numerical evaluation of membrane distillation module for oxygen-18 separation. Chem Eng Res Des 132:492–504

Guan G, Yao C, Lu S, Jiang Y, Yu H, Yang X (2018) Sustainable operation of membrane distillation for hypersaline applications: roles of brine salinity, membrane permeability and hydrodynamics. Desalination 445:123–137

Eleiwi F, Ghaffour N, Alsaadi AS, Francis L, Laleg-Kirati TM (2016) Dynamic modeling and experimental validation for direct contact membrane distillation (DCMD) process. Desalination 384:1–11

Shakaib M, Hasani SMF, Ahmed I, Yunus RM (2012) A CFD study on the effect of spacer orientation on temperature polarization in membrane distillation modules. Desalination 284:332–340

Jafarkhani M, Moraveji MK, Davarnejad R, Moztarzadeh F, Mozafari M (2012) Three-dimensional simulation of turbulent flow in a membrane tube filled with semi-circular baffles. Desalination 294:8–16

Ranade VV, Kumar A (2005) Fluid dynamics of spacer filled rectangular and curvilinear channels. J Membr Sci 271:1–15

Ahmed S, Seraj MT, Jahedi J, Hashib MA (2011) CFD simulation of turbulence promoters in a tubular membrane channel. Desalination 276:191–198

Ahmad AL, Lau KK, Abu Bakar MZ (2005) Impact of different spacer filament geometries on concentration polarization control in narrow membrane channel. J Membr Sci 262:138–152

Cao Z, Wiley DE, Fane AG (2001) CFD simulations of net-type turbulence promoters in a narrow channel. J Membr Sci 185:157–176

Chen Z, Zhao B, Chen F, Li J (2013) Effect of the flow channel structure on the nanofiltration separation performance. J Nanomater 10:Article ID 132919, 10 pages

Li Y, Tung K, Lu M, Huang S (2009) Mitigating the curvature effect of the spacer-filled channel in a spiral-wound membrane module. J Membr Sci 329:106–118

Lawson KW, Lloyd DR (1997) Membrane distillation. J Membr Sci 124:1–25

Shakaib M, Ahmed I, Yunus RM (2011) Effect of permeation velocity on flow behavior and pressure drop in feed channels of membranes. In: ASEAN conference on scientific and social science research (ACSSSR2011)

White FM (2006) Viscous fluid flow, 3rd edn. McGraw-Hill, Boston

Schock G, Miquel A (1987) Mass transfer and pressure loss in spiral wound modules. Desalination 64:339–352

Acknowledgements

The support provided by NED University of Engineering and Technology, Karachi, Pakistan is acknowledged.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Shakaib, M., Haque, M.Eu. Numerical simulations for fluid dynamics and temperature patterns in membrane distillation channels. Heat Mass Transfer 55, 3509–3522 (2019). https://doi.org/10.1007/s00231-019-02678-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-019-02678-y