Abstract

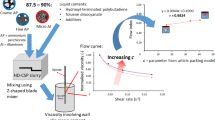

The current research aims at investigating role of three different types of surfactants and their binary mixtures in producing high cooling rate during jet impingement on a hot steel plate (100 mm × 100 mm × 6 mm) having initial surface temperature above 900 °C. The surfactants used are Sodium dodecyl sulphate (anionic), cetyltrimethylammonium bromide (cationic) and Polysorbate 20 (Tween 20, non-ionic). The surface tension values of the surfactants and their mixed systems have been measured and it has been observed that the binary mixtures at specific compositions show lower surface tension compared to the pure ones mainly due to synergism. The cooling results reveal that the mixture of cationic and non-ionic surfactants produces the highest cooling rate amongst all the systems. The maximum cooling rate achieved is 182 °C/s for the composition of 25 vol% CTAB and 75 vol% Tween 20 and it is 67% more than that of pure water, 23% more compared to pure CTAB and and 7.7% more than that of pure Tween 20. Thus it can be seen that ultrafast cooling of a 6 mm thick steel plate can be achieved by using optimized concentrations of mixed surfactant additives and this leads to improvement of quality of steel produced.

Similar content being viewed by others

Abbreviations

- T1:

-

Thermocouple 1

- T2:

-

Thermocouple 2

- T3:

-

Thermocouple 3

- x:

-

Direction along the length of the plate (mm)

- y:

-

Direction along the thickness of the plate (mm)

- z:

-

Direction along the depth of the plate (mm)

- α:

-

Thermal diffusivity of steel (m2/s)

- Z1:

-

Heat flux zone 1

- Z2:

-

Heat flux zone 2

- Z3:

-

Heat flux zone 3

- ROT:

-

Run out table

- UFC:

-

Ultrafast cooling

- SDS:

-

Sodium dodecyl sulphate

- CTAB:

-

Cetyltrimethylammonium bromide

- Tween 20:

-

Polysorbate 20

- AISI:

-

American iron and steel institute

- ASME:

-

American society of mechanical engineers

References

Delagnes D, Rézaï-Aria F, Levaillant C (2010) Influence of testing and tempering temperatures on fatigue behaviour, life and crack initiation mechanisms in a 5%Cr martensitic steel. Procedia Engineering 2:427–439. https://doi.org/10.1016/j.proeng.2010.03.047

Ravikumar SV, Jha JM, Sarkar I, Pal SK, Chakraborty S (2014) Enhancement of heat transfer rate in air-atomized spray cooling of a hot steel plate by using an aqueous solution of non-ionic surfactant and ethanol. Appl Therm Eng 64:64–75. https://doi.org/10.1016/j.applthermaleng.2013.12.008

Jong Cho M, Thomas B, Jong Lee P (2008) Three-Dimensional Numerical Study of Impinging Water Jets in Runout Table Cooling Processes. The Minerals, Metals & Materials Society and ASM International 39:593–602. https://doi.org/10.1007/s11663-008-9160-8

Mohapatra SS, Ravikumar SV, Verma A, Pal SK, Chakraborty S (2013) Experimental Investigation of Effect of a Surfactant to Increase Cooling of Hot Steel Plates by a Water Jet. J Heat Transf 135:032101–032107. https://doi.org/10.1115/1.4007878

Ravikumar SV, Jha JM, Mohapatra SS, Pal SK, Chakraborty S (2014) Experimental Investigation of Effect of Different Types of Surfactants and Jet Height on Cooling of a Hot Steel Plate. J Heat Transf 136:072102–072110. https://doi.org/10.1115/1.4027182

Sarkar I, Behera DK, Jha JM, Pal SK, Chakraborty S (2016) Effect of polymer additive on the cooling rate of a hot steel plate by using water jet. Exp Thermal Fluid Sci 70:105–114. https://doi.org/10.1016/j.expthermflusci.2015.08.012

Oliphant K, Webb B, McQuay M (1998) An experimental comparison of liquid jet array and spray impingement cooling in the non-boiling regime. Exp Thermal Fluid Sci 18:1–10

Zumbrunnen D (1990) Method and apparatus for measuring heat transfer distributions on moving and stationary plates cooled by a planar liquid jet. Exp Thermal Fluid Sci 3:202–213

Al-Ahmadi HM, Yao SC (2008) Spray cooling of high temperature metals using high mass flux industrial nozzles. Experimental Heat Transfer 21:38–54. https://doi.org/10.1080/08916150701647827

Wendelstorf J, Spitzer KH, Wendelstorf R (2008) Spray water cooling heat transfer at high temperatures and liquid mass fluxes. Int J Heat Mass Transf 51:4902–4910. https://doi.org/10.1016/j.ijheatmasstransfer.2008.01.032

Jha JM, Ravikumar SV, Sarkar I, Pal SK, Chakraborty S (2015) Ultrafast cooling processes with surfactant additive for hot moving steel plate. Exp Thermal Fluid Sci 68:135–144. https://doi.org/10.1016/j.expthermflusci.2015.04.004

Chandra S, di Marzo M, Qiao YM, Tartarini P (1996) Effect of liquid-solid contact angle on droplet evaporation. Fire Saf J 27:141–158. https://doi.org/10.1016/S0379-7112(96)00040-9

Qiao YM, Chandra S (1997) Experiments on adding a surfactant to water drops boiling on a hot surface. Proceedings of the Royal Society of London Series A: Mathematical, Physical and Engineering Sciences 453:673–689. https://doi.org/10.1098/rspa.1997.0038

Stoebe T, Lin Z, Hill RM, Ward MD, Davis HT (1996) Surfactant-Enhanced Spreading. Langmuir 12:337–344. https://doi.org/10.1021/la950513x

Mohapatra SS, Jha JM, Srinath K, Pal SK, Chakraborty S (2014) Enhancement of Cooling Rate for a Hot Steel Plate using Air-Atomized Spray with Surfactant-Added Water. Experimental Heat Transfer 27:72–90. https://doi.org/10.1080/08916152.2012.719068

Ravikumar SV, Jha JM, Sarkar I, Mohapatra SS, Pal SK, Chakraborty S (2013) Achievement of ultrafast cooling rate in a hot steel plate by air-atomized spray with different surfactant additives. Exp Thermal Fluid Sci 50:79–89. https://doi.org/10.1016/j.expthermflusci.2013.05.007

Stocco A, Carriere D, Cottat M, Langevin D (2010) Interfacial Behavior of Catanionic Surfactants. Langmuir 26:10663–10669. https://doi.org/10.1021/la100954v

Upadhyaya A, Acosta EJ, Scamehorn JF, Sabatini DA (2006) Microemulsion phase behavior of anionic-cationic surfactant mixtures: Effect of tail branching. J Surfactant Deterg 9:169–179. https://doi.org/10.1007/s11743-006-0387-6

Wasekar VM (2009) Heat transfer in nucleate pool boiling of aqueous SDS and triton X-100 solutions. Heat Mass Transf 45:1409–1414. https://doi.org/10.1007/s00231-009-0517-6

Kume G, Gallotti M, Nunes G (2008) Review on Anionic/Cationic Surfactant Mixtures. J Surfactant Deterg 11:1–11. https://doi.org/10.1007/s11743-007-1047-1

Khan A, Marques EF (1999) Synergism and polymorphism in mixed surfactant systems. Curr Opin Colloid Interface Sci 4:402–410. https://doi.org/10.1016/S1359-0294(00)00017-0

Bramer T, Dew N, Edsman K (2007) Pharmaceutical applications for catanionic mixtures. J Pharm Pharmacol 59:1319–1334. https://doi.org/10.1211/jpp.59.10.0001

Rosen MJ, Hua XY (1982) Synergism in binary mixtures of surfactants: II. Some experimental data. Journal of the American Oil Chemists Society 59:582–585. https://doi.org/10.1007/bf02636329

Zhu BY, Rosen MJ (1984) Synergism in binary mixtures of surfactants: IV. Effectiveness of surface tension reduction. J Colloid Interface Sci 99:435–442. https://doi.org/10.1016/0021-9797(84)90130-9

Suryanarayana G, Ghosh P (2010) Adsorption and Coalescence in Mixed-Surfactant Systems: Air−Water Interface. Ind Eng Chem Res 49:1711–1724. https://doi.org/10.1021/ie9012216

Goloub TP, Pugh RJ, Zhmud BV (2000) Micellar Interactions in Nonionic/Ionic Mixed Surfactant Systems. J Colloid Interface Sci 229:72–81. https://doi.org/10.1006/jcis.2000.6954

Ravikumar SV, Jha JM, Sarkar I, Pal SK, Chakraborty S (2014) Mixed-surfactant additives for enhancement of air-atomized spray cooling of a hot steel plate. Exp Thermal Fluid Sci 55:210–220. https://doi.org/10.1016/j.expthermflusci.2014.03.007

Okano T, Tamura T, Abe Y, Tsuchida T, Lee S, Sugihara G (2000) Micellization and Adsorbed Film Formation of a Binary Mixed System of Anionic/Nonionic Surfactants. Langmuir 16:1508–1514. https://doi.org/10.1021/la990331t

Rosen MJ (2005) Mechanism of the enhanced spreading of some mixtures of anionic and cationic hydrocarbon chain surfactants on a highly hydrophobic polyethylene surface. J Surfactant Deterg 8:157–163. https://doi.org/10.1007/s11743-005-341-7

Li DI, Wells MA (2005) Effect of subsurface thermocouple installation on the discrepancy of the measured thermal history and predicted surface heat flux during a quench operation. Metall Mater Trans B Process Metall Mater Process Sci 36:343–354. https://doi.org/10.1007/s11663-005-0064-6

Trujillo DM, Busby HR (1997) Practical Inverse Analysis in Engineering. CRC Press, Boca Raton, p 235

Jha JM, Ravikumar SV, Tiara AM, Sarkar I, Pal SK, Chakraborty S (2015) Ultrafast cooling of a hot moving steel plate by using alumina nanofluid based air atomized spray impingement. Appl Therm Eng 75:738–747. https://doi.org/10.1016/j.applthermaleng.2014.10.005

Sarkar I, Chakraborty S, Jha JM, Pal SK, Chakraborty S (2017) Ultrafast cooling of a hot steel plate using Cu-Al layered double hydroxide nanofluid jet. Int J Therm Sci 116:52–62. https://doi.org/10.1016/j.ijthermalsci.2017.02.009

Ravikumar SV, Haldar K, Jha JM, Chakraborty S, Sarkar I, Pal SK, Chakraborty S (2015) Heat transfer enhancement using air-atomized spray cooling with water–Al2O3 nanofluid. Int J Therm Sci 96:85–93. https://doi.org/10.1016/j.ijthermalsci.2015.04.012

Tiara AM, Chakraborty S, Sarkar I, Pal SK, Chakraborty S (2017) Effect of alumina nanofluid jet on the enhancement of heat transfer from a steel plate. Heat Mass Transf 53:2187–2197. https://doi.org/10.1007/s00231-016-1955-6

Wang Y, Pereira CM, Marques EF, Brito RO, Ferreira ES, Silva F (2006) Catanionic surfactant films at the air–water interface. Thin Solid Films 515:2031–2037. https://doi.org/10.1016/j.tsf.2006.04.044

Jönsson B, Jokela P, Khan A, Lindman B, Sadaghiani A (1991) Catanionic Surfactants: Phase Behavior and Microemulsions. Langmuir 7:889–895. https://doi.org/10.1021/la00053a013

Hua XY, Rosen MJ (1982) Synergism in binary mixtures of surfactants: I. Theoretical analysis. J Colloid Interface Sci 90:212–219. https://doi.org/10.1016/0021-9797(82)90414-3

Jadidi N, Adib B, Malihi FB (2013) Synergism and Performance Optimization in Liquid Detergents Containing Binary Mixtures of Anionic–Nonionic, and Anionic–Cationic Surfactants. J Surfactant Deterg 16:115–121. https://doi.org/10.1007/s11743-012-1371-y

Abernethy RB, Benedict RP, Dowdell RB (1985) ASME Measurement Uncertainty. J Fluids Eng 107:161–164. https://doi.org/10.1115/1.3242450

Tiara AM, Chakraborty S, Sarkar I, Ashok A, Pal SK, Chakraborty S (2017) Heat transfer enhancement using surfactant based alumina nanofluid jet from a hot steel plate. Exp Thermal Fluid Sci 89:295–303. https://doi.org/10.1016/j.expthermflusci.2017.08.023

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sarkar, I., Jha, J.M., Priyanka, V. et al. Application of binary mixed surfactant additives in jet impingement cooling of a hot steel plate. Heat Mass Transfer 55, 3413–3425 (2019). https://doi.org/10.1007/s00231-019-02665-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-019-02665-3