Abstract

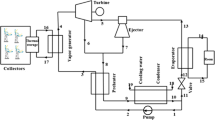

The energy performance of a direct expansion solar assisted heat pump system, working with a hydrocarbon mixture (HCM) of R290/R1270, 70:30 (by mass ratio) was investigated. The experiments were carried out at a metrological condition existing near Calicut, India. The experimental system mainly consists of a compressor, condenser, thermostatic expansion valve and evaporator collector. A system simulation technique was used for modelling the system. The experimental results obtained are compared with simulation output of the system working with R22 and a mixture of R290/R1270. The selected alternative working fluid mixture showed better energy performance ratio about 5.8% higher. The parametric analysis of the system working with R22 and a mixture of R290/R1270 is investigated with the help of an established system simulation model. The effect of an evaporator (solar collector) area and solar insolation are found to be the significant influencing parameters on the system performance. Moreover, the new hydrocarbon mixture is found to be a good energy efficient and environmental friendly working fluid to phase out R22 in the solar assisted heat pump systems.

Similar content being viewed by others

Abbreviations

- A c :

-

area of collector (m2)

- C p a :

-

specific heat of air (kJ Kg− 1 K− 1)

- d f :

-

dust factor

- D :

-

diameter of the tube (m)

- HCM :

-

hydrocarbon mixture

- I t :

-

total solar Insolation (W m− 2)

- ṁ:

-

mass flow rate (kg s− 1)

- P :

-

compressor power consumption (W)

- q c :

-

condenser heating capacity (W)

- q e :

-

heat absorbed by evaporator (W)

- S :

-

solar Insolation (W m− 2)

- T :

-

temperature (0C)

- U w :

-

wind speed (m s− 1)

- U o :

-

heat transfer coefficient (W m− 2)

- W :

-

width of tube (m)

- x :

-

thickness of insulation (m)

- a :

-

air

- amb :

-

ambient

- b ′ :

-

bottom

- c :

-

condenser

- dp :

-

dew point

- e :

-

evaporator

- e ′ :

-

edge

- p :

-

plate

- r :

-

refrigerant

- s :

-

sky

- t ′ :

-

top

- α :

-

absorptance plate material

- δ p :

-

thickness of plate (m)

- λ p :

-

thermal conductivity plate (W m− 1 K− 1)

References

Ito S, Miura N, Takano Y (2005) Studies of heat pumps using direct expansion type solar collectors. J Solar Energy ASME Trans 127:60–64

Ozgener O, Hepbasli A (2007) Modeling and performance evaluation of ground source (geothermal) heat pump systems. Energy Build 39:66–75

Ozgener O, Hepbasli A (2005) Performance analysis of a solar-assisted ground-source heat pump system for greenhouse heating: an experimental study. Build Environ 8:1040–1050

Ozgener O, Hepbasli A (2005) Experimental investigation of the performance of a solar-assisted ground-source heat pump system for greenhouse heating. Int J Energy Res 29:217–231

Li Y, Wang R, Wu J, Xu Y (2007) Experimental performance analysis on a direct expansion solar-assisted heat pump water heater. Appl Therm Eng 27:2858–2868

Hawlader M, Jahangeer K (2006) Solar heat pump drying and water heating in the tropics. Sol Energy 80:492–499

Li Y, Li H, Dai Y, Gao S, Wei L, Li Z, Odinez I, Wang R (2011) Experimental investigation on a solar assisted heat pump in-store drying system. Appl Therm Eng 31:1718–1724

Hawlader M, Dey P K, Diab S, Chung C Y (2004) Solar assisted heat pump desalination system. Desalination 168:49–54

Mohanraj M, Jayaraj S, Muraleedharan C (2011) A review on recent developments in new refrigerant mixtures for vapour compression-based refrigeration, air-conditioning and heat pump units. Int J Energy Res 35:647–669

Mohanraj M, Jayaraj S, Muraleedharan C (2009) Environment friendly alternatives to halogenated refrigerants—A review. Int J Greenhouse Gas Control 3:108–119

Chang Y, Kim M, Ro S (2000) Performance and heat transfer characteristics of hydrocarbon refrigerants in a heat pump system. Int J Refrig 23:232–242

Chaichana C, Aye L, Charters W (2003) Natural working fluids for solar-boosted heat pumps. Int J Refrig 26:637–643

Park K J, Seo T, Jung D (2007) Performance of alternative refrigerants for residential air conditioning applications. Appl Energy 84:985–991

Park K J, Shim Y B, Jung D (2008) Performance of R433A for replacing HCFC22 used in residential air-conditioners and heat pumps. Appl Therm Eng 85:896–900

Park K J, Shim Y B, Jung D (2009) Experimental performance of R432A to replace R22 in residential air-conditioners and heat pumps. Appl Therm Eng 29:597–600

Chata F G, Chaturvedi S, Almogbel A (2005) Analysis of a direct expansion solar assisted heat pump using different refrigerants. Energy Convers Manag 46:2614–2624

Khorasaninejad E, Hajabdollahi H (2014) Thermo-economic and environmental optimization of solar assisted heat pump by using multi-objective particle swam algorithm. Energy 72:680–690

Malinaroli L, Joppolo C M, Antonellis S D (2014) Numerical analysis of the use of R407C in direct expansion solar assisted heat pump. Energy Procedia 48:938–945

Aprea C, Mastrullo R, Renno C (2004) An analysis of the performance of vapor compression plant working both as water chiller and heat pump using R22 and R417A. Appl Thermal Energy 24:487–499

Jabaraj D B, Avinash P, Mohanlal D, Renganarayanan S (2006) Experimental investigation of HFC407C/HC290/HC600a mixture in window air conditioner. Energy Convers Manag 47:2578–2590

Mohanraj M, Jayaraj S, Muraleedharan C (2009) A comparison of the performance of a direct expansion solar-assisted heat pump working with R22 and R407C/Liquid petroleum gas. Proc Ins Mech Eng Part A: J Power Energy 1:223–821

Mohanraj M, Jayaraj S, Muraleedharan C (2010) Exergy Assessment of a Direct Expansion Solar-Assisted Heat Pump Working with R22 and R407C/LPG Mixture. Int J Green Energy 7:65–83

Mohanraj M, Jayaraj S, Muraleedharan C (2008) Modeling of a direct expansion solar assisted heat pump using artificial neural networks. Int J Green Energy 5:520–532

Mohanraj M, Jayaraj S, Muraleedharan C (2009) Performance prediction of a direct expansion solar assisted heat pump using artificial neural networks. Appl Energy 86:1442–1449

Shariah A, Al-Akhras M A, Al-Omari I A (2002) Optimizing the tilt angle of solar collectors. Renew Energy 26:587–598

Holman JP (2007) Experimental methods for engineers, 4th edn. Tata McGraw Hill Publishing Company Limited, New Delhi

Duffie J A, Beckman W A (1980) Solar engineering of thermal processes, 1st edn. Wiley, New York

Sukhatme SP (1984) Solar energy principles of thermal collection and storage, 2nd edn. Tata Mac Graw Hill Publications, New Delhi

Prakash G, Garg HP (2000) Solar energy: Fundamentals and applications, 2nd edn. Tata Mac Graw Hill Publications, New Delhi

Tiwari GN (2002) Solar energy: Fundamentals, design, modelling and applications, 2nd edn. CRC Press, New Delhi

Dincer I, Kanoglu M (2010) Refrigeration systems and applications, 2nd edn. Wiley, New York

Arora CP (2000) Refrigeration and air conditioning, 2nd edn. Tata McGraw-Hill Publications, New Delhi

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Paradeshi, L., Srinivas, M. & Jayaraj, S. Performance of hydrocarbon mixture in a direct expansion solar assisted heat pump system. Heat Mass Transfer 55, 965–977 (2019). https://doi.org/10.1007/s00231-018-2475-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-018-2475-3