Abstract

The present work deals with experimental investigation of heat transfer and fluid flow characteristics of multiple square perforated twisted tape with wing inserts in a heat exchanger tube. The range of selected geometrical parameters are, perforation width ratio (a/WT) of 0.083–0.333, twist ratio (TL/WT) of 2.0–3.5, wing depth ratio (Wd/WT) of 0.042–0.167 and number of twisted tapes (TP) of 4. The Reynolds number (Ren) selected for experimentation ranges from 5000 to 27,000. The maximum heat transfer and friction factor enhancement was found to be 6.96 and 8.34 times that of plane tube, respectively. The maximum heat transfer enhancement is observed at a a/WT of 0.250, TL/WT of 2.5, and Wd/WT of 0.167.

Similar content being viewed by others

Abbreviations

- a :

-

Perforated width, m.

- a/W T :

-

Perforation width ratio, dimensionless

- A o :

-

Area of orifice plate, m2

- A p :

-

Area of pipe, m2

- C p :

-

Specific heat, J/kg K

- C d :

-

Coefficient of discharge, dimensionless

- D :

-

Hydraulic diameter of pipe, m

- f rs :

-

Friction factor rough surface, dimensionless

- f ss :

-

Friction factor plain tube, dimensionless

- H :

-

Head difference, m

- h :

-

Heat transfer coefficient, W/m2 K

- k :

-

Thermal conductivity of air, W/m K

- L :

-

Tube length, m

- \( \dot{m} \) :

-

Mass flow rate, kg/s

- Nu rs :

-

Nusselt number rough tube, dimensionless

- Nu ss :

-

Nusselt number plain tube, dimensionless

- (∆P) o :

-

Pressure drop across orifice plate, Pa

- (∆P) d :

-

Pressure drop according to Darcy’s equation, Pa

- ∆P :

-

Pressure drop, Pa

- Pr :

-

Prandtl number, dimensionless

- Q u :

-

Useful heat transfer, W

- Re n :

-

Reynolds number, dimensionless

- T pm :

-

Mean pipe temperature, K

- T fm :

-

Mean fluid temperature, K

- T i :

-

Inlet temperature, K

- T o :

-

Outlet temperature, K

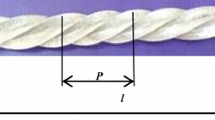

- T L :

-

Twist length, m

- T L /W T :

-

Twist ratio, dimensionless

- V :

-

Air flow velocity, m/s

- W T :

-

Width of tape, m

- W d :

-

Wing depth, m

- W d /W T :

-

Wing depth ratio, dimensionless

- PCR :

-

Perforated conical ring

- WPT :

-

Winglet perforated tapes

- β :

-

Orifice diameter to the pipe diameter ratio, dimensionless

- ρ :

-

Density, kg/m3

- η :

-

Performance evaluation factor, dimensionless

References

Kumar R, Chauhan R, Muneesh S, Kumar A (2017) Experimental study and correlation development for Nusselt number and friction factor for discretized broken V-pattern baffle solar air channel. Exp Thermal Fluid Sci 81:56–75

Kumar A, Kim MH (2016) Thermal hydraulic performance in a solar air heater channel with multi v-type perforated baffles. Energies 9:564

Kumar A, Kim MH (2015) Mathematical simulation on thermal performance of packed bed solar energy storage system. Trans of the Korean Hydrogen and New Energy Societyvol 81:331–338

Eiamsa-ard S, Nuntadusit C, Promvonge P (2013) Effect of Twin Delta-Winged Twisted-Tape on Thermal Performance of Heat Exchanger Tube. Heat Transfer. Engineering 34:1278–1288

Murugesan P, Mayilsamy K, Suresh S (2011) Heat Transfer in Tubes Fitted with Trapezoidal-Cut and Plain Twisted Tape Inserts. Chem Eng Commun 198:886–904

Eiamsa-ard S, Thianpong C, Eiamsa-ard P, Promvonge P (2010) Thermal characteristics in a heat exchanger tube fitted with dual twisted tape elements in tandem. International Communications in Heat and Mass Transfer 37:39–46

Eiamsa-ard S, Thianpong C, Promvonge P (2006) Experimental investigation of heat transfer and flow friction in a circular tube fitted with regularly spaced twisted tape elements. International Communications in Heat and Mass Transfer 33:1225–1233

Sarada SN, Raju ASR, Radha KK, Sunder LS (2010) Enhancement of heat transfer using varying width twisted tape inserts. Int J Eng Sci Technol 2:45–56

Eiamsa-ard S (2010) Study on thermal and fluid flow characteristics in turbulent channel flows with multiple twisted tape vortex generators. International Communications in Heat and Mass Transfer 37:644–651

Eiamsa-ard S, Nanan K, Wongcharee K, Yongsiri K, Thianpong C (2014) Thermohydraulic Performance of Heat Exchanger Tube Equipped with Single-, Double-, and Triple-Helical Twisted Tapes. Chem Eng Commun 202:606–615

Vashistha C, Patil AK, Kumar M (2016) Experimental investigation of heat transfer and pressure drop in a circular tube with multiple inserts. Appl Therm Eng 96:117–129

Thianpong C, Eiamsa-ard P, Eiamsa-ard S (2011) Heat transfer and thermal performance characteristics of heat exchanger tube fitted with perforated twisted-tapes. Heat Mass Transf 48:881–892

Gunes S, Karakaya E (2015) Thermal Characteristics in a Tube With Loose-Fit Perforated Twisted Tapes. Heat Transfer. Engineering 36:1504–1517

Shabanian SR, Rahimi M, Shahhosseini M, Alsairafi AA (2011) CFD and experimental studies on heat transfer enhancement in an air cooler equipped with different tube inserts. International Communications in Heat and Mass Transfer 38:383–390

Eiamsa-ard S, Promvonge P (2010) Thermal characteristics in round tube fitted with serrated twisted tape. Appl Therm Eng 30:1673–1682

Kongkaitpaiboon V, Nanan K, Eiamsa-ard S (2010) Experimental investigation of heat transfer and turbulent flow friction in a tube fitted with perforated conical-rings. International Communications in Heat and Mass Transfer 37:560–567

Wen TJ, Anthony MJ, Ya LH, Wen QT (2015) Summary and evaluation on single-phase heat transfer enhancement techniques of liquid laminar and turbulent pipe flow. Int J Heat Mass Transf 88:735–754

Wen TJ, Anthony MJ, Ya LH, Wen QT (2017) Summary and evaluation on the heat transfer enhancement techniques of gas laminar and turbulent pipe flow. Int J Heat Mass Transf 111:467–483

Thianpong C, Eiamsa-ard P, Promvonge P, Eiamsa-ard S (2012) Effect of perforated twisted-tapes with parallel wings on heat tansfer enhancement in a heat exchanger tube. Energy Procedia 14:1117–1123

Nanan K, Thianpong C, Promvonge P, Eiamsa-ard S (2014) Investigation of heat transfer enhancement by perforated helical twisted-tapes. International Communications in Heat and Mass Transfer 52:106–112

Guo J, Fan A, Zhang X, Liu W (2011) A numerical study on heat transfer and friction factor characteristics of laminar flow in a circular tube fitted with center-cleared twisted tape. Int J Therm Sci 50:1263–1270

Skullong S, Promvonge P, Thianpong C, Pimsarn M (2016) Heat transfer and turbulent flow friction in a round tube with staggered-winglet perforated-tapes. Int J Heat Mass Transf 95:230–242

Manglik RM, Bergles AE (1992) Heat transfer enhancement and pressure drop in viscous liquid flows in isothermal tubes with twisted tape inserts. Warme und Stoffubertragung 27:249–257

Manglik R. M, Bergles A. E (1993a) Heat transfer and pressure drop correlations for twisted tape inserts in isothermal tubes part1-laminar flows. J Heat Transf, 115: 881-889

Manglik RM, Bergles AE (1993b) Heat transfer and pressure drop correlations for twisted tape inserts in isothermal tubes part II-Transition and turbulent flows. J Heat Transf 115:890–896

Sivashanmugam P, Suresh S (2006) Experimental studies on heat transfer and friction factor characteristics of laminar flow through a circular tube fitted with helical screw-tape inserts. Appl Therm Eng 26:1990–1997

Sivashanmugam P, Nagarajan PK (2007) Studies on heat transfer and friction factor characteristics of laminar flow through a circular tube fitted with right and left helical screw-tape inserts. Exp Thermal Fluid Sci 32:192–197

Chang SW, Yang TL, Liou JS (2007) Heat transfer and pressure drop in tube with broken twisted tape insert. Exp Thermal Fluid Sci 32:489–501

Ahamed JU, Wazed MA, Ahmed S, Nukman YT, Ya TMYST, Sarkar MAR (2011) Enhancement and prediction of heat transfer rate in turbulent flow through tube with perforated twisted tape inserts: A new correlation. J Heat Transf 133:041903–041903

Murugesan P, Mayilsamy K, Suresh S, Srinivasan PSS (2011) Heat transfer and pressure drop characteristics in a circular tube fitted with and without V-cut twisted tape insert. International Communications in Heat and Mass Transfer 38:329–334

Sharma PK, Suramanyam T, Kishore PS, Dharma Rao V, Kakac S (2003) Laminar convective heat transfer with twisted tape inserts in a tube. Int J Therm Sci 42:821–828

Rahimi M, Shabanian SR, Alsairafi AA (2009) Experimental and CFD studies on heat transfer and friction factor characteristics of a tube equipped with modified twisted tape inserts. Chem Eng Process Process Intensif 48:762–770

Saha SK, Dutta A, Dhal SK (2001) Friction and heat transfer characteristics of laminar swirl flow through a circular tube fitted with regularly spaced twisted-tape elements. Int J Heat Mass Transf 44:4211–4223

Bhuiya MMK, Azad AK, Chowdhury MSU, Saha M (2016) Heat transfer augmentation in a circular tube with perforated double counter twisted tape inserts. International Communications in Heat and Mass Transfer 74:18–26

Bhuiya MMK, Chowdhury MSU, Saha M, Islam MT (2013) Heat transfer and friction factor characteristics in turbulent flow through a tube fitted with perforated twisted tape inserts. International Communications in Heat and Mass Transfer 46:49–57

Wongcharee W, Eiamsa-ard S (2011) Heat transfer enhancement by twisted tapes with alternate-axes and triangular, rectangular and trapezoidal wings. Chem Eng Process Process Intensif 50:211–219

Eiamsa-ard S, Wongcharee K, Eiamsa-ard P, Thianpong C (2010) Thermohydraulic investigation of turbulent flow through a round tube equipped with twisted tapes consisting of centre wings and alternate-axes. Exp Thermal Fluid Sci 34:1151–1161

Eiamsa-ard S, Pimsarn M, Thianpong C (2015) Performance assessment in a heat exchanger tube with opposite/parallel wing twisted tapes. Advances in. Mech Eng 7:652536

Ji W-T, Jacobi AM, He Y-L, Tao W-Q (2015) Summary and evaluation on single-phase heat transfer enhancement techniques of liquid laminar and turbulent pipe flow. Int J Heat Mass Transf 88:735–754

Ji W-T, Jacobi AM, He Y-L, Tao W-Q (2017) Summary and evaluation on the heat transfer enhancement techniques of gas laminar and turbulent pipe flow. Int J Heat Mass Transf 111:467–483

Klein SJ, Mc Clintock A (1953) The description of uncertanties in a single sample experiments. Mech Eng 75:3–8

Lewis MJ (1975) Optimizing the thermohydraulic performance of rough surfaces. Int J Heat Mass Transf 18:1243–1248

Webb RLand Eckert ERG (1972) Application of rough surface to heat exchanger design. International Journal Heat and Mass Transfer 15:1647–1658

Author information

Authors and Affiliations

Corresponding author

Appendix

Appendix

Mass flow rate:

Hence, uncertainty in mass flow rate measurement is 2.57%.

Heat gain:

Hence, uncertainty in heat gain is 2.77%.

Heat transfer coefficient:

Hence, uncertainty in heat transfer coefficient is 2.84%.

Reynolds number:

Hence, uncertainty Reynolds Number is 1.23%.

Nusselt number:

Hence, uncertainty Nusselt Number is 2.84%.

Friction factor

Hence, uncertainty Friction Factor is 1.33%.

Rights and permissions

About this article

Cite this article

Suri, A.R.S., Kumar, A. & Maithani, R. Experimental investigation of heat transfer and fluid flow behaviour in multiple square perforated twisted tape with square wing inserts heat exchanger tube. Heat Mass Transfer 54, 1813–1826 (2018). https://doi.org/10.1007/s00231-018-2290-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-018-2290-x