Abstract

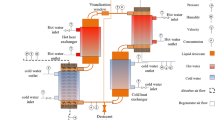

In this paper, transient performance of the previously introduced natural convection heat and mass transfer loop is investigated for an air dehumidifier system. The performance of the loop is studied in different conditions of heat source/heat sink temperature and different startup desiccant concentrations. Unlike conventional loops, it is observed that natural convection of the fluid originates from the heat sink towards the heat source. The proper operation of the cycle is highly dependent on the heat sink/heat source temperatures. To reduce the time constant of the system, a proper desiccant concentration should be adopted for charge of the loop.

Similar content being viewed by others

Abbreviations

- C :

-

Concentration (kgsalt/kgsolution)

- down:

-

Lower horizontal level

- P :

-

Pressure (kPa)

- T :

-

Temperature (°C)

- up:

-

Upper horizontal level

- \(\dot{V}\) :

-

Volume flow rate (l/h)

- AC:

-

Air conditioning

- ASTM:

-

American society of testing machines

- CaCl2 :

-

Calcium chloride

- HFM:

-

Hollow fiber membrane

- IAQ:

-

Indoor air quality

- LAMEE:

-

Liquid to air membrane energy exchanger

- LDAC:

-

Liquid desiccant air conditioning system

- LiBr:

-

Lithium bromide

- LiCl:

-

Lithium chloride

- MgCl2 :

-

Magnesium chloride

- NCLD:

-

Natural convection liquid desiccant

- PE:

-

Poly ethylene

- PIV:

-

PARTICLE image velocimetry

- PP:

-

Poly propylene

- PVDF:

-

Poly vinylidene fluoride

- RTD:

-

Resistance temperature detector

- TEG:

-

Tri-ethylene glycol

- db:

-

Dry bulb

- wb:

-

Wet bulb

References

Zhang LZ (2008) Total heat recovery: heat and moisture recovery from ventilation air. Nova Science Publishing Co., New York

Abdel-Salam MRH, Fauchoux M, Ge G, Besant RW, Simonson CJ (2014) Expected energy and economic benefits, and environmental impacts for liquid-to-air membrane energy exchangers (LAMEEs) in HVAC systems: a review. Appl Energy 127:202–218

ENPI—Neighborhood—Mediterranean and Eastern Europe. Identification mission for the mediterranean solar plan. Final Report, January 2010, FWC beneficiaries Lot4—No. 008/168828; January 2010. http://ec.europa.eu/energy/international/international_cooperation/doc/2010_01_solar_plan_report.pdf

Ge G, Abdel-Salam MRH, Besant RW, Simonson CJ (2013) Research and applications of liquid-to-air membrane energy exchangers in building HVAC systems at university of Saskatchewan: a review. Renew Sustain Energy Rev 26:464–479

World energy outlook 2012: executive summary, International energy agency, IEA http://www.worldenergyoutlook.org (2012)

Al-Abidi AA, Mat SB, Sopian K, Sulaiman MY, Lim CH, Abdulrahman Th (2012) Review of thermal energy storage for air conditioning systems. Renew Sustain Energy Rev 16:5802–5819

Hao X, Zhu C, Lin Y, Wang H, Zhang G, Chen Y (2013) Optimizing the pad thickness of evaporative air-cooled chiller for maximum energy saving. Energy Build 61:146–152

Awbi HB (1998) Chapter 7—ventilation. Renew Sustain Energy Rev 2:157–188

Spengler JD, Sexton K (1983) Indoor air pollution: a public health perspective. Science 221(4605):9–17

Dimitroulopoulou C (2012) Ventilation in Europe and wellings: a review. Build Environ 47:109–125

Simonson C (2005) Energy consumption and ventilation performance of a naturally ventilated ecological house in a cold climate. Energy Build 37:23–35

Abdel-Salam AH, Simonson CJ (2014) Annual evaluation of energy, environmental and Economic performances of a membrane liquid desiccant air conditioning system with/without ERV. Appl Energy 116:134–148

Abdel-Salam AH, Ge G, Simonson CJ (2013) Performance analysis of a membrane liquid desiccant air-conditioning system. Energy Build 62:559–569

Stritih U, Butala V (2010) Experimental investigation of energy saving in buildings with PCM cold storage. Int J Refrig 33:1676–1683

Abdel-Salam AH, Ge G, Simonson CJ (2014) Thermo-economic performance of a solar membrane liquid desiccant air conditioning system. Sol Energy 102:56–73

Budaiwi I, Abdou A (2013) HVAC system operational strategies for reduced energy consumption in buildings with intermittent occupancy: the case of mosques. Energy Convers Manag 73:37–50

Bergero S, Chiari A (2011) On the performances of a hybrid air-conditioning system in different climatic conditions. Energy 36:5261–5273

Sullivan C (2011) Liquid desiccant dehumidification for challenging environments. Eng Syst 28(11):38

Bergero S, Chiari A (2010) Performance analysis of a liquid desiccant and membrane contactor hybrid air-conditioning system. Energy Build 42:1976–1986

Isetti C et al (2013) Three-fluid membrane contactors for improving the energy efficiency of refrigeration and air-handling systems. Int J Ambient Energy 34:181–194

Fazilati MA et al (2016) Natural induced flow due to concentration gradient in a liquid desiccant air dehumidifier. Appl Therm Eng 105:105–117

Namvar R, Pyra D, Ge G, Simonson CJ, Besant RW (2012) Transient characteristics of a liquid-to-air membrane energy exchanger (LAMEE) experimental data with correlations. Int J Heat Mass Transf 55:6682–6694

Namvar R, Ge G, Simonson CJ, Besant RW (2013) Transient heat and moisture transfer characteristics of a liquid-to-air membrane energy exchanger (LAMEE) model verification and extrapolation. Int J Heat Mass Transf 66:757–771

Namvar R, Pyra D, Ge G, Simonson CJ, Besant RW (2012) Transient characteristics of a liquid-to-air membrane energy exchanger (LAMEE): experimental data with correlations. Int J Heat Mass Transf 55:6682–6694

Afshin M, Simonson CJ, Besant RW (2010) Crystallization limits of LiCl-water and MgCl2-water salt solutions as operating liquid desiccant in the RAMEE system. ASHRAE Trans 116:494–506

Charles NT, Johnson DW (2008) The occurrence and characterization of fouling during membrane evaporative cooling. J Membr Sci 319:44–53

Lowenstein A (2008) Review of liquid desiccant technology for HVAC applications. HVAC&R Res 14(6):819–839

Conde MR (2004) Properties of aqueous solutions of lithium and calcium chlorides: formulations for use in air conditioning equipment design. Int J Therm Sci 43(4):367–382

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Fazilati, M.A., Sedaghat, A. & Alemrajabi, AA. Transient performance and temperature field of a natural convection air dehumidifier loop. Heat Mass Transfer 53, 2287–2296 (2017). https://doi.org/10.1007/s00231-017-1984-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-017-1984-9