Abstract

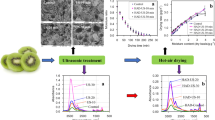

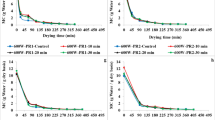

Effect of ultrasound application prior to hot air drying on drying and rehydration kinetics, rehydration ratio and microstructure of okra slices were investigated. For this purpose, the selected parameters are ultrasound pre-treatment time (10, 20 and 30 min), ultrasound amplitude (55 and 100%) and the temperature of drying air (60 and 70 °C). 5 mm thick cylindrical shaped okra slices were used in the experiments. The samples were immersed in water and ultrasonic pre-treatments were done in water with ultrasonic probe connected to an ultrasonic generator with 20 kHz frequency. Pre-treated samples were dried in a tray drier with a 0.3 m/s air velocity. Ultrasound pre-treatment affected the drying rate of the okra slices significantly. Drying time of okra slices was decreased by the application of ultrasound pre-treatment. Modified Page model found to be the most suitable model for describing the drying characteristics of okra slices. Improvements in rehydration properties of the dried samples were observed due to the ultrasound pre-treatment. The influence of the ultrasound pre-treatment on microstructure was clearly observed through scanning electron microscopy images of the dried samples. As the amplitude of ultrasound increased the changes in structure of the okra tissue increased.

Similar content being viewed by others

References

Temenouga V, Charitidis T, Avgidou M, Karayannakidis PD, Dimopoulou M, Kalogianni EP, Panayiotou C, Ritzoulis C (2016) Novel emulsifiers as a products from internal Maillard reactions in okra hydrocolloid mucilage. Food Hydrocoll 52:972–981

Ghori MU, Alba K, Smith AM, Conway BR, Kontogiorgos V (2014) Okra extracts in pharmaceucital and food applications. Food Hydrocoll 42:342–347

Dadalı G, Kılıç Apar D, Özbek B (2007) Microwave drying kinetics of okra. Dry Technol 5:917–924

Doymaz İ (2005) Drying characteristics and kinetics of okra. J Food Eng 69:275–279

Pendre NK, Nema PK, Sharma HP, Rathore SS, Kushwah SS (2012) Effect of drying temperature and slice size on quality of dried okra (Abelmoschus esculentus (L.) Moench). J Food Sci Technol 49:378–381

Akpınar EK, Biçer Y, Yıldız C (2003) Thin layer drying of red pepper. J Food Eng 59:99–104

Vega-Galvez A, Scala KD, Rodriguez K, Lemus M, Miranda M, Lopez J, Perez-Won M (2009) Effect of air drying temperature on physico-chemical properties, antioxidant capacity, colour and total phenolic content of red pepper. Food Chem 117:647–653

Garcia-Perez JV, Carcél JA, Benedito M, Mulet A (2007) Power ultrasound mass transfer enhancement in food drying. Food Bioprod Process 85:247–254

Rastogi NK (2011) Opportunities and challenges in application of ultrasound in food processing. Crit Rev Food Sci 51:705–722

De la Fuente-Blanco S, Riera-Franco de Sarabia E, Acosta-Aparicio VM, Blanco-Blanco A, Gallego-Juárez JA (2006) Food drying process by power ultrasound. Ultrasonics 44:523–527

Mulet A, Carcel JA, Sanjuan N, Bon J (2003) New food drying technologies—use of ultrasound. Food Sci Technol Int 9:215–221

Deng Y, Zhao Y (2008) Effect of pulsed vacuum and ultrasound osmopretreatments on glass transition temperature, texture, microstructure and calcium penetration of dried apples (Fuji). LWT Food Sci Technol 41:1575–1585

Topdaş EF, Başlar M, Ertugay MF (2011) Elmaların ozmotik kurutulması üzerine ultrases işleminin etkisi. Akademik Gıda 9:6–10

Azoubel PM, Baima MAM, Amorim MR (2010) Effect of ultrasound on banana cv Pacovan drying kinetics. J Food Eng 97:194–198

Fernandes FAN, Rodrigues S (2007) Ultrasound as pre-treatment for drying of fruits: dehydration of banana. J Food Eng 82:261–267

Jambrak AR, Mason TJ, Paniwyk L, Lelas V (2007) Accelarated drying of button mushrooms, Brussels sprouts and cauliflower by applying power ultrasound and its rehydration properties. J Food Eng 81:88–97

Oliviera FIP, Gallão MI, Rodrigues S, Fernandes FAN (2010) Dehydration of malay apple (Syzygium malaccense L.) using ultrasound as pre-treatment. Food Bioprocess Technol 4:610–615

Lucio-Juárez JS, Moscosa-Santillán M, González-García R, Grajales-Lagunes A, Ruiz-Cabrera MA (2013) Ultrasonic assisted pre-treatment method of enhancing mass transfer during the air-drying of Habanero Chili Pepper (Capsicum chinense). Int J Food Prop 16:867–881

Mederios RAB, Barros ZMP, Carvalho CBO, Neta EGF, Maciel MIS, Azoubel PM (2016) Influence of dual-stage sugar substitution pretreatment on drying kinetics and quality parameters of mango. LWT Food Sci Technol 67:167–173

Fernandes FAN, Gallão MI, Rodrigues S (2008) Effect of osmotic dehydration and ultrasound pre-treatment on cell structure: Melon dehydration. LWT Food Sci Technol 41:604–610

Dehghannya J, Gorbani R, Ghanbarzadeh B (2015) Effect of ultrasound-assisted osmotic dehydration pretreatment on drying kinetics and effective moisture diffusivity of Mirabelle plum. J Food Process Preser 39:2710–2717

Garcia-Perez JV, Ortuno C, Carcél JA, Perez-Munuera I (2012) Enhancement of water transport and microstructural changes induced by high-intensity ultrasound application on orange peel drying. Food Bioprocess Technol 5:2256–2265

Fernandes FAN, Oliviera FIP, Rodrigues S (2008) Use of ultrasound for dehydration of papayas. Food Bioprocess Technol 1:339–345

Dujmic F, Brncic M, Karlovic S, Bosiljkov T, Jezek D, Tripalo B, Mofardin I (2013) Ultrasound-assisted infrared drying of pear slices: textural issues. J Food Process Eng 36:397–406

Fernandes FAN, Gallão MI, Rodrigues S (2009) Effect of osmosis and ultrasound on pineapple cell tissue structure during dehydration. J Food Eng 90:186–190

Rodrigues S, Gomes MCF, Gallao MI, Fernandes FAN (2008) Effect of ultrasound-assisted osmotic dehydration on cell structure of sapotas. J Sci Food Agric 89:665–670

Garcia-Noguera J, Oliveira FIP, Weller CL, Rodrigues S, Fernandes FAN (2014) Effect of ultrasonic and osmotic dehydration pre-treatments on the colour of freeze dried strawberries. J Food Sci Technol 51:2222–2227

AOAC (1984) Official methods of analysis. Association of Official Analytical Chemists, Washington

Demiray E, Tülek Y (2012) Thin-layer drying of tomato (Lycopersicum esculentum Mill. cv. Rio Grande) slices in a convective hot air dryer. Heat Mass Trans 48:841–847

Doymaz İ (2009) An experimental study on drying of green apples. Dry Technol 27:478–485

Pehlivan D, Toğrul IT (2004) Modelling of thin layer drying kinetics of some fruits under open-air sun drying process. J Food Eng 65:413–425

Toğrul H (2006) Suitable drying model for infrared drying of carrot. J Food Eng 77:610–619

Doymaz İ (2015) Infrared drying kinetics and quality characteristics of carrot slices. J Food Process Preser 39:2738–2745

Turhan M, Sayar S, Gunasekaran S (2002) Application of Peleg model to study water absorption in chickpea during soaking. J Food Eng 53:153–159

Sobukola O (2009) Effect of pre-treatment on the drying characteristics and kinetics of okra (Abelmoschus esculetus (L.) Moench) slices. Int J Food Eng 5:234–247

Garcia-Pascual P, Sanjuan N, Melis R, Mulet A (2006) Morchella esculenta (morel) rehydration process modelling. J Food Eng 72:346–353

Acknowledgements

The authors gratefully acknowledge Pamukkale University Scientific Researches Project Unit (Project No: PAUBAP 2012FBE060) for financial support.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Rights and permissions

About this article

Cite this article

Tüfekçi, S., Özkal, S.G. Enhancement of drying and rehydration characteristics of okra by ultrasound pre-treatment application. Heat Mass Transfer 53, 2279–2286 (2017). https://doi.org/10.1007/s00231-017-1983-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-017-1983-x