Abstract

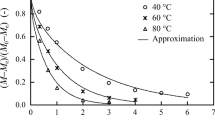

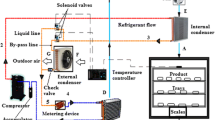

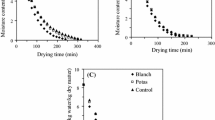

This study was intended to determine the drying and rehydration kinetics of convective and freeze dried pumpkin slices (0.5 × 3.5 × 0.5 cm). A pilot scale tray drier (at 80 ± 2 °C inlet temperature, 1 m s−1 air velocity) and freeze drier (13.33 kPa absolute pressure, condenser temperature of −48 ± 2 °C) were used for the drying experiments. Drying curves were fitted to six well-known thin layer drying models. Nonlinear regression analysis was used to evaluate the parameters of the selected models by using statistical software SPSS 16.0 (SPSS Inc., USA). For the convective and freeze drying processes of pumpkin slices, the highest R2 values, and the lowest RMSE as well as χ2 values were obtained from Page model. The effective moisture diffusivity (Deff) of the convective and freeze dried pumpkin slices were obtained from the Fick’s diffusion model, and they were found to be 2.233 × 10−7 and 3.040 × 10−9 m2s−1, respectively. Specific moisture extraction rate, moisture extraction rate, and specific energy consumption values were almost twice in freeze drying process. Depending on the results, moisture contents and water activity values of pumpkin slices were in acceptable limits for safe storage of products. The rehydration behaviour of [at 18 ± 2 and 100 ± 2 °C for 1:25, 1:50, 1:75, 1:100, and 1:125 solid:liquid ratios (w:w)] dried pumpkin slices was determined by Peleg’s model with the highest R2. The highest total soluble solid loss of pumpkin slices was observed for the rehydration experiment which performed at 1:25 solid: liquid ratio (w:w). Rehydration ratio of freeze dried slices was found 2–3 times higher than convective dried slices.

Similar content being viewed by others

References

Ratti C (2001) Hot air and freeze-drying hot-value foods: a review. J Food Eng 49:311–319

Krokida MK, Zacharias B, Maroulis ZB (2001) Structural properties of dehydrated products during rehydration. Int J Food Sci Technol 36:529–538

Marabi A, Jacobson M, Livings SJ, Saguy IS (2004) Effect of mixing and viscosity on rehydration of dry food particulates. Eur Food Res Technol 218:339–344

Sanjuan N, Simal S, Bon J, Mulet A (1999) Modelling of broccoli stems rehydration process. J Food Eng 42:27–31

Wang ZL, Finlay WH, Peppler MS, Sweeney LG (2006) Powder formation by atmospheric spray-freeze-drying. Powder Technol 170:45–52

Shofian NM, Hamid AA, Osman A, Saari N, Anwar F, Dek MSP, Hairuddin MR (2011) Effect of freeze-drying on the antioxidant compounds and antioxidant activity of selected tropical fruits. Int J Mol Sci 12:4678–4692

Zea LP, Yusof YA, Aziz MG, Ling CN, Amin NAM (2013) Compressibility and dissolution characteristics of mixed fruit tablets made from guava and pitaya fruit powders. Powder Technol 247:112–119

Que F, Mao L, Fang X, Wu T (2008) Comparison of hot air-drying and freeze-drying on the physicochemical properties and antioxidant activities of pumpkin (Cucurbita moschata Duch.) flours. Int J Food Sci Technol 43:1195–1201

Akpinar EK, Midilli A, Bicer Y (2003) Experimental investigation of drying behaviour and conditions of pumpkin slices via a cyclone-type dryer. J Sci Food Agric 83:1480–1486

Alibas I (2007) Microwave, air and combined microwave-air-drying parameters of pumpkin slices. LWT-Food Sci Technol 40:1445–1451

Garcia CC, Mauro MA, Kimura M (2007) Kinetics of osmotic dehydration and air-drying of pumpkins (Cucurbita moschata). J Food Eng 82:284–291

Perez NE, Schmalko ME (2009) Convective drying of pumpkin: influence of pretreatment and drying temperature. J Food Process Eng 32:88–103

Nawirska A, Figiel A, Kucharska AZ, Letowska AS, Biesiada A (2009) Drying kinetics and quality parameters of pumpkin slices dehydrated using different methods. J Food Eng 94:14–20

Guine RPF, Pinho S, Barroca MJ (2011) Study of the convective drying of pumpkin (Cucurbita maxima). Food Bioprod Process 89:422–428

Akintunde TYT, Ogunlakin GO (2011) Influence of drying conditions on the effective moisture diffusivity and energy requirements during the drying of pre-treated and untreated pumpkin. Energy Convers Manag 52:1107–1113

Mayor L, Moreira R, Sereno AM (2011) Shrinkage, density, porosity and shape changes during dehydration of pumpkin (Cucurbita pepo L.) fruits. J Food Eng 103:29–37

Wang J, Wang JS, Yu Y (2007) Microwave drying characteristics and dried quality of pumpkin. Int J Food Sci Technol 42:148–156

Arévalo-Pinedo A, Murr FEX (2006) Influence of pre-treatments on the drying kinetics during vacuum drying of carrot and pumpkin. J Food Eng 80:152–156

Marques LG, Prado MM, Freire JT (2009) Rehydration characteristics of freeze-dried tropical fruits. LWT Food Sci Technol 42:1232–1237

Oliveira FAR, Ilincanu L (1999) Rehydration of dried plant tissues: basic concepts and mathematical modelling. In: Oliveira FAR, Oliveira JC (eds) Processing foods. CRC Press, Boca Raton, FL, pp 201–227

Krokida MK, Kouris DM (2003) Rehydration kinetics of dehydrated products. J Food Eng 57:1–7

García-Pascual P, Sanjuá N, Bon J, Carreres JE, Mulet A (2005) Rehydration process of Boletus edulis mushroom: characteristics and modelling. J Sci Food Agric 85:1397–1404

Hernando I, Sanjuán N, Pérez-Munuera I, Mulet A (2008) Rehydration of freeze-dried and convective dried Boletus edulis mushrooms: effect on some quality parameters. J Food Sci 73(8):356–362

Noshad M, Mohebbi M, Shahidi F, Mortazavi SA (2012) Kinetic modeling of rehydration in air-dried quinces pretreated with osmotic dehydration and ultrasonic. J Food Process Preserv 36:383–392

Maskan M (2001) Drying, shrinkage and rehydration characteristics of kiwifruits during hot air and microwave drying. J Food Eng 48:177–182

Planinić M, Velić D, Tomas S, Bilić M, Bucić A (2005) Modelling of drying and rehydration of carrots using Peleg’s model. Eur Food Res Technol 221:446–451

Meda L, Ratti C (2005) Rehydration of freeze-dried strawberries at varying temperatures. J Food Process Eng 28:233–246

Atarés L, Chiralt A, Martínez CG (2009) Effect of the impregnated solute on air drying and rehydration of apple slices (ct. Granny Smith). J Food Eng 91:305–310

Marabi A, Saguy IS (2005) Viscosity and starch particle size effects on rehydration of freeze-dried carrots. J Sci Food Agric 85:700–706

Gowen AA, Abu-Ghannam N, Frias JM, Barat JM, Andres AM, Oliveira JC (2006) Comparative study of quality changes occurring on dehydration and rehydration of cooked chickpeas (Cicer Arietinum L.) subjected to combined microwave–convective and convective hot air dehydration. Food Eng Phys Prop 71(6):282–289

Balasubramanian S, Sharma R, Gupta RK, Patil RT (2011) Validation of drying models and rehydration characteristic of betel (Piper betel L.) leaves. J Food Sci Technol 8(6):685–691

Markowski M, Zielińska M (2011) Kinetics of water absorption and soluble-solid loss of hot-air-dried carrots during rehydration. Int J Food Sci Technol 46:1122–1128

Erbay Z, Icier F (2009) A review of thin layer drying of foods: theory, modeling, and experimental results. Crit Rev Food Sci 50:441–464

Bennamoun L, Kahlerras L, Michel F, Courard L, Salmon T, Fraikin L, Belhamri A, Léonard A (2013) Determination of moisture diffusivity during drying of mortar cement: experimental and modeling study. Int J Energy Environ 3(1):1–6

Chua KJ, Chou SK, Ho JC, Hawlader MNA (2002) Heat pump drying: recent developments and future trends. Dry Technol 20(8):1580–1600

Jindarat W, Rattanadecho P, Vongpradubchai S (2011) Analysis of energy consumption in microwave and convective drying process of multi-layered porous material inside a rectangular wave guide. Exp Therm Fluid Sci 35:728–737

AOAC (2000) Official methods of analysis, 17th edn. Association of Official Analytical Chemists, Gaithersburg

Lopez-malo A, Palou E, Barbosa-Canovas GV, Welti-Chanes J, Swanson BG (1998) Polyphenoloxidase activity and color changes during storage of high hydrostatic pressure treated avocado puree. Food Res Int 31(8):549–556

Peleg M (1988) An empirical model for the description of moisture sorption curves. J Food Sci 53:1216–1219

Doymaz I (2007) The kinetics of convective air-drying of pumpkin slices. J Food Eng 79:243–248

Gehrmann D, Zank J, Kempkes DI (2004) Gentle drying methods in the pharmaceutical and food industry. In: Eikevik TM (ed) Dewatering Laboratory NTNU—SINTEF. Trondheim, Norway, p 38

Quek SY, Chok NK, Swedlund P (2007) The physicochemical properties of spray- dried watermelon powders. Chem Eng Process 46:386–392

Karaman S, Toker OS, Cam M, Hayta M, Dogan M, Kayacier A (2014) Bioactive and physicochemical properties of persimmon as affected by drying methods. Dry Technol 32:258–267

Goncalves EM, Pinheiro J, Abreu M, Brandão TRS, Silva CLM (2007) Modelling the kinetics of peroxidase inactivation, colour and texture changes of pumpkin (Cucurbita maxima L.) during blanching. J Food Eng 81:693–701

Goula AM, Adamopoulos KG (2010) A new technique for spray drying orange juice concentrate. Innov Food Sci Emerg 11(2):342–351

Telis VRN, Sobral PJA (2002) Glass transitions for freeze-dried and air-dried tomato. Food Res Int 35:435–443

Sobral PJA, Telis VRN, Habitante AMQB, Sereno A (2001) Phase diagram for freeze-dried persimmon. Thermochim Acta 376(1):83–89

Khalloufi S, Ratti C (2003) Quality deterioration of freeze-dried foods as explained by their glass transition temperature and internal structure. J Food Sci 68(3):892–903

Marques LG, Ferreira MC, Freire JT (2007) Freeze-drying of acerola (Malpighia glabra L.). Chem Eng Process 46:451–457

Wang H, Zhang S, Chen G (2008) Glass transition and state diagram for fresh and freeze-dried Chinese gooseberry. J Food Eng 84:307–312

Goula AM, Adamopoulos KG (2009) Modeling the rehydration process of dried tomato. Dry Technol 27:1078–1088

Solomon W (2007) Hydration kinetics of lupin (Lupines albus) seeds. J Food Process Eng 30:119–130

Fito P, LeMaguer M, Betoret Fito PJ (2007) Advanced food process engineering to model real foods and processes: the ‘‘SAFES” methodology. J Food Eng 83:173–185

Mastrocola D, Rosa MD, Massini R (1997) Freeze-dried strawberries rehydrated in sugar solutions: mass transfers and characteristics of final products. Food Res Int 30(5):359–364

Giraldo G, Vásques R, Martín-Esparza ME, Chiralt A (2006) Rehydration kinetics and solids lixiviation of candied mango fruit as affected by sucrose concentration. J Food Eng 77:825–834

Jayaraman KS, Das Gupta DK, Babu Rao N (1990) Effect of pretreatment with salt and sucrose on the quality and stability of dehydrated cauliflower. Int J Food Sci Technol 25:47–60

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Caliskan, G., Dirim, S.N. Drying characteristics of pumpkin (Cucurbita moschata) slices in convective and freeze dryer. Heat Mass Transfer 53, 2129–2141 (2017). https://doi.org/10.1007/s00231-017-1967-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-017-1967-x