Abstract

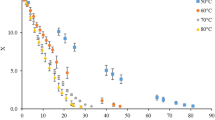

In this study, tomato slices were dried at three different drying air temperatures (35, 40 and 45 °C) and at 1 m/s air velocities by using a closed loop heat pump dryer (HPD). To explain the drying characteristics of tomato slices, ten thin-layer drying models were applied. The drying of tomato slices at each temperature occurred in falling-rate period; no constant-rate period of drying was observed. The drying rate was significantly influenced by drying temperature. The effective moisture diffusivity varied between 8.28 × 10−11 and 1.41 × 10−10 m2/s, the activation energy was found to be 43.12 kJ/mol. Besides, at the end of drying process, the highest mean specific moisture extraction ratio and coefficient of performance of HPD system were obtained as 0.324 kg/kWh and 2.71, respectively, at the highest drying air temperature (45 °C).

Similar content being viewed by others

Abbreviations

- COP hp :

-

Coefficient of performance of heat pump

- COP sys :

-

Coefficient of performance of whole system

- \(\dot{W}_{comp}\) :

-

Power consumption of compressor (kW)

- \(\dot{Q}_{cd}\) :

-

The amount of heat transferred to drying air (kW)

- \(\dot{W}_{fan }\) :

-

Power consumption of fan (kW)

- \(\dot{m}_{a}\) :

-

Mass flow rate of drying air (kg/s)

- h A :

-

Specific enthalpy of drying air at condenser outlet (kJ/kg)

- h E :

-

Specific enthalpy of drying air at condenser inlet (kJ/kg)

- SMER :

-

Specific moisture extraction ratio (kg/kWh)

- \(\dot{m}_{w}\) :

-

Mass flow rate of water extracted from product (kg/h)

- MR:

-

Moisture ratio

- Mt :

-

Moisture ratio at any time

- Mo :

-

Initial moisture ratio

- Me :

-

Equilibrium moisture ratio

- DR:

-

Drying rate

- MR exp,i :

-

Experimental dimensionless moisture ratio

- MR pre,i :

-

Predicted dimensionless moisture ratios

- N :

-

Number of observations

- z :

-

Number of constants

- D eff :

-

Effective moisture diffusivity (m2/s)

- t :

-

Time (s)

- L :

-

Half-thickness of samples (m)

- n :

-

Number of arguments and summation index

- D 0 :

-

Pre-exponential factor (m2/s)

- E a :

-

Activation energy (kJ/mol)

- R :

-

Universal gas constant (kJ/mol K)

- T :

-

Drying air temperature (K)

- un :

-

Error rates

- UF :

-

Total uncertainty

- a:

-

Air, constant in drying models

- w:

-

Water

- comp:

-

Compressor

- fan:

-

Fan

- i:

-

Inlet

- o:

-

Outlet

- hp:

-

Heat pump

- sys:

-

System

- b:

-

Constant in drying models

- c:

-

Constant in drying models

- g:

-

Coefficient in drying models, 1/s

- k:

-

Coefficient in drying models, 1/s

- n:

-

Constant in drying models

References

Abano EE, Ma H, Qu W (2012) Influence of combined microwave-vacuum drying on drying kinetics and quality of dried tomato slices. J Food Qual 35:159–168

Abuşka M, Doğan H (2010) Endüstriyel tip ısı pompalı kurutucuda çekirdeksiz üzümün kurutulması. Politeknik Dergisi 13(4):271–279

Achariyaviriya S, Sopanronnarit S, Terdyothin A (2000) Mathematical model development and simulation of heat pump fruit dryer. Dry Technol 18(1–2):479–591

Aghbashlo M, Kianmehr MH, Khani S, Ghasemi M (2009) Mathematical modeling of carrot thin-layer drying using new model. Int Agrophys 23:313–317

Aktas M, Sevik S, Doğan H, Ozturk M (2012) Fotovoltaik ve termal günes enerjili sürekli bir kurutucuda domates kurutulması. J Agric Sci 18:287–298

Aktas M, Kara MÇ (2013) Güneş Enerjisi ve Isı Pompalı Kurutucuda Dilimlenmiş Kivi Kurutulması. J Fac Eng Archit Gazi Univ 28(4):733–741

Aktas M, Ceylan I, Yılmaz S (2009) Determination of drying characteristics of apples in a heat pump and solar dryer. Desalination 239:266–275

Bagheri H, Arabhosseini A, Kianmehr MH, Chegini GR (2013) Mathematical modeling of thin layer solar drying of tomato slices. Agric Eng Int CIGR J 15:146–153

Bennamoun L, Khama R, Léonard A (2015) Convective drying of a single cherry tomato: modeling and experimental study. Food Bioprod Process 94:114–123

Ceylan I (2009) Energy analysis of PID controlled heat pump dryer. Engineering 1:188–195

Chua K, Mujumdar A, Hawlader M, Chou S, Ho J (2001) Batch drying of banana pieces-effect of stepwise change in drying air temperature on drying kinetics and product colour. Food Res Int 34(8):721–731

Colak N, Hepbaslı A (2009) A review of heat pump drying part 1-systems models and stuides. Energy Convers Manag 50:2180–2186

Crank J (1975) The mathematics of diffusion. Oxford University Press, London

Doymaz I (2007) Air drying characteristics of tomatoes. J Food Eng 78(4):1291–1297

El-Sebaii AA, Aboul-Enein S, Ramadan MRI, El-Gohary HG (2002) Empirical correlations for drying kinetics of some fruits and vegetables. Energy 27(9):845–859

Faal S, Tavakoli T, Ghobadian B (2015) Mathematical modelling of thin layer hot air drying of apricot with combined heat and power dryer. J Food Sci Technol 52:2950–2957

Fahloul D, Lahbari M, Benmoussa H, Mezdour S (2009) Effect of osmotic dehydration on the freeze drying kinetics of apricots. J Food Agric Environ 7:117–121

FAO (2014) http://faostat3.fao.org/compare/E

Falade KO, Ogunwolu OS (2014) Modeling of drying patterns of fresh and osmotically pretreated cooking banana and plantain slices. J Food Process Preserv 38:373–388

Filho OA, Strommen I (1996) The application of heat pump in drying of biomaterials. Dry Technol 14(9):2061–2090

Hasturk Sahin F, Aktas T, Orak H, Ulger P (2011) Influence of pretreatments and different drying methods on color parameters and lycopene content of dried tomato. Bulg J Agric Sci 17:867–881

Hawlader MNA, Perera CO, Tian M (2006) Properties of modified atmosphere heat pump dried foods. J Food Eng 74:392–401

Holman JP (1994) Experimental methods for engineers, 6th edn, McGraw-Hill, Singapore City

Jia X, Jolly P, Clements S (1990) Heat pump assisted continuous drying part 2: simulation results. Int J Energy Res 14:771–782

Juan W, Chong Z, Zhentao Z, Luwei Y (2013) Performance analysis of heat pump dryer to dry mushroom. Adv J Food Sci Technol 5(2):164–168

Kingsly ARP, Singh R, Goyal RK, Singh DB (2007) Thin-layer drying behavior of organically produced tomato. Am J Food Technol 2:71–78

Midilli A, Kucuk H, Yapar Z (2002) A new model for single layer drying. Dry Technol 20:1503–1513

Pal US, Khan MK, Mohanty SN (2008) Heat pump drying of green sweet pepper. Dry Technol 26:1584–1590

Phani KA, Greg JS (2005) Re-circulating heat pump assisted continuous bed drying and energy analysis. Int J Energy Res 29:961–972

Ponkham K, Meeso N, Soponronnarit S, Siriamornpun S (2012) Modeling of combined far-infrared radiation and air drying of a ring shaped-pineapple with/without shrinkage. Food Bioprod Proces 90:155–164

Prasertsan S, Saen-Saby P (1998) Heat pump drying of agricultural material. Dry Technol 16(1–2):235–250

Purkayastha MD, Nath A, Deka BC, Mahanta CL (2013) Thin layer drying of tomato slices. J Food Sci Technol 50(4):642–653

Queiroz R, Gabas AL, Telis VRN (2004) Drying kinetics of tomato by using electric resistance and heat pump dryers. Dry Technol 22(7):1603–1620

Sacilik K, Keskin R, Elicin AK (2006) Mathematical modeling of solar tunnel drying of thin layer organic tomato. J Food Eng 73:231–238

Soponronnarit S, Nathakaranakule A, Wetchacama S, Swasdisevi T, Rukprang P (1998) Fruit drying using heat pump. RERIC Int Energy J 20:38–53

Strommen I, Kramer K (1994) New applications of heat pumps in drying processes. Dry Technol 12(4):889–901

Teeboonma U, Tiansuwan J, Soponronnarit S (2003) Optimization of heat pump fruit dryers. J Food Eng 59:369–377

Tosun S (2009) Bazı Tarımsal Ürünler İçin Isı Pompalı Bir Kurutucunun Geliştirilmesi ve Termodinamik Analizi. Doktora Tezi Ege Üniversitesi Fen Bilimleri Enstitüsü

Yun-Hong L, Shuai M, Jian-Ye W, Jian-Xue L (2014) Drying and quality characteristics of flos lonicerae in modified atmosphere with heat pump system. J Food Process Eng 37:37–45

Zanoni B, Peri C, Nani R, Lavell V (1998) Oxidative heat damage of tomato halves as affected by drying. Food Res Int 31(5):395–401

Zogzas NP, Maroulis ZB, Marinos-Kouris D (1996) Moisture diffusivity data compilation in foodstuffs. Dry Technol 14:2225–2253

Acknowledgements

The authors wish to extend their thanks to the Yalova University Scientific Research Projects Coordination Unit for their support of Project No. 2013/BAP/082 entitled “Investigation Regarding the Quality and Energy Efficiency of the Use of the Heat Pump in The Drying of Agricultural Products” and to the Laboratory of the Atatürk Horticultural Research Institute which was opened for their use.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Coşkun, S., Doymaz, İ., Tunçkal, C. et al. Investigation of drying kinetics of tomato slices dried by using a closed loop heat pump dryer. Heat Mass Transfer 53, 1863–1871 (2017). https://doi.org/10.1007/s00231-016-1946-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-016-1946-7