Abstract

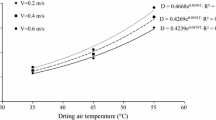

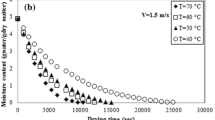

An accurate prediction of moisture transfer parameters is very important for efficient mass transfer analysis, accurate modelling of drying process, and better designing of new dryers and optimization of existing drying process. The present study aimed to investigate the influence of temperature (e.g., 55, 65 and 75 °C) and chamber pressure (e.g., 0.1, 3, 7, 10, 13 and 17 kPa) on effective diffusivity and convective mass transfer coefficient of celeriac slices during vacuum drying. The obtained Biot number indicated that the moisture transfer in the celeriac slices was controlled by both internal and external resistance. The effective diffusivity obtained to be in the ranges of 7.5231 × 10−10–3.8015 × 10−9 m2 s−1. The results showed that the diffusivity increased with increasing temperature and decreasing pressure. The mass transfer coefficient values varied from 4.6789 × 10−7 to 1.0059 × 10−6 m s−1, and any increment in drying temperature and pressure caused an increment in the coefficient.

Similar content being viewed by others

Abbreviations

- Bi :

-

Biot number (–)

- D :

-

Effective moisture diffusivity (m2 s−1)

- G :

-

Lag factor (–)

- k :

-

Moisture transfer coefficient (m s−1)

- L :

-

Thickness of samples (m)

- M :

-

Instantaneous moisture content (gwater/gdry matter)

- M e :

-

Equilibrium moisture content (gwater/gdry matter)

- M 0 :

-

Initial moisture content (gwater/gdry matter)

- M s :

-

Moisture content at surface of sample (gwater/gdry matter)

- MR :

-

Moisture ratio (–)

- S :

-

Drying coefficient (s−1)

- t :

-

Drying time (s)

- µ 1 :

-

The first root of the transcendental characteristic equation (–)

References

Beigi M (2015) Influence of drying air parameters on mass transfer characteristics of apple slices. Heat Mass Transf. doi:10.1007/s00231-015-1646-8

Mujumdar SA (2014) Hand book of industrial drying, 4th edn. CRC Press, Boca Raton

Wu L, Orikasa T, Ogawa Y, Tagawa A (2007) Vacuum drying characteristics of eggplants. J Food Eng 83:422–429

Bazyma LA, Guskov VP, Basteev AV, Lyashenko AM, Lyakhno V, Kutuvoy VA (2006) The investigation of low temperature vacuum drying processes of agricultural materials. J Food Eng 74:410–415

Jena S, Das H (2007) Modelling for vacuum drying characteristics of coconut presscake. J Food Eng 79:92–99

Alibas I (2012) Determination of vacuum and air drying characteristics of celeriac slices. J Biol Environ Sci 6:1–13

Zakipour E, Hamidi Z (2011) Vacuum drying characteristics of some vegetables. Iran J Chem Chem Eng 30:97–105

Mrkic V, Ukrainczyk M, Tripalo B (2007) Applicability of moisture transfer Bi–Di correlation for convective drying of broccoli. J Food Eng 79:640–646

Kim D, Son G, Kim S (2016) Numerical analysis of convective drying of a moist object with combined internal and external heat and mass transfer. J Mech Sci Technol 30:733–740

Saravacos GS, Maroulis ZB (2001) Transport properties of food. Marcel Dekker Press, New York

Tiwari GN, Kumar S, Prakash O (2004) Evaluation of convective mass transfer coefficient during drying of jiggery. J Food Eng 63:219–227

Babalis SJ, Belessiotis VG (2004) Influence of the drying conditions on the drying constants and moisture diffusivity during the thin-layer drying of figs. J Food Eng 65:449–458

Dak M, Pareek NK (2014) Effective moisture diffusivity of pomegranate arils undergoing microwave-vacuum drying. J Food Eng 122:117–121

Torki-Harchegani M, Ghanbarian D, Sadeghi M (2015) Estimation of whole lemon mass transfer parameters during hot air drying using different modelling methods. Heat Mass Transf 51:1121–1129

Dincer I, Dost S (1995) An analytical model for moisture diffusion in solid objects during drying. Dry Technol 13:425–435

Dincer I, Dost S (1996) A modelling study for moisture diffusivities and moisture transfer coefficients in drying of solid objects. Int J Energy Res 20:531–539

Mwithiga G, Olwal JO (2005) The drying kinetics of kale (Brassica oleracea) in a convective hot air dryer. J Food Eng 71:373–378

Evin D (2012) Thin layer drying kinetics of Gundelia tournefortii L. Food Bioprod Process 90:323–332

Akhondi E, Kazemi A, Maghsoodi V (2011) Determination of a suitable thin layer drying curve model for saffron (Crocus sativus L) stigmas in an infrared dryer. Sci Iran 18:1397–1401

Kaya A, Aydin O, Dincer I (2010) Comparison of experimental data with results of some drying models for regularly shaped products. Heat Mass Transf 46:555–562

Kaya A, Aydin O, Demirtas C (2007) Drying kinetics of red delicious apple. Biosyst Eng 96:517–524

Celma AR, Rojas S, Lopez-Rodríguez F (2008) Mathematical modeling of thin-layer infrared drying of wet olive husk. Chem Eng Process 47:1810–1818

Evin D (2011) Microwave drying and moisture diffusivity of white mulberry: experimental and mathematical modeling. J Mech Sci Technol 25:2711–2718

Mortezapour H, Ghobadian B, Khoshtaghaza MH, Minaei S (2014) Drying kinetics and quality characteristics of saffron dried with a heat pump assisted hybrid photovoltaic-thermal solar dryer. J Agric Sci Technol 16:33–45

Péré C, Rodier E (2002) Microwave vacuum drying of porous media: experimental study and qualitative considerations of internal transfers. Chem Eng Process 41:427–436

Methakhup S, Chiewchan N, Devahastin S (2005) Effects of drying methods and conditions on drying kinetics and quality of Indian gooseberry flake. LWT Food Sci Technol 38:579–587

Dincer I (1998) Moisture transfer analysis during drying of slab woods. Heat Mass Transf 34:317–320

Sadeghi M, Mirzabeigi Kesbi O, Mireei SA (2013) Mass transfer characteristics during convective, microwave and combined microwave-convective drying of lemon slices. J Sci Food Agric 93:471–478

Maskan A, Kaya S, Makan M (2002) Hot air and sun drying of grape leather (pestil). J Food Eng 54:81–88

Duc LA, Han JW, Keum DH (2011) Thin layer drying characteristics of rapeseed (Brassica napus L.). J Stored Prod Res 47:32–38

Doymaz I, Ismail O (2011) Drying characteristics of sweet cherry. Food Bioprod Process 89:31–38

Akpinar EK (2008) Mathematical modelling and experimental investigation on sun and solar drying of white mulberry. J Mech Sci Technol 22:1544–1553

Torki-Harchegani M, Ghanbarian D, Ghasemi Pirbalouti A, Sadeghi M (2016) Dehydration behaviour, mathematical modelling, energy efficiency and essential oil yield of peppermint leaves undergoing microwave and hot air treatments. Renew Sustain Energy Rev 58:407–418

Drouzas AE, Tsami E, Saravacos GD (1999) Microwave/vacuum drying of model fruit gel. J Food Eng 39:117–122

Arévalo-Pinedo A, Murr FEX (2006) Kinetics of vacuum drying of pumpkin (Cucurbita maxima): modeling with shrinkage. J Food Eng 76:562–567

Liu X, Hou H, Chen J (2013) Applicability of moisture transfer parameters estimated by correlation between Biot number and lag factor (Bi–G correlation) for convective drying of eggplant slices. Heat Mass Transf 49:1595–1601

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Beigi, M. Mass transfer parameters of celeriac during vacuum drying. Heat Mass Transfer 53, 1327–1334 (2017). https://doi.org/10.1007/s00231-016-1912-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-016-1912-4