Abstract

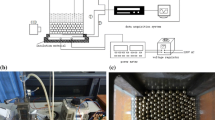

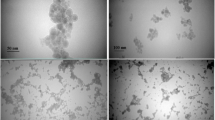

Nucleate pool boiling with porous media made of perforated copper beads as the enhanced structure is conducted in saturated, deionized and degassed water. Data are taken at an atmospheric pressure (saturation temperature of 100 °C) and at heat fluxes from 4500 to 72,300 W/m2 while increasing the heat flux. The bead-packed structure is heated on the bottom. The layer of loose particles on the heated surface is free to move under the action of bulk liquid convection and vapor nucleation. The effects of the weight (number), size and layers of the free particles are experimentally explored using copper particles for different copper bead diameters which were 2, 3, 4 and 5 mm. The boiling enhancement is closely related to the particle weight, size and layers, and the heat flux applied. The results show that free particles are presented to have a distinct advantage in boiling heat transfer, resulting in an average increase in the heat transfer coefficient of 126 % relative to the flat plate without particles. In order to obtain insight into the fluid boiling phenomena, flow visualization is also made to observe the detailed fluid boiling characteristics of the copper particles present. The visualizations show that bubble nucleation preferentially occurs at the narrow corner cavities formed between the free particles and the heated surface.

Similar content being viewed by others

Abbreviations

- A :

-

Heat transfer surface area based on the back side of the heater foil [m2]

- D e :

-

Mean pore diameter (hydraulic diameter) [m]

- D i :

-

Inner diameter of copper bead [m]

- D p :

-

Outer diameter of copper bead [m]

- E :

-

Electrical voltage [V]

- h :

-

Heat transfer coefficient [W/m2K]

- h a :

-

Heat transfer coefficient for the container with particle [W/m2K]

- h o :

-

Heat transfer coefficient for the container without particle [W/m2K]

- I :

-

Electrical current [A]

- K p :

-

Permeability [m2]

- m c :

-

Mass of copper beads [g]

- m w :

-

Mass of water [g]

- q :

-

Heat flux [W/m2]

- R h :

-

Hydraulic radius [m]

- S p :

-

Surface area of packing particle [m2]

- T :

-

Temperature [K]

- T w :

-

Average wall temperature [K]

- T s :

-

Saturation temperature [K]

- ΔT :

-

Average wall superheat (=T w − T s ) [K]

- V p :

-

Volume of packing particle [m3]

- ɛ :

-

Porosity of the tube within dispersed-copper porous inserts

References

Bankoff SG (1985) Entrapment of gas in the spreading of a liquid over a rough surface. AIChE J 4:24–26

Kim DE, Yu DI, Jerngc DW, Kimd MH, Ahn HS (2015) Review of boiling heat transfer enhancement on micro/nanostructured surfaces. Exp Thermal Fluid Sci 66:173–196

Bergles AE, Webb RL (1980) Bibliography on augmentation of convective heat and mass transfer. Previews Heat Mass Transf 6:292–314

J. Fujikaka (1980) Heat transfer tube for use in boiling type heat exchangers and method of producing the same. US Patent 4,216,826

Arshad J, Thome JR (1983) Enhanced boiling surface heat transfer mechanism mixture boiling. Proc ASME-JSME Therm Eng Jt Conf 1:191–197

Nowell RM, Bhavnani SH, Jaeger RC (1995) Effect of channel width on pool boiling from a microconfigured heat sink. IEEE Trans Compon Packaging Manuf Technol A 18:534–539

Wen MY, Hsieh SS (1994) Evaporative heat transfer and enhancement performance of rib-roughened tube annuli with refrigerant 114. Int J Heat Mass Transf 37:425–436

Wang CH, Dhir VK (1993) On the gas entrapment and nucleation site density during pool boiling of saturated water. Trans ASME J Heat Transf 115:670–679

Yang Y, Ji X, Xu J (2010) Effect of inclination angle on the pool boiling heat transfer of ultra-light copper foams. Heat Mass Transf 46:695–706

Wang CH (1992) Experimental and analytical study of the effects of wettability on nucleation site density during pool boiling. Ph D Dissertation, University of California, Los Angeles

Ayub ZH, Bergles AE (1978) Pool boiling from GEWA surfaces in water and R-113. Heat Mass Transf 21:209–219

Arai N, Fukushima T, Arai A, Nakajima T, Fujie K, Nakayama Y (1977) Heat transfer tubes enhancing boiling and condensation in heat exchangers of a refrigerating machine. ASHRAE Trans 83(1977):58–70

Memory SB, Chilman SV, Marto PJ (1994) Nucleate pool boiling of a TURBO-B bundle in R-113. J Heat Transfer 116:670–678

Nakayama W, Daikoku T, Kuwahara H, Nakajima T (1980) Dynamic model of enhanced boiling heat transfer on porous surfaces, Part 1: experimental investigation and Part 2: analytical modeling. ASME J Heat Transf 102:445–456

Echigo R (1982) Effective energy conversion method between gas enthalpy and thermal radiation and application to industrial furnaces. Heat Transf 6:361–366

Rao SM, Balakrishnan AR (1997) Analysis of pool boiling heat transfer over porous surfaces. Heat Mass Transf 32:463–469

Yang Y, Ji X, Xu J (2010) Pool boiling heat transfer on copper foam covers with water as working fluid. Int J Thermal Sci 49:1227–1237

Park KJ, Jung D (2007) Enhancement of nucleate boiling heat transfer using carbon nanotubes. Int J Heat Transf 50:4499–4502

Wen D, Ding Y (2005) Experimental investigation into the pool boiling heat transfer of aqueous based γ-alumina nanofluids. J Nanopart Res 7:265–274

White SB, Shih AJ, Pipe KP (2010) Effects of nanoparticle layering on nanofluid and base fluid pool boiling heat transfer from a horizontal surface under atmospheric pressure. J Appl Phys 107:114302

Vassallo P, Kumar R, D’Amico S (2004) Pool boiling heat transfer experiments in silica-water nano-fluids. Int J Heat Transf 47:407–411

Jung J-Y, Kim H, Kim MH (2013) Effect of ionic additive on pool boiling critical heat flux of titania/water nanofluids. Heat Mass Transf 49:1–10

Hegde RN, Rao SS, Reddy RP (2012) Boiling induced nanoparticle coating and its effect on pool boiling heat transfer on a vertical cylindrical surface using CuO nanofluids. Heat Mass Transf 48:1549–1557

Kshirsagar JM, Shrivastava R (2015) Review of the influence of nanoparticles on thermal conductivity, nucleate pool boiling and critical heat flux. Heat Mass Transf 51:381–398

Niu G, Li J (2015) Comparative studies of pool boiling heat transfer with nano-fluids on porous surface. Heat Mass transf 51:1769–1777

Huitink D, Ontiveros EED, Hassan Y (2012) The bubble fossil record: insight into boiling nucleation using nanofluid pool-boiling. Heat Mass Transf 48:267–274

Thiagarajan SJ, Yang R, King C, Narumanchi S (2015) Bubble dynamics and nucleate pool boiling heat transfer on microporous copper surfaces. Int J Heat Mass Transf 89:1297–1315

Kim TY, Weibei JA, Garimella SV (2014) A free-particles-based technique for boiling heat transfer enhancement in a wetting liquid. Int J Heat Mass Transf 71:808–817

Kim TY, Garimella SV (2014) Investigation of boiling heat transfer in water using a free-particles-based enhancement technique. Int J Heat Mass Transf 71:818–828

Wang Z, Peng XF, Ochterbeck JM (2004) Dynamic bubble behavior during boiling in bead-packed structures. Int J Heat Mass Transf 47:4771–4783

Zhou L, Wang Z, Du X, Yang Y (2015) Boiling characteristics of water and self-rewetting fluids in packed bed of spherical glass beads. Exp Thermal Fluid Sci 68:537–544

Scheidegger E (1963) The physical of flow through porous media. University of Toronto Press, Toronto, p 10

Turpin JL, Huntington RL (1967) Prediction of pressure drop for two-phase, two-component concurrent flow in packed beds. AIChE J 13:1196–1202

Hwang GJ, Chao CH (1994) Heat-transfer measurements and analysis for sintered channels. Trans ASME 116:456–464

Moffat RJ (1988) Describing the uncertainties in experimental results. Exp Therm Fluid Sci 1:3–17

Wen MY, Ho CY (2003) Pool boiling heat transfer of deionized and degassed water in vertical/horizontal V-shaped geometries. Heat Mass Transf 39:729–736

Acknowledgments

The study was supported by the National Science Council of the Republic of China through Grant No. NSC102-2221-E-230-013.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wen, MY., Jang, K.J. & Ho, CY. Pool boiling heat transfer of deionized and degassed water in packed-perforated copper beads. Heat Mass Transfer 52, 2447–2457 (2016). https://doi.org/10.1007/s00231-016-1756-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-016-1756-y