Abstract

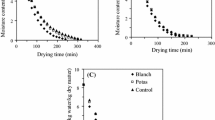

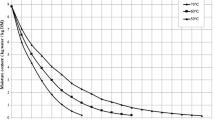

In the present work, the effects of some parametric values on convective heat transfer coefficients and the thin layer drying process of ginger slices were investigated. Drying was done in the laboratory by using cyclone type convective dryer. The drying air temperature was varied as 40, 50, 60 and 70 °C and the air velocity is 0.8, 1.5 and 3 m/s. All drying experiments had only falling rate period. The drying data were fitted to the twelve mathematical models and performance of these models was investigated by comparing the determination of coefficient (R 2), reduced Chi-square (χ 2) and root mean square error between the observed and predicted moisture ratios. The effective moisture diffusivity and activation energy were calculated using an infinite series solution of Fick’s diffusion equation. The average effective moisture diffusivity values and activation energy values varied from 2.807 × 10−10 to 6.977 × 10−10 m2/s and 19.313–22.722 kJ/mol over the drying air temperature and velocity range, respectively. Experimental data was used to evaluate the values of constants in Nusselt number expression by using linear regression analysis and consequently, convective heat transfer coefficients were determined in forced convection mode. Convective heat transfer coefficient of ginger slices showed changes in ranges 0.33–2.11 W/m2 °C.

Similar content being viewed by others

Abbreviations

- a, b, c, g, h, n :

-

Empirical constants in the drying models

- A t :

-

Area of tray (m2)

- C :

-

Constant

- C v :

-

Specific heat of humid air (J/kg °C)

- D eff :

-

Effective diffusivity (m2/s)

- D 0 :

-

Constant in Arrhenius equation (m2/s)

- E a :

-

Activation energy (kJ/mol)

- h c :

-

Convective heat transfer coefficient (W/m2 °C)

- k, k o , k 1 :

-

Empirical coefficients in the drying models (s−1)

- K v :

-

Thermal conductivity of humid air (W/m °C)

- K :

-

Slope

- L :

-

Slab thickness (m)

- \( \dot{m}_{ev} \) :

-

Moisture evaporated (kg)

- M :

-

Moisture content (dry basis)

- M e :

-

Moisture content in equilibrium state (dry basis)

- M o :

-

Moisture content at t = 0 (dry basis)

- M t :

-

Moisture content at t (dry basis)

- MR :

-

Moisture ratio (dimensionless)

- MR exp :

-

Experimental moisture ratio (dimensionless)

- MR pre :

-

Predicted moisture ratio (dimensionless)

- n :

-

Number constants, constant

- N :

-

Number of observations

- Nu :

-

Nusselt number (Nu = h c X/K v )

- Pr :

-

Prandtl number (Pr = μ v C v /K v )

- P(T):

-

Partial vapour pressure at temperature T (N/m2)

- \( \dot{Q}_{e} \) :

-

Rate of heat utilized to evaporate moisture (J/m2 s)

- r :

-

Diffusion path (m)

- R :

-

Gas consant (kJ/mol K)

- R 2 :

-

Determination coefficient

- Re :

-

Reynolds number (Re = ρvvd/μv)

- RMSE :

-

Root mean square error

- t :

-

Time (sec, h, min)

- T :

-

Temperature (°C)

- T c :

-

Product temperature (°C)

- T e :

-

Exit air temperature (°C)

- T i :

-

Average of product and humid air temperature (°C)

- X :

-

Characteristic dimension (m)

- Β :

-

Coefficient of volumetric expansion (1/°C)

- γ:

-

Relative humidity (°)

- λ:

-

Latent heat of vaporization (J/kg)

- \( \mu_{v} \) :

-

Dynamic viscosity of humid air (kg/m s)

- \( \rho_{v} \) :

-

Density of humid air (kg/m3)

- χ 2 :

-

Chi-square

References

Schweiggert U, Hofmann S, Reichel M, Schieber A, Carle R (2008) Enzyme-assisted liquefaction of ginger rhizomes (Zingiber officinale Rosc.) for the production of spray-dried and paste-like ginger condiments. J Food Eng 84:28–38

Phoungchandang S, Saentaweesuk S (2011) Effect of two stage, tray and heat pump assisted-dehumidified drying on drying characteristics and qualities of dried ginger. Food Bioprod Process 89:429–437

Sahin AZ, Dincer I (2005) Prediction of drying times for irregular shaped multidimensional moist solids. J Food Eng 71:119–126

Doymaz I (2012) Evaluation of some thin-layer drying models of persimmon slices (Diospyros kaki L.). Energy Convers Manag 56:199–205

McMinn WAM (2006) Thin-layer modeling of the convective, microwave, microwave-convective and microwave-vacuum drying of lactose powder. J Food Eng 72:113–123

Thompson TL, Peart RM, Foster GH (1968) Mathematical simulation of corn drying—a new model. Trans ASAE 12(4):582–586

Akpinar EK (2004) Experimental determination of convective heat transfer coefficient of some agricultural product in forced convection drying. Int Commun Heat Mass Transf 31(4):585–595

Eze JI, Agbo K (2011) Comparative studies of sun and solar drying of peeled and unpeeled ginger. Am J Sci Ind Res 2(2):136–143

Prasad J, Vijay VK (2005) Experimental studies on drying of Zingiber officinale, Curcuma longa l. and Tinospora cordifolia in solar-biomass hybrid drier. Renew Energy 30:2097–2109

Thorat ID, Mohapatra D, Sutar RF, Kapdi SS, Jagtap DD (2010) Mathematical modeling and experimental study on thin-layer vacuum drying of ginger (Zingiber officinale R.) slices. Food Bioprocess Technol. doi:10.1007/s11947-010-0429-y

Phoungchandang S, Nongsang S, Sanchai P (2009) The development of ginger drying using tray drying, heat pump–dehumidified drying, and mixed-mode solar drying. Dry Technol 27:1123–1131

Alakalı J, Irtwange SV, Satimehin A (2009) Moisture adsorption characteristics of ginger slices. Cienc Tecnol Aliment 29(1):155–164

Parlak N (2014) Fluidized bed drying characteristics and modeling of ginger (Zingiber officinale) slices. Heat Mass Transfer 51:1085–1095 (2015)

Ganesapillai M, Miranda LR, Reddy T, Bruno M, Singh A (2011) Modeling, characterization, and evaluation of efficiency and drying indices for microwave drying of Zingiber officinale and curcuma manga. Asia Pac J Chem Eng 6:912–920

Jayashree E, Visvanthan R (2013) Studies on thin layer drying characteristics of ginger (Zingiber officinale) in a mechanical tray drier journal of plantation crops. J Spices Aromat Crops 41(1):86–90

Afolabi JT, Tunde-Akintunde TY, Oyelade OJ (2014) Influence of drying conditions on the effective moisture diffusivity and energy requirements of ginger slices. J Food Res 3(5):103–112

Akpinar EK (2002) The development of a cyclone type dryer for agricultural products. PhD Thesis, Firat University, Elazig, Turkey

Akpinar E, Midilli A, Bicer Y (2003) Single layer drying behavior of potato slices in a convective cyclone dryer and mathematical modeling. Energy Convers Manag 44:1689–1705

Mujumdar AS (1987) Handbook of industrial drying. Marcel Dekker, New York

Diamante LM, Munro PA (1993) Mathematical modelling of thin layer solar drying of sweet potato slices. Sol Energy 51:271–276

Overhults DG, White HE, Hamilton HE, Ross IJ (1973) Drying soybeans with heated air. Trans ASAE 16:112–113

Zhang Q, Litchfield JB (1991) An optimization of intermittent corn drying in a laboratory scale thin layer dryer. Dry Technol 9:383–395

Yaldız O, Ertekin C (2001) Thin layer solar drying of some vegetables. Dry Technol 19:583–596

Henderson SM (1974) Progress in developing the thin layer drying equation. Trans ASAE 17:1167–1172

Sharaf-Eldeen YI, Blaisdell JL, Hamdy MY (1980) A model for ear corn drying. Trans ASAE 23:1261–1271

Wang CY, Singh RP (1978) A single layer drying equation for rough rice. ASAE paper no: 3001

Karathanos VT (1999) Determination of water content of dried fruits by drying kinetics. J Food Eng 39:337–344

Verma LR, Bucklin RA, Endan JB, Wratten FT (1985) Effects of drying air parameters on rice drying models. Trans ASAE 28:296–301

Midilli A, Kucuk H, Yapar Z (2002) A new model for single layer drying. Dry Technol 20(7):1503–1513

Akpinar EK (2006) Determination of suitable thin layer drying curve model for some vegetables and fruits. J Food Eng 73(1):75–84

Günhan T, Demir V, Hancioglu E, Hepbasli A (2005) Mathematical modelling of drying of bay leaves. Energy Convers Manag 46(11–12):1667–1679

Crank J (1975) The mathematics of diffusion. Clarendon press, Oxford

Akpinar EK, Toraman S (2013) Estimation of the moisture diffusivity and activation energy in thin layer drying of ginger slices. World Acad Sci Eng Technol 78:2013-06-27

Doymaz I, Ismail O (2011) Drying characteristics of sweet cherry. Food Bioprod Process 89:31–38

Goyal RK, Tiwari GN (1998) Heat and mass transfer relations for crop drying. Dry Technol 16(8):1741–1754

Jain D, Tiwari GN (2004) Effect of greenhouse on crop drying under natural and forced convection-I: evaluation of convective mass transfer coefficient. Energy Convers Manag 45:765–783

Anwar SI, Tiwari GN (2001) Convective heat transfer coefficient of crop in forced convection drying—an experimental study. Energy Convers Manag 42:1687–1698

Van Arsdel WB, Copley MJ, Margan AJ (1973) Food Dehydration. AVI Publishing Company, Westport

Belghit A, Kouhila M, Boutaleb BC (1999) Experimental study of drying kinetics of sage in a drying tunnel working in forced convection. Rev Energ Ren 2:17–26

Ndukwu MC (2009) Effect of drying temperature and drying air velocity on the drying rate and drying constant of cocoa bean. Agric Eng Int CIGR Ejournal XI:1091

Acknowledgments

Authors thank Firat University Research Foundation (FUBAP) for financial support, under Project Number 943.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Akpinar, E.K., Toraman, S. Determination of drying kinetics and convective heat transfer coefficients of ginger slices. Heat Mass Transfer 52, 2271–2281 (2016). https://doi.org/10.1007/s00231-015-1729-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-015-1729-6