Abstract

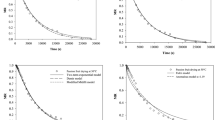

Several studies have taken into account the volume change of foods that undergo hydration or drying. However, the simplest boundary condition at the surface is usually considered to facilitate the solution of variable volume models. This paper presents a model of moisture diffusion in soybean grains that considers the volume change of these grains when absorbing water and also the dependence of diffusivity on moisture content. The boundary condition of equality of diffusive and convective flows on the surface was used and compared with two other approaches commonly found in the literature of grain hydration. This boundary condition was also applied to the case of constant volume of the grains and it was concluded that there are significant differences when the change in volume is taken into account. An analysis of the diffusion coefficients determined as functions of moisture content, temperature, and hydration time is presented for the best model.

Similar content being viewed by others

Abbreviations

- D:

-

Diffusion coefficient (m2/s)

- Deff :

-

Effective diffusion coefficient (m2/s)

- \({\text{D}}_{\text{eff}}^{*}\) :

-

Effective diffusion coefficient with respect to radius and time (m2/s)

- D0 :

-

Pre-exponential factor (m2/s)

- DPFE:

-

Distributed parameters flux equality

- DPXeq :

-

Distributed parameters Xeq

- i:

-

Index of summation (dimensionless)

- k1 :

-

Exponential factor (kgds/kgwater)

- KC :

-

Mass transfer coefficient (kg/m2 s)

- N:

-

Divisions in the radial coordinate (dimensionless)

- a0–a8 :

-

Correlation coefficient

- r:

-

Radial coordinate (m)

- R:

-

Grain radius (m)

- Rp :

-

Grain radius as a function of time (m)

- t:

-

Time (s)

- teq :

-

Equilibrium time (s)

- T:

-

Temperature (°C)

- X:

-

Moisture content (kgwater/kgds)

- Xm :

-

Average moisture content calculated by the models (kgwater/kgds)

- Xeq :

-

Equilibrium moisture content (kgwater/kgds)

- Xexp :

-

Experimental moisture content (kgwater/kgds)

- Xmax :

-

Maximum moisture content (kgwater/kgds)

- X0 :

-

Initial moisture content (kgwater/kgds)

- Xs :

-

Moisture content at the surface of the grain (kgwater/kgds)

- β:

-

Saturation rate (s−1)

- δr:

-

Radius increment (m)

- ρDS :

-

Density of dry solid (kg/m3)

- ϕ:

-

Squared residuals (kg 2water /kg 2ds )

- ϕm :

-

Average squared residuals (kg 2water /kg 2ds )

References

Crank J (1975) The mathematics of diffusion, 2nd edn. Oxford University Press, London

Coutinho MR, Omoto ES, Andrade CMG, Jorge LMM (2005) Modeling and validation of soya bean hydration. Ciênc Tecnol Aliment 25(3):603–610

Coutinho MR, Conceição WAS, Omoto ES, Andrade CMG, Jorge LMM (2007) New model of lumped parameters applied to grain hydration. Ciênc Tecnol Aliment 27(3):451–455

Gekas V, Lamberg I (1991) Determination of diffusion coefficients in volume-changing systems—application in the case of potato drying. J Food Eng 14:317–326

Nicolin DJ, Coutinho MR, Andrade CMG, Jorge LMM (2012) Hsu model analysis considering grain volume variation during soybean hydration. J Food Eng 111(3):496–504

Hsu KH (1983) A diffusion model with a concentration-dependent diffusion coefficient for describing water movement in legumes during soaking. J Food Sci 48(2):618–622

Rahman N, Kumar S (2011) Evaluation of moisture diffusion coefficient of cylindrical bodies considering shrinkage during natural convection drying. Int J Food Eng 7(1):article 4

Del Nobile MA, Buonocore GG, Panizza A, Gambacorta G (2003) Modeling the spaghetti hydration kinetics during cooking and overcooking. J Food Sci 68(4):1316–1323

Simal S, Mulet A, Catalá PJ, Cañellas J, Rosselló C (1996) Moving boundary model for simulating moisture movement in grapes. J Food Sci 61(1):157–160

Yüzgeç U, Türker M, Becerrikli Y (2008) Modelling spatial distributions of moisture and quality during drying of granular baker’s yeast. Can J Chem Eng 86:725–738

Sayar S, Turhan M, Gunasekaran S (2001) Analysis of chickpea soaking by simultaneous water transfer and water–starch reaction. J Food Eng 50(2):91–98

Lin SH (1993) Water uptake and gelatinization of white rice. Lebensmittel-Wissenschaft und – Technologie 26(3):276–278

Martinez-Navarrete N, Chiralt A (1999) Water diffusivity and mechanical changes during hazelnut hydration. Food Res Int 32(6):447–452

Gowen A, Abu-Ghannam N, Frias J, Oliveira J (2007) Influence of pre-blanching on the water absorption kinetics of soybeans. J Food Eng 78:965–971

Aguerre RJ, Tolaba M, Suarez C (2008) Modeling volume changes in food drying and hydration. Lat Am Appl Res 38:345–349

Coutinho MR, Omoto ES, Conceição WAS, Andrade CMG, Jorge LMM (2009) Modeling of the soybean grains hydration by a distributed parameters approach. Int J Food Eng 5(3):article 11

Coutinho MR, Omoto ES, Conceição WAS, Andrade CMG, Jorge LMM (2010a) Evaluation of two mathematical models applied to soybean hydration. Int J Food Eng 6(6):article 7

Engels C, Hendrickx M, De Samblanx S, De Gryze I, Tobback P (1986) Modelling water diffusion during long-grain rice soaking. J Food Eng 5(1):55–73

Coutinho MR, Conceição WAS, Paraíso PR, Andrade CMG, Omoto ES, Jorge RMM, Maciel Filho R, Jorge LMM (2010) Application of the Hsu model to soybean grain hydration. Ciênc Tecnol Aliment 30(1):19–29

Nicolin DJ, Coutinho MR, Andrade CMG, Jorge LMM (2013) Soybean hydration: investigation of distributed parameter models with respect to surface boundary conditions. Chem Eng Commun 200(7):959–976

Coutinho MR (2006) Modeling, simulation and analysis of the hydration of soy beans. Thesis (Doctorate in Chemical Engineering)—State University of Maringá, Brazil, 200 p

Instituto Adolfo Lutz (1985) Normas Analíticas do Instituto Adolfo Lutz, vol 1, 3rd edn. Instituto Adolfo Lutz, São Paulo

Yang WY, Cao W, Chung T, Morris J (2005) Applied numerical methods using MATLAB. Wiley, New Jersey

Shampine LF, Reichelt MW (1997) The MATLAB ODE suite. SIAM J Sci Comput 18:1–22

Nelder JA, Mead R (1965) A simplex method for function minimization. Comput J 7:308–313

Bello M, Tolaba MP, Aguerre RJ, Suarez C (2010) Modeling water uptake in a cereal grain during soaking. J Food Eng 97(1):95–100

Acknowledgments

This work was supported by the Coordination for the Improvement of Higher Education Personnel—CAPES—Brazil.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Nicolin, D.J., Jorge, R.M.M. & Jorge, L.M.M. Evaluation of distributed parameters mathematical models applied to grain hydration with volume change. Heat Mass Transfer 51, 107–116 (2015). https://doi.org/10.1007/s00231-014-1404-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-014-1404-3