Abstract

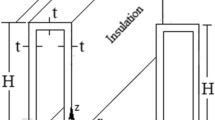

This paper investigates the thermal behaviour of two micro-channel elements cooled by Newtonian and non-Newtonian fluids, with the objective to maximise thermal conductance subject to constraints. This is done firstly for a two-dimensional duct micro-channel and secondly for a three-dimensional complex micro-channel. A numerical model is used to solve the governing equations relating to flow and temperature fields for both cases. The geometric configuration of each cooling channel is optimised for Newtonian and non-Newtonian fluid at a fixed inlet velocity and heat flux. In addition, the effect of porosity on thermal conductance is investigated. It was found, in both cases, that the non-Newtonian fluid characteristics result in a significant variation in thermal conductance as inlet velocity is increased. The characteristics of a dilatant fluid greatly reduce thermal conductance on account of shear thickening on the boundary surface. In contrast, a pseudoplastic fluid shows increased thermal conductance. A comparison of the complex micro-channel and the duct micro-channel shows the improved thermal conductance resulting from greater flow access to the conductive area, achieved by the complex micro-channel.

Similar content being viewed by others

Abbreviations

- A :

-

Total channel area (m2)

- C :

-

Global thermal conductance

- C p :

-

Specific heat (J/K)

- d :

-

Channel depth (m)

- D 1 :

-

Diameter of channel before branching (m)

- D 2 :

-

Diameter of channel after branching (m)

- H :

-

Total channel height (m)

- k :

-

Thermal conductivity (W/m K)

- K :

-

Consistency (Pa s0.5)

- L :

-

Total channel length (m)

- L 1 :

-

Length of channel before branching (m)

- L 2 :

-

Length of channel after branching (m)

- n :

-

Power law index

- P :

-

Pressure (Pa)

- q :

-

Total heat transfer (W)

- R :

-

Global thermal resistance

- Re :

-

Reynolds number

- T :

-

Temperature (K)

- U :

-

Average velocity (m/s)

- \( \overset{\lower0.5em\hbox{$\smash{\scriptscriptstyle\rightharpoonup}$}}{U} \) :

-

Velocity vector (m/s)

- V :

-

Total channel volume (m3)

- α :

-

Ratio of L 1 to L

- \( \dot{\gamma } \) :

-

Rate of strain

- θ :

-

Angle between branches (radians)

- μ :

-

Viscosity (kg/m s)

- ρ :

-

Density (kg/m3)

- φ :

-

Porosity ratio

- ~:

-

Dimensionless variable

- max :

-

Maximum

- in :

-

Inlet

References

Mudawar I (2001) Assessment of high-heat-flux thermal management schemes. IEEE Trans Compon Packag Technol 24:122–141

Rahman MM (2000) Measurement of heat transfer in microchannel heat sinks. Int Commun Heat Mass Transf 27:495–506

Toh KC, Chen XY, Chai JC (2002) Numerical computation of fluid flow and heat transfer in microchannels. Int J Heat Mass Transf 45:5133–5141

Li J, Peterson GP (2007) 3-Dimensional numerical optimization of silicon-based high performance parallel microchannel heat sink with liquid flow. Int J Heat Mass Transf 50:2895–2904

Fedorov AG, Viskanta R (2000) Three-dimensional conjugate heat transfer in the microchannel heat sink for electronic packaging. Int J Heat Mass Transf 43:399–415

Jung J, Oh H, Kwak H (2009) Forced convective heat transfer of nanofluids in microchannels. Int J Heat Mass Transf 52:466–472

Chein R, Huang G (2005) Analysis of microchannel heat sink performance using nanofluids. Appl Therm Eng 25:3104–3114

Wen D, Ding Y (2004) Experimental investigation into convective heat transfer of nanofluids at the entrance region under laminar flow conditions. Int J Heat Mass Transf 47:5181–5188

Barkhordari M, Etemad SG (2007) Numerical study of slip flow heat transfer of non-Newtonian fluids in circular microchannels. Int J Heat Mass Transf 28:1027–1033

Kim HW, Jeng DR, DeWitt KJ (1983) Momentum and heat transfer in power-law fluid flow over two dimensional or axisymmetrical bodies. J Heat Transf 26(2):245–259

Das S, Chakraborty S (2006) Analytical solutions for velocity, temperature and concentration distribution in electroosmotic microchannel flows of a non-Newtonian bio-fluid. Anal Chim Acta 559:15–24

Bello-Ochende T, Liebenberg L, Meyer JP (2007) Constructal cooling channels for micro-channel heat sinks. Int J Heat Mass Transf 50:4141–4150

Bejan A (2006) Constructal theory of pattern formation. Hydrol Earth Syst Sci Dis 3(4):1773–1807

Bejan A (2006) Constructal theory of design in engineering and nature. Therm Sci 10(1):9–18

Bejan A, Lorente S (2006) Constructal theory of generation of configuration in nature and engineering. J Appl Phys 100(4). doi:10.1063/1.2221896

Bello-Ochende T, Meyer JP, Ighalo FU (2010) Combined numerical optimization and constructal theory for the design of microchannel heat sinks. Numerical Heat Transfer, Part A 58:882–899

Bejan A, Lorente S (2008) Design with constructal theory. Wiley, USA

Balmforth NJ, Craster RV (2001) Geophysical aspects of non-Newtonian fluid mechanics. In: Balmforth NJ, Provenzale A (eds) Geomorpholohical Fluid Mechanics, Lecture Notes in Physics, vol 582. Springer, Heidelberg, pp 34–51

CD-Adapco (2011) StarCCM+ user guide 6.02.007

Hess WR (1914) Das Prinzip des kleinsten Kraftverbrauches im Dienste hämodynamischer Forschung. Archiv für Anatomie und Physiologie 1914:1–62

Murray CD (1926) The physiological principle of minimum work. The vascular system and the cost of blood volume. Proc Natl Acad Sci USA 12:207–214

Qu W, Mudawar I (2002) Analysis of three-dimensional heat transfer in micro-channel heat sinks. Int J Heat Mass Transf 45:3973–3985

Acknowledgments

The authors acknowledge with gratitude the funding obtained from the NRF, TESP, University of Stellenbosch/University of Pretoria, SANERI/SANEDI, CSIR EEDSM Hub and NAC and the National Research Foundation (NRF-DST), as well as support from Aerotherm.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Stocks, M.D., Bello-Ochende, T. & Meyer, J.P. Maximum thermal conductance for a micro-channel, utilising Newtonian and non-Newtonian fluid. Heat Mass Transfer 50, 865–875 (2014). https://doi.org/10.1007/s00231-014-1298-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-014-1298-0