Abstract

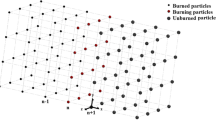

In the present paper, combustion of dust clouds from the discrete point heat source method has been addressed. Time-place temperature profile generated by single particle burning has been obtained to study the dust combustion. The summation of the temperature profiles of burned and burning particles predict the temperature in the preheating zone so that the ignition time of layer in flame front can be determined. Consequently the flame propagating speed was obtained based on the dust concentration corresponding to particles spacing and particle diameter. This method has been validated with aluminum dust cloud combustion. Decrease in the dust concentration leads to the lean limit of dust combustion. Increase in particles diameter or reduction in the dust concentration causes higher lean limit and also reduction in the flame propagating speed. Adding the ignition energy as igniter to this system, provides the path to study the effects of ignition energy in the dust combustion.

Similar content being viewed by others

Abbreviations

- A :

-

Area

- C d :

-

Dust concentration

- D :

-

Diameter

- H :

-

Convection coefficient

- i, j, k :

-

Components of Cartesian coordinate

- k :

-

Thermal conductivity

- L :

-

Distance of two adjacent particles or layers

- n :

-

Layer’s number, number of

- Q :

-

Heat released by igniter

- \(\dot{q}\) :

-

Particle burning heat release per second

- r :

-

Radius, radial distance

- t :

-

Time

- T :

-

Temperature

- x :

-

Axial distance

- a :

-

Burning zone

- f :

-

Flame

- ig :

-

Ignition temperature, due to igniter

- p :

-

Particle

- ∞ :

-

At infinity

- α :

-

Thermal diffusivity

- δ :

-

Dirac delta function

- ɛ :

-

Nondimensional time

- φ :

-

Nondimensional parameter

- η :

-

Nondimensional distance, nondimensional distance of two adjacent layers

- θ :

-

Nondimensional temperature

- ρ :

-

Density

- τ :

-

Particle burning time

- ψ :

-

Nondimensional temperature distribution due to igniter

- Φ :

-

Equivalence ratio

References

Haghiri A (2010) Analytical solution of pulsating flame. Thesis (MSc), Iran University of Science and Technology

Goroshin S, Tang FD, Higgins AJ, Lee J (2011) Laminar dust flames in a reduced-gravity environment. Acta Astronaut 68:656–666

Joseph G, Blair A, Barab J, Kaszniak M, MacKenzie C (2007) Combustible dust: a serious industrial hazard. J Hazard Mater 142:589–591

Eckhoff RK (2003) Dust explosions in the process industries, 3rd edn. Gulf Professional, USA

Abbasi T, Abbasi SA (2007) Dust explosions—cases, causes, consequences, and control. J Hazard Mater 140:7–44

Rashkovskiy SA, Kumar GM, Tewari SP (2010) One-dimensional discrete combustion waves in periodical and random systems. Combust Sci Technol 182:1009–1028

Li Q, Lin B, Li W, Zhai C, Zhu C (2011) Explosion characteristics of nano-aluminum powder–air mixtures in 20 L spherical vessels. Powder Technol 212:303–309

Crowe CT, Schwarzkopf JD, Sommerfeld M, Tsuji Y(1997) Multiphase flows with droplets and particles. CRC press

Seshadri K, Berlad AL, Tangirala V (1992) The structure of premixed particle-cloud flames. Combust Flame 89:333–342

Bidabadi M, Haghiri A, Rahbari A (2010) Mathematical modeling of velocity and number density profiles of particles across the flame propagation through a micro-iron dust cloud. J Hazard Mater 176:146–153

Rogachev AS, Shugaev VA, Kachelmyer CR, Varma A (1994) Mechanisms of structure formation during combustion synthesis of materials. Chem Eng Sci 49:4949–4958

Mukasyan AS, Hwang S, Sytchev AE, Rogachev AS, Merzhanov AG, Varma A (1996) Combustion wave microstructure in heterogeneous gasless systems. Combust Sci Technol 115:335–353

Hwang S, Mukasyan AS, Rogachev AS, Varma A (1997) Combustion wave microstructure in gas-solid reaction systems: experiments and theory. Combust Sci Technol 123:165–184

Tan FD, Higgins AJ, Goroshin S (2009) Effect of discreteness on heterogeneous flames: propagation limits in regular and random particle arrays. Combust Theory Model 13:319–341

Varma A, Mukasyan AS, Hwang S (2001) Dynamics of self-propagating reactions in heterogeneous media: experiments and model. Chem Eng Sci 56:1459–1466

Bidabadi M (1995) An experimental and analytical study of laminar dust flame propagation. Thesis (PhD), McGill University

Goroshin S, Lee J, Shoshin Y (1998) Effect of the discrete nature of heat sources on flame propagation in particulate suspensions. Combust Inst 27:743–749

Hanai H, Kobayashi H, Niioka T (2000) A numerical study of pulsating flame propagation in mixtures of gas and particles. Proc Combust Inst 28:815–822

Shoshin YL, Dreizin EL (2006) Particle combustion rates for mechanically alloyed Al–Ti and aluminum powders burning in air. Combust Flame 145:714–722

Marino TA (2008) Numerical analysis to study the effect of solid fuel particle characteristics on ignition, burning and radiative emission. Thesis (PhD), The George Washington University

Marion M, Chauveau C, Gokalp I (1995) Studies on the ignition and burning of aluminum particles, AIAA 95-2861

Boichuk LV, Shevchuk VG, Shvets AI (2002) Flame propagation in two-component aluminum–boron gas suspensions. Combust Explos Shock Waves 38:651–654

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bidabadi, M., Zadsirjan, S. & Mostafavi, S.A. The discrete heat source approach to dust cloud combustion. Heat Mass Transfer 50, 759–767 (2014). https://doi.org/10.1007/s00231-013-1283-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-013-1283-z