Abstract

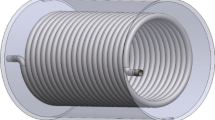

The study examined heat transfer of two dilute viscoelastic solutions in helical exchangers of circular cross-section. Ten helical coil heat exchangers with diameter ratios ranging from 4 to 50 were constructed. Results showed doubling the concentrations of polymer increased heat transfer performance by 12 %. The results were expressed in forms of some existing equations and were found to be in fair agreement to previous results.

Similar content being viewed by others

Abbreviations

- cp :

-

Specific heat

- d:

-

Tube diameter

- D:

-

Helix diameter of curvature

- Dn:

-

Dean number (Re(di/D)0.5)

- Gz:

-

Graetz number (mcp/kL)

- h:

-

Heat transfer coefficient

- hs :

-

Heat transfer coefficient, straight tube

- hc :

-

Heat transfer coefficient, curved tube

- k:

-

Thermal conductivity

- L:

-

Length

- m:

-

Mass

- Nu:

-

Nusselt number (hd/k)

- q:

-

Heat flux

- Q:

-

Volumetric flow rate (m3/s)

- Re:

-

Reynolds number (dvρ/μ)

- Pr:

-

Prandtl number (cpμ/k)

- T1 :

-

Inlet temp (°C)

- T2 :

-

Outlet temp (°C)

- Tw :

-

Average wall temp (°C)

- U:

-

Overall heat transfer coefficient

- v:

-

Velocity

- W:

-

Watt

- ρ:

-

Density

- μ:

-

Viscosity

- s:

-

Straight

- c:

-

Curved

- w:

-

Wall

- 1:

-

Inlet

- 2:

-

Outlet

References

Bergles AE (2011) Recent developments in enhanced heat transfer. Heat Mass Transf 47:1001–1008

Rogers GFC, Mayhew YR (1964) Heat transfer and pressure loss in helically helical tubes with turbulent flow. Int J Heat Mass Transf 7:1207–1216

Acharya N, Sen M, Chang HC (2001) Analysis of heat transfer enhancement in helical tube heat exchangers. Int J Heat Mass Transf 44:3189–3199

Cengiz Y, Yasar B, Dursun P (1995) Heat transfer and pressure drop in rotating helical pipes. Appl Energy 50(1):85–94

Kalb CE, Seader JD (1974) Fully developed viscous-flow heat transfer in curved circular tubes with uniform wall temperature. Am Inst Chem Eng J 20:340–346

Kubair V, Kuloor NR (1966) Heat transfer to Newtonian fluids in helical pipes in laminar flow. Int J Heat Mass Transf 9:63–75

Liu S, Masliyah JH (1994) Developing convective heat transfer in helical pipes with finite pitch. Int J Heat Fluid Flow 15(1):66–74

Naphon P, Wongwises S (2006) A review of flow and heat transfer characteristics in curved tubes. Renew Sustain Energy Rev 10:463–490

Patankar SV, Pratap VS, Spalding DB (1974) Prediction of laminar flow and heat transfer in helically helical pipes. J Fluid Mech 62:539–551

Prusa J, Yao LS (1982) Numerical solution for fully-developed flow in heated curved tubes. J Fluid Mech 123:503–522

Rindt CCM, Sillekens JJM, van Steenhoven AA (1999) The influence of the wall temperature on the development of heat transfer and secondary flow in a helical heat exchanger. Int Commun Heat Mass Transf 26:187–198

Seban RA, McLaughlin EF (1963) Heat transfer in tube coils with laminar and turbulent flow. Int J Heat Mass Transf 6:387–395

Tarbell JM, Samuels MR (1973) Momentum and heat transfer in helical coils. Chem Eng J 5:117–127

Shokouhmand H, Salimpour MR (2007) Entropy generation analysis of fully developed laminar forced convection in a helical tube with uniform wall temperature. Heat Mass Transf 44:213–220

Yang R, Chang CF (1994) Combined free and forced convection for developed flow in curved pipes with finite curvature ratio. Int J Heat Fluid Flow 15:470–476

Yang G, Dong F, Ebadian MA (1995) Laminar forced convection in a helicoidal pipe with finite pitch. Int J Heat Mass Transf 38:853–862

Zapryanov Z, Christov C, Toshev E (1980) Fully-developed laminar flow and heat transfer in curved tubes. Int J Heat Mass Transf 23:873–880

Mena B, Best G, Bautista P, Sanchez T (1978) Heat transfer in non-Newtonian flow through pipes. Rheol Acta 17(4):454–457

Hartnett JP, Kostic M (1985) Heat transfer to a viscoelastic fluid in laminar flow through a rectangular channel. Int J Heat Mass Transf 28(6):1147–1155

Yue P, Dooley J, Fenga JJ (2008) A general criterion for viscoelastic secondary flow in pipes of noncircular cross section. J Rheol 52(1):315–332

Siginer DA, Letelier MF (2010) Heat transfer asymptote in laminar flow of non-linear viscoelastic fluids in straight non-circular tubes. Int J Eng Sci 48(11):1544–1562

Agostini B, Watel B, Bontemps A, Thonon B (2002) Friction factor and heat transfer coefficient of R134a liquid flow in mini-channels. Appl Therm Eng 22(16):1821–1834

Ismail Z, Karim R (2012) Determination of optimum aspect ratio on laminar flow heat transfer of dilute viscoelastic solutions in flattened tube heat exchangers. J Heat Mass Transf 48(8):1319–1331

Tsang HY, James DF (1980) Reduction of secondary motion in curved tubes by polymer additives. J Rheol 24:589–601

Hsu C-F, Patankar SV (1982) Analysis of laminar non-Newtonian flow and heat transfer in curved tubes. Am Inst Chem Eng J 28(4):610–616

Inaba H, Aly WIA, Haruki N, Horibe A (2005) Flow and heat transfer characteristics of drag reducing surfactant solution in a helically coiled pipe. Heat Mass Transf 41(10):940–952

Ismail Z, Karim R (2012) Consolidation of heat transfer coefficients of viscoelastic simulated food solutions in helical exchangers. J Food Eng 108(1):122–127

Mori Y, Nakayama W (1967) Study on forced convection heat transfer in curved pipes. Int J Heat Mass Transf 10:681–694

Srinivasan PS, Nandapurkar SS, Holland FA (1968) Pressure drop and heat transfer in coils. Chem Eng (Lond) 218:113–119

Dravid AN, Smith KA, Merrill EW, Brain PLT (1971) Effect of secondary fluid motion on laminar flow heat transfer in helically helical tubes. Am Inst Chem Eng J 17:1114–1122

Ismail Z, Karim R (2012) Heat transfer of dilute polyacrylamide solutions in flattened tube exchangers. Exp Heat Transf. Accepted 27 Sept 2012

Ismail Z, Karim R (2012) Laminar flow heat transfer of dilute viscoelastic solutions in flattened tube heat exchangers. Appl Therm Eng 39:171–178

Author information

Authors and Affiliations

Corresponding authors

Appendix: Error estimates

Appendix: Error estimates

Density of water at 20 °C = 0.9982 g/l

Density of water at 40 °C = 0.9922 g/l

Error in assuming constant density = 0.006/0.9952 approximately = 0.5 %

Average flowrate = 10 ml/s

The gear pump was calibrated to read up to an accuracy of 0.2 ml/s

Average error in measuring volumetric flowrate = 0.2/10 approximately = 2 %

Error in obtaining mass flowrate = (0.5 + 2)% = 2.5 %

Error in assuming constant specific heat = 0.004/1.000 approximately = 0.5 %

Thermal conductivity at 285 K = 0.5818 w/(mK)

Thermal conductivity at 300 K = 0.6096 w/(mK)

Error in assuming constant thermal conductivity = 0.0278/0.5957 approximately = 5 %

Average length of exchanger tubes = 74.81 cm

Estimated error in length = 0.5/74.81 approximately = 0.5 %

Average error in Graetz Number (mcp/kL) = (2.5 + 0.5 + 5 + 0.5) % = 8.5 %

Average internal diameter is obtained by back-calculating from internal volumes and length of tubes. This gives an error of less than 2 %.

Velocity is proportional to Flowrate/(diameter)2

Error in velocity = (2.5 + 4) % = 6.5 %

Variations of viscosities and temperature for the solutions were experimentally determined.

Estimated error in reading from the calibration curves is about 1 %

Estimated error in Reynolds Number = (2 + 6.5 + 1) % = 9.5 %

Average diameter of curvature = 141.4 mm

Error in diameter of curvature = 0.5/141.4 approximately = 0.4 %

Error in Dean Number [Re(di/D)0.5] = [9.5 + (2 + 0.4)/2] % = 10.7 %

Overall error in Prandtl Number (cpμ/k) = (0.5 + 1 + 5) % = 6.5 %.

Error associated with using the Mori and Nakayama form = [(8.5/3) + (10.7/2)] % = 8.18 %

Error associated with using the Dravid form = [(10.7/2) + (6.5 × 0.175)] % = 6.5 %

Error associated with using the Cengiz form = [(10.7 × 0.864) + (6.5 × 0.4)] % = 11.8 %

Error associated with using the Kalb and Seader form = [(10.7*0.5) + (6.5*0.1)] % = 6 %.

Rights and permissions

About this article

Cite this article

Ismail, Z., Karim, R. Heat transfer of dilute viscoelastic solutions in helical exchangers. Heat Mass Transfer 49, 711–721 (2013). https://doi.org/10.1007/s00231-013-1113-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-013-1113-3