Abstract

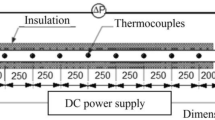

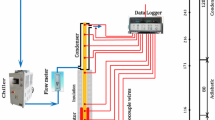

This article describes experimental investigations of the heat transfer coefficient and pressure drop of R-134a flowing inside internally grooved tubes. The test tubes are one smooth tube and four grooved tubes. All test tubes are made from type 304 stainless steel, have an inner diameter of 7.1 mm, are 2,000 mm long and are installed horizontally. The test section is uniformly heated by a DC power supply to create evaporation conditions. The groove depth of all grooved tubes is fixed at 0.2 mm. The experimental conditions are conducted at saturation temperatures of 20, 25 and 30°C, heat fluxes of 5, 10 and 15 kW/m2, and mass fluxes of 300, 500 and 700 kg/m2 s. The effects of groove pitch, mass flux, heat flux, and saturation temperature on heat transfer coefficient and frictional pressure drop are discussed. The results illustrate that the grooved tubes have a significant effect on the heat transfer coefficient and frictional pressure drop augmentations.

Similar content being viewed by others

Abbreviations

- A :

-

surface area of the test section (m2)

- c p :

-

specific heat at constant pressure (J/kg K)

- G :

-

mass flux (kg/m2 s)

- h :

-

heat transfer coefficient (W/m2 K)

- I :

-

current (A)

- i :

-

enthalpy (J/kg)

- k :

-

thermal conductivity (W/m K)

- L :

-

length of the test tube (m)

- \( \dot{m} \) :

-

mass flow rate (kg/s)

- N :

-

number of the thermocouples on the inner wall surface

- ∆P :

-

pressure drop (Pa)

- \( \dot{Q} \) :

-

heat transfer rate (W)

- q′′:

-

heat flux (W/m2)

- r :

-

radius (m)

- T :

-

temperature (oC)

- V :

-

voltage (V)

- x :

-

average vapour quality

- X :

-

position of the test section (m)

- ρ:

-

density (kg/m3)

- α:

-

void fraction

- a:

-

acceleration

- avg:

-

average

- f:

-

friction

- g:

-

gravity

- in:

-

inlet

- i:

-

inside

- l:

-

liquid

- out:

-

outlet

- o:

-

outside

- ph:

-

pre-heater

- ref:

-

refrigerant

- sat:

-

saturation

- TS:

-

test section

- v:

-

vapor

- w:

-

water

- wall:

-

wall surface

References

International Institute of Refrigerant (1997) 12th Informatory Note on Fluorocabons and Refrigeration

Herman C, Kang E (2002) Heat transfer enhancement in a grooved channel with curved vanes. Int J Heat Mass Transfer 45:3741–3757

Bilen K, Cetin M, Gul H, Balta T (2009) The investigation of groove geometry effect on heat transfer for internally grooved tubes. Appl Thermal Eng 29:753–761

Bharadwaj P, Khondge AD, Date AW (2009) Heat transfer and pressure drop in a spirally grooved tube with twisted tape insert. Int J Heat Mass Transfer 52:1938–1944

Graham D, Chato JC, Newell T (1999) Heat transfer and pressure drop during condensation of refrigerant 134a in an axially grooved tube. Int J Heat Mass Transfer 42:1935–1944

Goto M, Inoue N, Yonemoto R (2003) Condensation heat transfer of R410A inside internally grooved horizontal tubes. Int J Refrig 26:410–416

Zhang X, Zhang X, Chen Y, Yuan X (2008) Heat transfer characteristics for evaporation of R417A flowing inside horizontal smooth and internally grooved tubes. Energy Convers Managet 49:1731–1739

Tran TN (1998) Pressure drop and heat transfer study of two-phase flow in small channels. Ph.D. Dissertation, Texas Tech University, Lubbock

Zivi SM (1964) Estimation of steady-state steam void-fraction by mean of the principle of minimum entropy production. Trans ASME J Heat Transfer 86:247–252

Chaddock JB, Noerager JA (1966) Evaporation of refrigerant 12 in a horizontal tube with constant wall heat flux. ASHRAE Trans 72:90–101

Choi TY, Kim YJ, Kim MS, Ro ST (2000) Evaporation heat transfer of R-32, R-134a, R-32/134a, and R-32/125/134a inside a horizontal smooth tube. Int J Heat Mass Transfer 43:3651–3660

Wongsa-ngam J, Nualboonrueng T, Wongwises S (2004) Performance of smooth and micro-fin tubes in high mass flux region of R-134a during evaporation. Heat Mass Transfer 10:425–435

Lockhart RW, Martinelli RC (1949) Proposed correlation of data for isothermal two-phase, two-component flow in pipes. Chem Eng Prog 45:39–48

Soliman HM, Azer NZ (1971) Flow patterns during condensation inside a horizontal tube. ASHRAE Trans 77:210–224

Friedel L (1979) Improved friction pressure drop correlations for horizontal and vertical two-phase pipe flow. The European Two-Phase Flow Group Meeting, Paper E2. Ispra, Italy

Acknowledgments

The present study was supported financially by the Thailand Research Fund (TRF), the Office of the Higher Education Commission and the National Research University Project, whose guidance and assistance are gratefully acknowledged. The authors also wish to acknowledge Thai-German Products Public Company Limited for providing the test tubes.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wongwises, S., Laohalertdecha, S., Kaew-on, J. et al. Evaporation heat transfer and flow characteristics of R-134a flowing through internally grooved tubes. Heat Mass Transfer 47, 629–640 (2011). https://doi.org/10.1007/s00231-010-0748-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-010-0748-6