Abstract

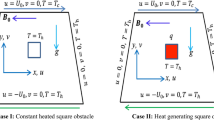

This work experimentally studies the flow characteristics and forced convective heat transfer in a sintered porous channel that filled with sintered copper beads of three average diameters ( \(\overline{{d}} = 0.704,\) 0.830, and 1.163 mm). The pressure drop and the local temperature measurements can be applied to figure out the distributions of the friction coefficient and the heat transfer coefficient. Three sintered porous channels differ in the arrangement of obstacle blocks. Model A has no obstacle. Models B and C have five obstacle blocks facing down and up, respectively, in a sintered porous channel. The range of experimental parameters, porosity, heat flux, and effect of forced convection are 0.370 ≤ ɛ ≤ 0.385, q=0.228, 0.872, 1.862 W/cm2, and 200 ≤ Re d ≤ 800. The permeability and inertia coefficient of each of the three sintered porous channels are analyzed. The results for Model A agree with those obtained by previous investigations in C f distribution. The heat transfer of Model C exceeds that of Model A by approximately 20%. Finally, a series of empirical correlation equations were obtained for practical applications and engineering problems.

Similar content being viewed by others

Abbreviations

- C f :

-

friction factor, \(\left(\frac{\Delta {P}}{{L}}\right)\frac{{\overline{{d}} }}{\rho U^{2}}\frac{\varepsilon ^{3} }{(1 - { \varepsilon)}}\)

- C n :

-

heat loss coefficient

- D e :

-

hydraulic diameter for sintered porous channel, m

- d :

-

copper bead diameter, mm

- F :

-

inertia coefficient constant

- H :

-

channel height, m

- h :

-

local heat transfer coefficient, q/(T w − T b), W/m2 K or height of obstacle block, mm

- I :

-

electric current, A

- K :

-

permeability, ɛ 3 d 2/[150(1 − ɛ)2 ], m2

- k e :

-

effective thermal conductivity, W/m K

- L :

-

length of test section, m

- N :

-

number of copper bead

- Nu :

-

Nusselt number, \(\overline{h} {D}_{\rm e}/{k}_{\rm e} \)

- n :

-

number of obstacle blocks

- P w :

-

perimeter of the test section, m

- Pr :

-

Prandtl number

- Q :

-

power input, W

- q :

-

wall heat flux per unit area, W/m2

- Re d :

-

particle Reynolds number, \( \rho \overline{U}d/\mu \)

- T :

-

temperature, °C

- u :

-

volume average velocity, \(\frac{1}{v}\int\limits_{v} U{\rm d}v,\) m/s

- V :

-

voltage, V

- v :

-

volume, m3

- X :

-

axial local position

- ℓ:

-

length of obstacle block, mm

- ɛ:

-

porosity

- μ:

-

viscosity, kg/m s

- ν:

-

kinematic viscosity, m2/s

- ρ:

-

density, kg/m3

- ϕ:

-

amendment porosity, \(\phi = 1 - \frac{{nwh}}{{\ell }}\)

- \(\bar{\,} \) :

-

average value

- b:

-

bulk temperature

- F:

-

fluid

- in:

-

measured position at inlet

- loc:

-

local

- loss:

-

heat loss

- out:

-

measured position at exit

- w:

-

quantity based on the wall

- ∞:

-

ambient

References

Hadim A (1994) Forced convection in a porous channel with localized heat sources. ASME J Heat Transfer 116:465–472

Peterson GP, Chang CS (1998) Two-phase heat dissipation utilizing porous-channels of high-conductivity material. ASME J Heat Transfer 120:243–252

Calmidi VV, Mahajan RL (2000) Forced convection in porosity metal foams. ASME J Heat Transfer 122:557–565

Kim SY, Kang BH, Kim JH (2001) Forced convection from aluminum foam materials in an asymmetrically heated channel. Int J Heat Mass Transfer 44:1451–1454

Jiang PX, Li M, Lu TJ, Y L, Ren ZP (2004) Experimental research on convection heat transfer in sintered porous plate channels. Int J Heat Mass Transfer 47:2085–2096

Jiang PX, Xu YJ, Lv J, Shi RF, He S, Jackson JD (2004) Experimental investigation of convection heat transfer of CO2 at super-critical pressures in vertical mini-tubes and in porous media. Appl Therm Eng 24:1255–1270

Singh R, Kasana HS (2004) Computational aspects of effective thermal conductivity of highly porous metal foams. Appl Therm Eng 24:1841–1849

Hwang GJ, Chao CH (1994) Heat transfer measurement and analysis for sintered porous channels. J Heat Transfer 116:456–464

Lchimiya K (1999) A new method for evaluation of heat transfer between solid material and fluid in a porous medium. ASME J Heat Transfer 121:978–983

Hwang JJ, Hwang GJ, Yeh RH, Chao CH (2002) Measurement of interstitial convective heat transfer and frictional drag for flow across metal foams. ASME J Heat Transfer 124:120–129

Kim SJ, Yoo JW, Jang SP (2002) Thermal optimization of a circular-sectored finned tube using a porous medium approach. J Heat Transfer 124:1026–1033

Leong KC, Jin LW (2004) Heat transfer of oscillating and steady flows in a channel filled with porous media. Int Commun Heat Mass Transfer 31:63–72

Hwang GJ, Cheng YC, Chiang YW (1997) An experimental study of laminar heat transfer in a one-porous-wall square duct with suction flow. Int J Heat Mass Transfer 40:481–485

Amiri A, Vafai K (1994) Analysis of dispersion effect and nonthermal equilibrium, non-Darcy variable porosity incompressible flow through porous media. Int J Heat Mass Transfer 37:939–954

Hwang JJ (1997) Turbulent heat transfer and fluid flow in a porous-baffled channel. J Thermophys Heat Transfer 11:429–436

Hwang JJ (1998) Heat transfer–friction characteristic comparison in rectangular ducts with slit and solid ribs mounted on one wall. ASME J Heat Transfer 120:709–716

Ould-Amer Y, Chink S, Bouhadef K, Lauriat G (1998) Forced convection cooling enhancement by use of poous materials. Int J Heat Fluid Flow 19:251–258

Lee KT, Yan WM (1998) Mixed convection heat transfer in horizontal ducts with wall transpiration effects. Int J Heat Mass Transfer 41:411–423

Liu HC, Yan WM, Soong CY, Chen F (2005) Effects of baffle-blocked flow channel on reactant transport and cell performance of a proton exchange membrane fuel cell. J Power Sources 142:125–133

Soong CY, Yan WM, Tzeng CY, Liu HC, Chen F, Chu HS (2005) Analysis of reactant gas transport in a PEM fuel cell with partially-blocked flow channel design. J Power Sources 143:36–47

Kline SJ, McClintock FA (1953) Describing uncertainties in single sample experiments. Mech Eng January, 3–8

Hunt ML, Tien CL (1988) Effects of thermal dispersion on forced convection in fibrous media. Int J Heat Mass Transfer 31:301–309

Jones DP, Krier H (1983) Gas flow resistance measurements through packed beds at high Reynolds numbers. ASME J Fluids Eng 105:168–173

Ergun S (1952) Fluid flow through packed columns. Chem Eng Prog 48:89–94

Wu CC, Hwang GJ (1998) Flow and heat transfer characteristics inside packed and fluidized beds. ASME J Heat Transfer 120:667–673

Kar KK, Dybbs A (1982) Internal heat transfer coefficients of porous metals, the winter annual meeting of ASME, Phoenix, Arizona, pp 81–89

Dittus FW, Boelter LMK (1930) Heat transfer in automobile radiators of the tubular type. University of California Publications in Engineering 2:443–461, reprinted in Int Commun Heat Mass Transfer 12 (1985) 3–22.

Acknowledgements

The authors would like to thank the National Science Council of Taiwan, Republic of China, for financially supporting this research under Contract No. NSC 92-2622-E-270-003-CC3.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tzeng, SC., Ma, WP. & Wang, YC. Friction and forced convective heat transfer in a sintered porous channel with obstacle blocks. Heat Mass Transfer 43, 687–697 (2007). https://doi.org/10.1007/s00231-006-0149-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-006-0149-z