Abstract

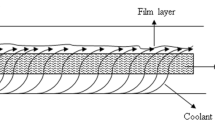

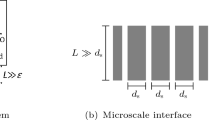

A transient, one-dimensional numerical model is developed to describe the processes of transpiration cooling and ablation of the porous matrix used for the cooling. This model is based on the assumption of local thermal equilibrium. The problem of moving boundary due to ablation of the porous matrix is treated by the front-fixing method. This paper discusses the results of numerical simulations under different conditions and control parameters of ablation process. It was found that cooling effects and ablation processes are influenced by the coolant mass flow rate, the intensity of the heat flux, and the initial temperature at the start of transpiration cooling. In additional to the above three parameters, the Stefan number and the Biot number can also influence the transient cooling process, control ablative thickness of the porous plate by the reduction of ablative speed and duration, respectively.

Similar content being viewed by others

Abbreviations

- a :

-

specific surface area of porous matrix

- c :

-

specific heat capacity [J/(kg K)]

- D :

-

hydraulic diameter of coolant channel (m)

- k :

-

thermal conductivity [W/(m K)]

- s 0 :

-

initial plate thickness (m)

- d p :

-

characteristic size of porous matrix (m)

- h :

-

heat transfer coefficient [W/(m2K)]

- s :

-

ablation thickness (m)

- \(\tilde{S}\) :

-

dimensionless thickness

- T :

-

temperature (K)

- θ:

-

dimensionless temperature

- v :

-

velocity (m/s)

- t :

-

time (s)

- τ:

-

dimensionless time

- y :

-

coordinate

- Y :

-

dimensionless coordinate

- \(\dot{q}\) :

-

heat flux (W/m2)

- Q :

-

dimensionless heat flux

- \(\dot{m}_{\rm f}\) :

-

coolant mass flow rate [kg/(m2 s)]

- M :

-

dimensionless coolant flow rate

- L :

-

latent heat of solid material (J/kg)

- Ste:

-

Stefan number

- Pr:

-

Prandtl number

- Bi:

-

Biot number

- ɛ:

-

porosity

- ρ:

-

density (kg/m3)

- μ:

-

viscosity, (kg/m s)

- α:

-

thermal diffusivity (m2/s)

- 0:

-

initial time

- f:

-

coolant fluid

- c:

-

constant/coolant at entry of channel

- eff:

-

effective

- s:

-

solid matrix

References

Hartnett JP, Eckert ERG (1957) Mass transfer cooling in a laminar boundary layer with constant fluid properties. Trans Am Soc Mech Eng 79:247–254

Choi SH, Scotti SJ, Song KD, Reis H (1997) Transpiration cooling of a scram jet engine combustion chamber, the 32th AIAA thermophysics conference, Atlanta, Georgia, 1997, AIAA 97-2576

Glass DE, Dilley AD. Numerical analysis of convection/transpiration cooling, NASA/TM −1999–209828

Andoh YH, Lips B (2003) Predication of porous walls thermal protection by effusion or transpiration cooling: an analytical approach. Appl Thermal Eng 23:1947–1958

Trevino C, Medina A (1999) Analysis of the transpiration cooling of a thin porous plate in a hot laminar convective flow. Eur J Mech B Fluids 18(2):245–260

Landis JA, Bowman WJ. Numerical study of a transpiration cooled rocket nozzle, AIAA Paper 96–2580

Keener D, Lenertz J, Bowersox R, Bowman J (1995) Transpiration cooling effects on nozzle heat transfer and performance. J Spacecr Rockets 32:981–985

Lewis DJ, Anderson LP. Effects of melt-layer formation on ablative materials exposed to highly aluminized rocket motor plumes, AIAA Paper 98–0872

Yang BC, Cheung FB. Numerical investigation of thermal–chemical and mechanical erosion of ablative materials, AIAA Paper 93–2045

Amiri A, Vafai K (1995) Effects of boundary conditions on non-darcian heat transfer through porous media and experimental comparisons. Numer Heat Transfer Part A 27:651–664

Amiri A, Vafai K (1998) Transient analysis of incompressible flow through packed bed. Int J Heat Mass Transfer 41:4259–4279

Wakao N, Kaguei S (1982) Heat and mass transfer in packed beds. Gordon and Breach Science Publishers Inc., New York

Kim SJ, Jang SP (2002) Effects of the Darcy number, the Prandtl number, and the Reynolds number on local thermal non-equilibrium. Int J Heat Mass Transfer 45:3885–3896

Kar KK, Dybbs A (1982) Internal heat transfer coefficient of porous metals. In: ASME proceedings of the winter annual meeting, Phoenix, Az. 1982, pp 81–91

Glass DE, Dilley AD (2001) Numerical analysis of convection/transpiration cooling. J Spacecr Rockets 38(1):15–20

Landis JA, Bowman WJ (1996) Numerical study of a transpiration cooled rocket nozzle, AIAA, ASME, SAE, and ASEE, joint propulsion conference and exhibit, 1996, AIAA Paper 96–2580

Stefan J (1889) Ueber die Theorie der Eisbildung, insbesondere ueber die Eisbildung im Palarmeere, Wien. Akad Mat Naturw 98(11a):965–983

Landau HG (1950) Heat conduction in a melting solid. Q Appl Math 8:81–94

Zhang YW, Faghri A (1999) Melting of a subcooled mixed powder bed with constant heat flux heating. Int J Heat Mass Transfer 42:775–788

Christoper DM (2001) Comparison of interface-following techniques for numerical analysis of phase-change problem. Numer Heat Transfer Part B 39:189–206

Khosla PK, Rubin SG (1974) A diagonally dominant second order accurate implicit scheme. Comput Fluid 2:207–209

Gonzo EE (2002) Estimating correlations for the effective thermal conductivity of granular materials. Chem Eng J 90:299–302

Acknowledgements

The financial support provided by NSFC (No. 90305006) and EMNSFA (No. 2004kj365zd) is greatly appreciated. One of the authors (Jianhua Wang) is also grateful for the financial support provided by the Foundation of the Education Ministry of China for the Returned Overseas Scholars.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, J., Wang, H., Sun, J. et al. Numerical simulation of control ablation by transpiration cooling. Heat Mass Transfer 43, 471–478 (2007). https://doi.org/10.1007/s00231-006-0130-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-006-0130-x