Abstract

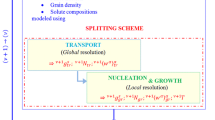

In the present study, two numerical approaches for single-domain modelling of microsegregation during solidification of binary alloys are presented. In the first approach, the concentration jump at the moving solid/liquid interface is formulated using a volumetric term and a Boolean function. The governing solute redistribution equation, valid for the whole domain comprising the solid and liquid regions, is derived in terms of the liquid phase composition. The effects of microstructure coarsening on microsegregation has been described and included in the model. In the second approach, the continuum mixture theory is utilized to derive a single domain solute redistribution equation in terms of the mixture composition. The solidification front motion and dendrite arm coarsening effects are accommodated by considering the representative elementary volume to consist of solid, interdendritic, and extradendritic liquid phases. Numerical solutions have been obtained using a control-volume based finite-difference method with a fixed grid. Good agreement has been observed between the predictions of the present fixed-domain models and the exact analytical and experimental results.

Similar content being viewed by others

Abbreviations

- A :

-

Constant (m3/s)

- C m :

-

Total solute quantity in the domain

- C o :

-

Initial alloy concentration

- D α :

-

Mass diffusion coefficient (m2/s)

- f :

-

Mass fraction

- f α :

-

Solute concentration

- f k :

-

Mass fraction of phase k

- Fo :

-

Fourier number (D αs t f/X 2f )

- g :

-

Volume fraction

- i f :

-

Phase change node

- J k :

-

Surface diffusion flux (kg/ms)

- k p :

-

Partition coefficient

- M :

-

Number of space steps in x direction

- N :

-

Number of space steps in y direction

- \(\vec n\) :

-

Outward normal to the s/l interface

- S k :

-

Volumetric source term

- t :

-

Time (s)

- T :

-

Temperature (K)

- t f :

-

Final solidification time (s)

- u, v :

-

Velocities in x and y directions (m/s)

- V d :

-

Coarsening velocity (m/s)

- V f :

-

Solidification front velocity (m/s)

- X F :

-

1-D domain size (m)

- X s :

-

Position of the interface (m)

- τ:

-

Dimensionless time = t/t f

- Δt :

-

t time step (s)

- Δx, Δy :

-

Control volume size (m)

- \(\bar{\rho}_{{{\rm k}}}\) :

-

Partial density of phase k (kg/m3)

- λ2 :

-

Secondary dendrite arm spacing (m)

- λ1 :

-

Primary dendrite arm spacing (m)

- -:

-

Volume averaged value

- α:

-

Solute

- o :

-

Previous time step

- d:

-

Dendritic liquid

- eut:

-

Eutectic

- f:

-

Final

- i:

-

Interface

- k:

-

Phase

- l:

-

Liquid (extradendritic liquid)

- liq:

-

Liquidus

- m:

-

Mixture

- p:

-

Central node point

- s:

-

Solid

- s, n, w, e:

-

South, north, west, east faces of control volume

- S, N,W, E:

-

South, north, west, east nodes

References

Brody HD, Flemings MC (1966) Solute redistribution during dendritic solidification. Trans Met Soc AIME 236:615–624

Clyne WT, Kurz W (1981) Solute redistribution during solidification with rapid state diffusion. Met Trans 12A:965–971

Ohnaka I (1986) Mathematical analysis of solute redistribution during solidification with diffusion in solid phase. Trans ISIJ 26:1045–1051

Kobayashi S (1988) Solute redistribution during solidification with diffusion in solid phase: a theoretical analysis. J Cryst Growth 88:87–96

Voller VR, Sundarraj S (1993) Modelling of microsegregation. Mater Sci Technol 9:474–481

Voller R, Beckermann C (1999) A unified model of microsegregation and coarsening. Metall Mater Trans 30A:2183–2189

Voller VR (2000) A model for microsegregation during binary alloy solidification. Int J Heat Mass Transfer 43:2047–2052

Boettinger WJ, Warren JA, Beckermann C, Karma A (2002) Phase-field simulation of solidification. Annu Rev Mater Res 32:163–194

Loginova L, Amberg G, Agren J (2001) Phase-filed simulations of non-isothermal binary alloy solidification. Acta Mater 49:573–581

Bennon WD, Incropera FP (1987) A continuum model for momentum, heat and species transport in binary solid-liquid phase change systems-I. model formulation. Int J Heat Mass Transfer 30:2161–2170

Beckerman C, Viskanta R (1988) Double-diffusive convection during dendritic solidification of a binary mixture. Physico Chem Hydro 10:195–213

Voller VR, Brent AD, Prakash C (1989) The Modeling of heat, mass and solute transport in solidification systems. Int J Heat Mass Transfer 32:1719–1731

Wang CY, Beckermann C (1993) Unified solute diffusion model for columnar dendritic and equiaxed dendritic alloy solidification. Mater Sci Eng 171:199–211

Wang CY, Beckerman C (1994) Multi-scale/phase modelling of dendritic alloy solidifcation, ASME HTD-Vol. 284/AMD-Vol. 182, Transport phenomena in solidification, pp 75–95

Arquis E, Rady M (2005) A fixed domain model for micrsegregation during solidification of binary alloys. Heat Mass Transfer 41:545–558

Kim JH, Park JW, Lee CH, Yoon EP (1997) Numerical modelling of microsegregation in binary alloys. J Cryst Growth 137:550–560

Trivedi R (1984) Interdendritic spacing: Part II. A comparison of theory and experiment. Met Trans A 15:977–982

Young KP, Kirkwood DH (1975) The dendrite arm spacings of aluminum-copper alloys solidified under steady state conditions. Met Trans 6A:197–205

Flemings MC, Kattamis TZ, Bardes BP (1991) Dendrite arm spacing in aluminum alloys. AFS Trans 99:501–506

Somboonsuk K, Mason JT, Trivedi R (1984) Interdenritic spacings: Part I Experimental studies. Met Trans 15A:967–975

Kirkwood DH (1985) A simple model for dendritic arm coarsening during solidification.Mater Sci Eng 73:L1–L4

Patankar SV (1980) Numerical heat transfer and fluid flow. Hemisphere, New York

Ni J, Incropera FP (1995) Extension of the continuum model for transport phenomena occurring during metal alloy solidification-I. The conservation equations. Int J Heat Mass Transfer 38:1271–1284

Sarreal JA, Abbaschian GH (1986) Effect of solidification rate on microsegregation. Met Trans 17A:2063–2073

Sundarraj S, Voller V (1994) A dual scale model for segregation phenomena, in transport phenomena in solidification. ASME HTD 284:29–41

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rady, M.A., Arquis, E. Numerical Approaches for microscopic modelling of solute redistribution during solidification of binary alloys. Heat Mass Transfer 42, 347–358 (2006). https://doi.org/10.1007/s00231-005-0022-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-005-0022-5