Abstract

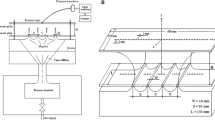

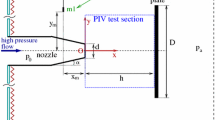

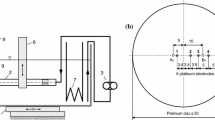

The flow characteristics of both confined and unconfined air jets, impinging normally onto a flat plate have been experimentally investigated. The mean and turbulence velocities, and surface pressures were measured for Reynolds numbers ranging from 30,000 to 50,000 and the nozzle-to-plate spacings in range of 0.2–6. Smoke-wire technique is used to visualize the flow behavior. The effects of Reynolds number, nozzle-to-plate spacing and flow confinement on the flow structure are reported. In the case of confined jet, subatmospheric regions occur on both impingement and confinement surfaces at nozzle-to-plate spacings up to 2 for all Reynolds numbers in consideration and they lie up to nearly the same radial location at both surfaces. However, there is no evidence of the subatmospheric region in unconfined jet. It is concluded that there exists a linkage among the subatmospheric region, turbulence intensity and the peaks in heat transfer coefficients for low spacings in impinging jets.

Similar content being viewed by others

Abbreviations

- C p :

-

Pressure coefficient

- D :

-

Nozzle diameter, m

- H :

-

Nozzle-plate spacing, m

- ΔP :

-

Difference between the surface pressure and the atmospheric pressure, N/m2

- r :

-

Radial distance measured from the stagnation point, m

- Re :

-

Nozzle Reynolds number, U o D/ν

- u :

-

Local radial velocity, m/s

- v :

-

Local axial velocity, m/s

- u′:

-

Turbulence velocity (rms) in the radial direction, m/s

- v′:

-

Turbulence velocity (rms) in the axial direction, m/s

- U 0 :

-

Nozzle exit velocity, m/s

- z :

-

Axial distance measured from the nozzle exit, m

- ν:

-

Kinematic vicosity of air, m2/s

- ρ:

-

Density of air, kg/m3

References

Jambunathan K, Lai E, Moss MA, Button BL (1992) A review of heat transfer data for single circular jet impingement. Int Heat Fluid Flow 13:106–115

Gardon R Akfirat JC (1965) The role of turbulence in determining the heat transfer characteristics of impinging jets. Int J Heat Mass Transfer 8:1261–1272

Obot NT, Mujumdar AS, Douglas WJM (1982) Effect of semi confinement on impinging heat transfer. In: Proceeding of 7th International Heat Transfer Conference 3:395–400

Hollworth BR, Wilson SI (1984) Entrainment effects on impingement heat transfer: part I-measurements of heated jet velocity and temperature distributions and recovery temperatures on target surface. ASME J Heat Transfer 106:797–803

Goldstein RJ, Sobolik KA, Seol WS (1990) Effect of entrainment on the heat transfer to a heated circular air jet impinging on a flat surface. ASME J Heat Transfer 112:608–611

Fitzgerald JA, Garimella SV (1997) Flow field effects on heat transfer in confined jet impingement. ASME J Heat Transfer 119:630–632

Ashfort-Frost S, Jambunathan K, Whithney CF (1997) Velocity and turbulence characteristics of a semiconfined orthogonally impinging slot jet. Exp Thermal Fluid Sci 14:60–67

Baughn JWB, Shimizu S (1989) Heat transfer measurements from a surface with uniform heat flux and an impinging jet. ASME J Heat Transfer 111:1096–1098

Behnia M, Parneix S, Shabany Y, Durbin PA (1999) Numerical study of turbulent heat transfer in confined and unconfined impinging jets. Int Heat Fluid Flow 20:1–9

Colucci DW, Viskanta R (1996) Effect of nozzle geometry on local convective heat transfer to a confined impinging air jet. Exp Thermal Fluid Sci 13:71–80

Garimella SV, Rice RA (1995) Confined and submerged liquid jet impingement heat transfer. ASME J Heat Transfer 117:871–877

Ichimiya K, Yamada Y (2003) Three dimensional heat transfer of a confined circular impinging jet with buoyancy effects. ASME J Heat Transfer 125:250–256

San JY, Huang CH, Shu MH (1997) Impingement cooling of a confined circular air jet. Int J Heat Mass Transfer 40:1355–1364

Schafer DM, Ramadhyani S, Incropera FP (1992) Numerical simulation of laminar convection heat transfer from an in-line array of discrete sources to a confined rectangular jet. Numer Heat Transfer 22:121–141

Tavfek AA (1996) Heat transfer and pressure distributions of an impinging jet on a flat surface. Heat Mass Transfer 32:49–54

Lytle D, Webb BW (1994) Air jet impingement heat transfer at low nozzle-plate spacings. Int J Heat Mass Transfer 37:1687–1697

Sun H, Ma CF, Nakayama W (1993) Local characteristics of convective heat transfer from simulated microelectronic chips to impinging submerged round water jets. ASME J Electron Packaging 115:71–77

Huber AM, Viskanta R (1994) Convective heat transfer to a confined impinging array of air jets with spent air exits. ASME J Heat Transfer 116:570–576

Walker JDA, Smith CR, Cerra AW, Doligalski TL (1987) Jet impact of a vortex ring on a wall. J Fluid Mech 181:99–140

Baydar E (1999) Confined impinging air jet at low Reynolds numbers. Exp Thermal Fluid Sci 19:27–33

Baydar E, Ozmen Y (2005) An experimental and numerical investigation on a confined impinging air jet at high Reynolds numbers. Appl Thermal Eng 25:409–421

Chalupa R, Chen M, Modi V, West AC (2001) High Schmidt mass transfer in a turbulent impinging slot-jet flow. Int J Heat Mass Transfer 44:3775–3785

Cooper D, Jackson DC, Launder BE, Liao GX (1993) Impinging jet studies for turbulence model assessment-I. Flow-field experiments. Int J Heat Mass Transfer 36:2675–2684

Narayanan V, Seyed-Yagoobi J, Page RH (2004) An experimental study of fluid mechanics and heat transfer in an impinging slot jet flow. Int J Heat Mass Transfer 47:1827–1845

Saad NR, Polat S, Douglas WJM (1992) Confined multiple impinging slot jets without crossflow effects. Int Heat Fluid Flow 13:2–14

Cornaro C, Fleischer AS, Goldstein RJ (1999) Flow visualization of a round jet impinging on cylindrical surfaces. Exp Thermal Fluid Sci 20:66–78

Tràvníček Z, Tesař V (2004) Annular impinging jet with recirculation zone expanded by acoustic excitation. Int J Heat Mass Transfer 47:2329–2341

Model 1125/1125R-1 Calibrator/Probe Rotator, Instruction Manuel, T.S.I. Incorporated, P/N 1990113 Revision F, St. Paul, 1987

Livingood JNB, Hrycak P (1973) Impingement heat transfer from turbulent air stream jets to flat plates: a literature survey, NASA TM X-2778

Maurel S, Solliec C (2001) A turbulent plane jet impinging nearby and from a flat plate. Exp Fluids 31:687–696

Ashfort-Frost S, Jambunathan K, Whithney CF (1997) Heat transfer from a flat plate to a turbulent axisymmetric impinging jet. Proc Inst Mech Eng 211:167–172

Fitzgerald JA, Garimella SV (1998) A study of the flow field of a confined and submerged impinging jet. Int J Heat Mass Transfer 41:1025–1034

Chuang SH (1989) Numerical simulation of an impinging jet on a flat plate. Int J Numer Fluids 9:1413–1426

Zhou DW, Lee SJ (2004) Heat transfer enhancement of impinging jets using mesh screens. Int J Heat Mass Transfer 47:2097–2108

Acknowledgements

This work was sponsored by the Turkey-State Planning Organization (DPT) under Grant No.2003.200.200.5.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Baydar, E., Ozmen, Y. An experimental investigation on flow structures of confined and unconfined impinging air jets. Heat Mass Transfer 42, 338–346 (2006). https://doi.org/10.1007/s00231-005-0021-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-005-0021-6