Abstract

Theoretical and experimental study of the paper drying process are presented. A mathematical model developed for combined heat ad mass transfer analysis of paper drying is given for both impinging air jets and through air drying methods. In this model, it is simply assumed that during the drying period of the paper has porous media and on the drying surface the vapour pressure of the evaporating liquid remains at a quasi-saturated value corresponding to the temperature of the liquid. The calculated transient paper temperatures in both methods agree well with the experimental results.

Similar content being viewed by others

Abbreviations

- A s :

-

surface area (m2)

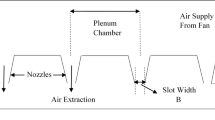

- B :

-

slot (nozzle) width (mm)

- C :

-

concentration (kg/m3)

- c p :

-

specific heat (J/kgK)

- D :

-

diffusion coefficient (m2/s)

- h fg :

-

enthalpy of evaporation (J/kg)

- h :

-

heat transfer coefficient (W/m2K)

- k c :

-

mass transfer coefficient (m/s)

- L :

-

distance from stagnation point (m)

- Le:

-

Lewis number (k/ρ cpD)

- M :

-

molecular weight (kg/kmol)

- m :

-

mass (kg)

- \(\dot m_{\text{b}} \) :

-

the rate of evaporation (kg/s)

- \(\dot m_{\text{D}} \) :

-

mass transfer rate (kg/s)

- Nu:

-

Nusselt number (hB/k)

- P:

-

pressure (N/m2)

- Ru:

-

universal gas constant (J/kgK)

- Re:

-

Reynolds number (vAB/ν)

- T :

-

temperature (°C)

- t :

-

time (s)

- V :

-

volume (m3)

- v :

-

air velocity (m/s)

- υ :

-

kinematic viscosity (m2/s)

- ρ:

-

density (kg/m3)

- θ:

-

temperature difference (°C)

- \(\dot Q\) :

-

rate of energy transfer (W)

- x :

-

moisture content (%)

- A:

-

drying air

- s:

-

surface

- E:

-

nozzle exit

- -:

-

average value

References

de Beer J, Worrell E, Blok K (1998) Long-term energy efficiency improvements in the paper and board industry. Energy 23:21–42

Mujumdar AS (1981) Recent developments in drying. Annual Conference of the Indian Institute of Chemical Engineering, Madras

Kudra T, Mujumdar AS (2002) Advanced drying technologies, Marcel Dekker, New York

Dreshfield AC (1957) The mechanism of hot-surface drying of fibrous sheets. Chem Eng Prog 53:174–180

Han ST (1964) Heat and mass transfer in hot-surface drying of fibre mats. In: Canadian pulp and paper association of international symposium on water removal at Presses and Dryers, pp T537–T549

Daane RA, Han ST (1961) An analysis of air-impingement drying. TAPPI 44:73–80

Polat S (1993) Heat and mass transfer in impingement drying. Drying Technology 11:1147–1176

Bond JF, Mujumdar AS, Heiningen ARP, Douglas WJM (1994) Drying paper by impinging jets of superheated steam. Part 2: Comparison of steam and air as drying fluids. Can J Chem Eng 72:452–456

Chen G, Gomes VG, Douglas WJM (1995) Impingement drying of paper. Drying Technology 13:1331–1344

Murugesan K, Seetharamu KN, Aswatha Narayana PA (1996) A one-dimensional analysis of convective drying of porous materials. Heat Mass Transfer 32:81–88

Bernada P, Bruneau D (1997) Drying of a paper coating: experimental study and modelling. Drying Technol 15:2061–2087

Chen G, Douglas WJM (1997) Through drying of paper. Drying Technol 15:295–314

Yu Z, Nilsson L, Karlsson T, Stanstrom S (1998) Convective paper drying-merits and limitations of evaporation front modelling. In: Drying‘98 Proceedings of 11th international drying symposium, Halkidiki, B:1629–1636

Malashenko A, Timofeev O, Karlsson M, Heikkila P, Edelmann K (1998) Further advances in paper drying. In: Drying’98 Proceedings of 11th international drying symposium, Halkidiki, B:1554–1562

Watzl A, Ruckert M (1998) Industrial through-air drying of nonwovens and paper: basic principles and applications. Drying Technol 16:1027–1045

Lehtinen J (1998) Condebelt board and paper drying. Drying Technol 16:1047–1073

Reardon SA, Davis MR, Doe PE (1998) Friction, heat and mass transfer for paper drying. Int J Heat Mass Transfer 41:1313–1325

Ramaswamy S, Holm RA (1999) Analysis of heat and mass transfer during drying of paper/board. Drying Technol 17:49–72

Sherwood TK (1929) The drying of solids-Part 1. Int Eng Chem 21:12

Avcı A, Can M, Etemoglu AB (2001) A theoretical approach to the drying process of thin film layers. Appl Thermal Eng 21:465–479

Etemoglu AB, Ulcay Y, Can M, Avcı A (2003) Mathematical modelling of combined diffusion of heat and mass transfer through fabrics. J Textile Inst (submitted)

Etemoglu AB (2003) Mathematical modelling of simultaneous heat and mass transfer in heterogeneous materials, PhD Thesis, University of Uludag

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Etemoglu, A.B., Can, M., Avcı, A. et al. Theoretical study of combined heat and mass transfer process during paper drying. Heat Mass Transfer 41, 419–427 (2005). https://doi.org/10.1007/s00231-004-0538-0

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-004-0538-0