Abstract

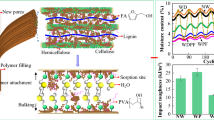

Wood–polymer composites (WPC) are commonly prepared by the impregnation and polymerization of active monomers in wood matrix. Due to the inferior interfacial compatibility between wood matrix and hydrophobic polymer interface, the treatment method could not significantly improve the dimensional stability of wood and make full use of the properties of polymer. In this study, a two-step approach was proposed to overcome this problem. The interface bonding between hydrophobic polymer and wood matrix was significantly improved by the formation of covalent bonds. The anti-swelling efficiency (65%), modulus of rupture (120.1 MPa), modulus of elasticity (10.9 GPa) and compressive strength (103.6 MPa) of the wood–polystyrene composites were superior to the wood treated with styrene alone.

Similar content being viewed by others

References

Brown NR, Frazier CE (2005) Synthesis of labeled acrylamide and N-methylolacrylamide (NMA): 15N-acrylamide, 13C-NMA, 15N-NMA, and 13C,15N-NMA. J Label Compd Radiopharm 48:1031–1039. https://doi.org/10.1002/jlcr.1015

Cabane E, Keplinger T, Merk V, Hass P, Burgert I (2014) Renewable and functional wood materials by grafting polymerization within cell walls. Chemsuschem 7:1020–1025. https://doi.org/10.1002/cssc.201301107

Chang HT, Chang ST (2002) Moisture excluding efficiency and dimensional stability of wood improved by acylation. Biores Technol 85:201–204. https://doi.org/10.1016/S0960-8524(02)00085-8

Che W, Xiao Z, Han G, Zheng Z, Xie Y (2018) Radiata pine wood treatment with a dispersion of aqueous styrene/acrylic acid copolymer. Holzforschung 72:387–396. https://doi.org/10.1515/hf-2017-0142

Chen GC (1994) Fungal decay resistance of wood reacted with chlorosulfonyl isocyanate or epichlorohydrin. Holzforschung 48:181–185. https://doi.org/10.1515/hfsg.1994.48.3.181

Cherry R, Manalo A, Karunasena W, Stringer G (2019) Out-of-grade sawn pine: a state-of-the-art review on challenges and new opportunities in cross laminated timber (CLT). Constr Build Mater 211:858–868. https://doi.org/10.1016/j.conbuildmat.2019.03.293

Devi RR, Ali I, Maji TK (2003) Chemical modification of rubber wood with styrene in combination with a crosslinker: Effect on dimensional stability and strength property. Biores Technol 88:185–188. https://doi.org/10.1016/S0960-8524(03)00003-8

Dong X, Zhuo X, Wei J, Zhang G, Li Y (2017) Wood-Based nanocomposite derived by in situ formation of organic-inorganic hybrid polymer within wood via a sol-gel method. ACS Appl Mater Interfaces 9:9070–9078. https://doi.org/10.1021/acsami.7b01174

Dong Y, Zhang W, Hughes MK et al (2019) Various polymeric monomers derived from renewable rosin for the modification of fast-growing poplar wood. Compos B Eng 174:106902. https://doi.org/10.1016/j.compositesb.2019.106902

Dong Y, Wang K, Li J, Zhang S, Shi SQ (2020a) Environmentally benign wood modifications: a review. ACS Sustain Chem Eng 8:3532–3540. https://doi.org/10.1021/acssuschemeng.0c00342

Dong Y, Altgen M, Mäkelä M et al (2020b) Improvement of interfacial interaction in impregnated wood via grafting methyl methacrylate onto wood cell walls. Holzforschung. https://doi.org/10.1515/hf-2019-0144

Ermeydan MA, Cabane E, Masic A, Koetz J, Burgert I (2012) Flavonoid insertion into cell walls improves wood properties. ACS Appl Mater Interfaces 4:5782–5789. https://doi.org/10.1021/am301266k

Ermeydan MA, Cabane E, Gierlinger N, Koetz J, Burgert I (2014a) Improvement of wood material properties via in situ polymerization of styrene into tosylated cell walls. RSC Adv 4:12981–12988. https://doi.org/10.1039/c4ra00741g

Ermeydan MA, Cabane E, Hass P, Koetz J, Burgert I (2014b) Fully biodegradable modification of wood for improvement of dimensional stability and water absorption properties by poly(ε-caprolactone) grafting into the cell walls. Green Chem 16:3313–3321. https://doi.org/10.1039/c4gc00194j

Gabrielli CP, Kamke FA (2010) Phenol-formaldehyde impregnation of densified wood for improved dimensional stability. Wood Sci Technol 44:95–104. https://doi.org/10.1007/s00226-009-0253-6

Gardon JL (1961) A quantitative study of crosslinking cotton with N-methylol acrylamide. J Appl Polym Sci 5:734–751. https://doi.org/10.1002/app.1961.070051816

Gierlinger N, Keplinger T, Harrington M (2012) Imaging of plant cell walls by confocal Raman microscopy. Nat Protoc 7:1694–1708. https://doi.org/10.1038/nprot.2012.092

Han X, Wang Z, Zhang Q, Pu J (2020) An effective technique for constructing wood composite with superior dimensional stability. Holzforschung 74:435–443. https://doi.org/10.1515/hf-2019-0176

Hemström K, Mahapatra K, Gustavsson L (2011) Perceptions, attitudes and interest of Swedish architects towards the use of wood frames in multi-storey buildings. Resour Conserv Recycl 55:1013–1021. https://doi.org/10.1016/j.resconrec.2011.05.012

Hill CAS (2006) Wood Modification: Chemical Thermal and Other Processes. Wiley, Chichester, UK

Hill CAS, Jones D (1999) Dimensional changes in Corsican pine sapwood due to chemical modification with linear chain anhydrides. Holzforschung 53:267–271. https://doi.org/10.1515/HF.1999.045

Hill DJT, O’Donnell JH, Pomery PJ, Whittaker MR (1995) A high resolution NMR investigation into the microstructure of HEMA and EEMA copolymers. Polym Gels Networks 3:85–97. https://doi.org/10.1016/0966-7822(94)00024-2

Huang Y, Li G, Chu F (2019) In situ polymerization of 2-hydroxyethyl methacrylate (HEMA) and 3-(methacryloxy)propyltrimethoxysilane (MAPTES) in poplar cell wall to enhance its dimensional stability. Holzforschung 73:469–474. https://doi.org/10.1515/hf-2018-0139

Islam MS, Hamdan S, Jusoh I, Rahman MdR, Talib ZA (2011) Dimensional stability and dynamic Youngs modulus of tropical light hardwood chemically treated with methyl methacrylate in combination with hexamethylene diisocyanate cross-linker. Ind Eng Chem Res 50:3900–3906. https://doi.org/10.1021/ie1021859

Jeremic D, Cooper P, Brodersen P (2007) Penetration of poly(ethylene glycol) into wood cell walls of red pine. Holzforschung 61:272–278. https://doi.org/10.1515/HF.2007.068

Kamel M, Amin SA, Kharaldy EA (1976) Creation of reactive centres on cotton. VII 17:2725–2738. https://doi.org/10.1177/004051757504500515

Keplinger T, Cabane E, Chanana M, Hass P, Merk V, Gierlinger N, Burgert I (2015) A versatile strategy for grafting polymers to wood cell walls. Acta Biomater 11:256–263. https://doi.org/10.1016/j.actbio.2014.09.016

Kurt R, Tomak ED (2019) The effect of DMDHEU modification on physical and biological properties of parallel strand lumbers. Constr Build Mater 195:497–504. https://doi.org/10.1016/j.conbuildmat.2018.11.064

Li Y, Dong X, Lu Z, Jia WD, Liu YX (2013a) Effect of polymer in situ synthesized from methyl methacrylate and styrene on the morphology, thermal behavior, and durability of wood. J Appl Polym Sci 128:13–20. https://doi.org/10.1002/app.38099

Li Y, Liu Z, Dong X, Fu Y, Liu Y (2013b) Comparison of decay resistance of wood and wood-polymer composite prepared by in-situ polymerization of monomers. Int Biodeterior Biodegradation 84:401–406. https://doi.org/10.1016/j.ibiod.2012.03.013

Li W, Wang H, Ren D, Yu YS, Yu Y (2015) Wood modification with furfuryl alcohol catalysed by a new composite acidic catalyst. Wood Sci Technol 49:845–856. https://doi.org/10.1007/s00226-015-0721-0

Liu W, Xie T, Qiu R, Fan M (2015) N-methylol acrylamide grafting bamboo fibers and their composites. Compos Sci Technol 117:100–106. https://doi.org/10.1016/j.compscitech.2015.06.005

Olaniran SO, Michen B, Mora Mendez DF et al (2019) Mechanical behaviour of chemically modified Norway spruce (Picea abies L. Karst.): experimental mechanical studies on spruce wood after methacrylation and in situ polymerization of styrene. Wood Sci Technol 53:425–445. https://doi.org/10.1007/s00226-019-01080-5

Qiu H, Yang S, Han Y et al (2018) Improvement of the performance of plantation wood by grafting water-soluble vinyl monomers onto cell walls. ACS Sustain Chem Eng 6:14450–14459. https://doi.org/10.1021/acssuschemeng.8b03112

Sathre R, Gustavsson L (2006) Energy and carbon balances of wood cascade chains. Resour Conserv Recycl 47:332–355. https://doi.org/10.1016/j.resconrec.2005.12.008

Sun W, Shen H, Cao J (2016) Modification of wood by glutaraldehyde and poly (vinyl alcohol). Mater Des 96:392–400. https://doi.org/10.1016/j.matdes.2016.02.044

Thybring EE, Piqueras S, Tarmian A, Burgert I (2020) Water accessibility to hydroxyls confined in solid wood cell walls. Cellulose 27:5617–5627. https://doi.org/10.1007/s10570-020-03182-x

Wang K, Dong Y, Yan Y, Zhang S, Li J (2018) Improving dimensional stability and durability of wood polymer composites by grafting polystyrene onto wood cell walls. Polym Compos 39:119–125. https://doi.org/10.1002/pc.23912

Xie Y, Fu Q, Wang Q, Xiao Z, Militz H (2013) Effects of chemical modification on the mechanical properties of wood. Eur J Wood Prod 71:401–416. https://doi.org/10.1007/s00107-013-0693-4

Xiong B, Zhao P, Cai P, Zhang L, Hu K, Cheng G (2013) NMR spectroscopic studies on the mechanism of cellulose dissolution in alkali solutions. Cellulose 20:613–621. https://doi.org/10.1007/s10570-013-9869-7

Yang Z, Cao L, Li J, Lin J, Wang J (2018) Facile synthesis of Cu-BDC/Poly(N-methylol acrylamide) HIPE monoliths via CO2-in-water emulsion stabilized by metal-organic framework. Polymer 153:17–23. https://doi.org/10.1016/j.polymer.2018.07.085

Yang T, Cao J, Ma E (2019a) How does delignification influence the furfurylation of wood? Ind Crops Prod 135:91–98. https://doi.org/10.1016/j.indcrop.2019.04.019

Yuan J, Hu Y, Li L, Cheng F (2013) The mechanical strength change of wood modified with DMDHEU. BioResources 8(1):1076–1088. https://doi.org/10.15376/biores.8.1.1076-1088

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (No. 31890772).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have declared that no conflict of interest exists.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Guo, D., Shen, X., Fu, F. et al. Improving physical properties of wood–polymer composites by building stable interface structure between swelled cell walls and hydrophobic polymer. Wood Sci Technol 55, 1401–1417 (2021). https://doi.org/10.1007/s00226-021-01317-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00226-021-01317-2