Abstract

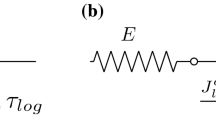

In this paper, the creep and relaxation behaviors of Xuan paper during the stretching process were studied. The results indicated that Burgers model could describe the creep behavior of Xuan paper perfectly including elastic deformation, viscoelastic deformation and plastic deformation. For the total creep, elastic strain, viscoelastic strain and plastic strain accounted for 62–78, 17–25, and 4–13 %, respectively. At a certain temperature and humidity, elastic strain, viscoelastic strain and plastic strain increased with the increase in stress in the range of 0.2–0.8σ max, and the proportion of viscoelastic and plastic strain increased, but the proportion of elastic strain decreased. Further, the proportion of each strain tended to be stable at last. A five-element Maxwell model could describe the relaxation of Xuan paper effectively. There were few influences on the parameters of five-element Maxwell model by strain levels, so these parameters could be regarded as material constants.

Similar content being viewed by others

References

Acha B, Reboredo MM, Marcovich NE (2007) Creep and dynamic mechanical behavior of PP-jute composites: effect of the interfacial adhesion. Compos A Appl Sci Manuf 38:1507–1516

Alfthan J (2005) Linear constitutive model for mechano-sorptive creep in paper. Int J Solids Struct 42:6261–6276

Amino Y (2005) Bamboo–precocious wood composite beams: bending capacity for long-term loading. J Bamboo Rattan 4(1):55–70

Cai Q, Hu K (2001) Creep failure of paper sheet in the constant tensile loads. Trans China Pulp Pap 16(2):91–95

Chen Y (1985) The property of paper (translation). China Light Industry Press, Beijing

DeMaio A, Patterson T (2004) The role of bonding on the tensile creep behavior of paper. In: Proceedings of the 2004 progress in paper physics seminar. Trondheim, Norway, pp 41–42

Dinwoodie JM (1981) Creep in chipboard Part 3: initial assessment of the influence of moisture content and level of stressing on rate of creep and time to failure. Wood Sci Technol 15:125–144

Jiménez L, Pérez I, de la Torre MJ, García JC (2000) Influence of process variables on the properties of pulp and paper sheets obtained by sulphite pulping of Olive tree wood. Wood Sci Technol 34:135–149

Lee S-Y, Yang H-S (2004) Creep behavior and manufacturing parameters of wood fiber filled polypropylene composites. Compos Struct 65:459–469

Li D (1998) A preliminary study of bending creep of Italy Poplar. J Sichuan Agric Univ 16(1):99–101

Luner P (1988) Evaluation of paper permanence. Wood Sci Technol 22:81–97

Ma D, He P, Xu Z (1999) Polymer structure and performance. Science Press, Beijing

Ma J, Yang D, Gong F (2005) The application of computer in chemistry and chemical engineering. High Education Press, Beijing

Nunez AJ, Marcovich NE, Aranguren MI (2004) Analysis of the creep behavior of polypropylene–woodflour composites. Polym Eng Sci 44(8):1594–1603

Olsson A-M, Salmén L (2014) Mechano-sorptive creep in pulp fibres and paper. Wood Sci Technol 48:569–580

Park BD, Balatinez JJ (1998) Short term flexural creep behavior of wood–fiber/polypropylene composites. Polym Compos 19(4):377–382

Sakurai N (1991) Cell wall functions in growth and development—a physical and chemical point of view. Bot Mag Tokyo 104:235–251

Schiffmann KI (2006) Nanoindentation creep and stress and relaxation tests of polycarbonate: analysis of viscoelastic properties by different rheological models. Int J Mater Res 97(9):1199–1211

Schniewind AP, Barrett JD (1972) Wood as a linear orthotropic viscoelastic material. Wood Sci Technol 6:43–57

Shao Z (2002) Application of variation coefficients Maxwell body to fit the creep of MDF. China Wood Industry 16(3):9–11

Shao Z (2003) The study on variable coefficients rheological model of wood. Scientia Silvae Sinicae 39(3):106–110

Shao Z (2005) The variable parameter rheological model of wood. Wood Sci Technol 39:19–26

Uesaka T, Murakami K, Imamura R (1980) Two-dimensional linear viscoelasticity of paper. Wood Sci Technol 14:131–142

Wang P (1987a) The rheological behaviour of poplar wood in compression perpendicular to grain I. Viscoelasticity. Scientia Silvae Sinicae 23(2):182–184

Wang P (1987b) The rheological behaviour of poplar wood in compression perpendicular to grain II. Plasticity. Scientia Silvae Sinicae 23(3):356–362

Wilding MA, Ward IM (1981) Creep and recovery of ultra high modulus polyethylene. Polymer 22:870–876

Yakushev PN, Peschanskaya NN (1975) Creep rate variability in gel–spun polyethylene. Polym Eng Sci 15(3):1286–1293

Acknowledgments

The study was supported by National Natural Science Foundation of China (No. 11008250).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gao, H., Wang, F. & Shao, Z. Study on the rheological model of Xuan paper. Wood Sci Technol 50, 427–440 (2016). https://doi.org/10.1007/s00226-015-0781-1

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00226-015-0781-1