Abstract

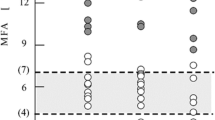

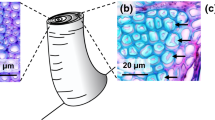

Tension wood, when kiln-dried, is likely to deform hugely, which is probably caused by a gelatinous layer of the gelatinous fiber. To elucidate the mechanism behind the deformation of tension wood during kiln-drying, the strains experienced by tension wood during a hygrothermal treatment that is akin to an early stage of kiln-drying were investigated. Normal wood elongated along the longitudinal axis after the first treatment and leveled off with repetitive treatments. During the first treatment, tension wood contracted significantly along the longitudinal axis, followed by small subsequent contractions, which occurred during successive treatments. This characteristic hygrothermal behavior of tension wood correlated with the areal ratio of the gelatinous layer. One of the possible reasons why tension wood behaves differently was thought to be particular behavior of gelatinous layer. This finding will contribute to the development of appropriate seasoning method for tension wood by clarifying the mechanism behind the deformation of the gelatinous layer.

Similar content being viewed by others

References

Abe K, Yamamoto H (2007) The influences of boiling and drying treatment on the behaviors of tension wood with gelatinous layers in Zelkova serrata. J Wood Sci 53:5–10

Bardet S, Gril J, Kojiro K (2012) Thermal strain of green Hinoki wood: separating the hygrothermal recovery and the reversible deformation. In: Frémond, M., Maceri, F (eds) Lecture notes in applied and computational mechanics, vol 61, mechanics, models and methods in civil engineering. Springer, Berlin. pp 157–162

Borrega M, Niemelä K, Sixta H (2013) Effect of hydrothermal treatment intensity on the formation of degradation products from birchwood. Holzforschung 67:871–879

Cave ID (1966) Theory of X-ray measurement of microfibril angle. For Prod J 16:37–42

Cave ID (1972) A theory of shrinkage of wood. Wood Sci Technol 6:284–292

Chang S, Clair B, Ruelle J, Beaucheˆne J, Di Renzo F, Quignard F, Zhao G, Yamamoto H, Gril J (2009) Mesoporosity as a new parameter for understanding tension stress generation in trees. J Exp Bot 60:3023–3030

Clair B (2012) Evidence that release of internal stress contributes to drying strains of wood. Holzforschung 66:349–353

Clair B, Thibaut B (2001) Shrinkage of the gelatinous layer of poplar and beech tension wood. IAWA J 22:121–131

Clair B, Gril J, Di Renzo F, Yamamoto H, Quignard F (2008) Characterization of gel in the cell wall to elucidate the paradoxical shrinkage of tension wood. Biomacromolecules 9:494–498

Forest Resources Assessment Report (2010) www.fao.org/docrep/013/i1757e/i1757e.pdf, FAO

Goring DAI (1963) Thermal softening of lignin, hemicellulose and cellulose. Pulp Pap Mag Can 64:T517–T527

Gril J, Thibaut B (1994) Tree mechanics and wood mechanics: relating hygrothermal recovery of green wood to the maturation process. Ann Sci For 51:329–338

Gril J, Berrada E, Thibaut B, Martin G (1993a) Recouvrance hygrothermique du bois vert. I. Influence de la température. Cas du jujubier (Ziziphus lotus (L) Lam) (hygrothermal recovery of green wood. I. Influence of temperature.). Ann Sci For 50:57–70 (in French)

Gril J, Berrada E, Thibaut B (1993b) Recouvrance hygrothermique du bois vert. II. Variations dans le plan transverse chez le Châtaignie et l’Epicéa et modélisation de lafissuration à coeur induite par l’é tuvage (hygrothermal recovery of green wood. II. Transverse variations in chestnut and spruce and modelling of the steaming-induced heart checking.). Ann Sci For 50:487–508 (in French)

Kübler H (1959) Studies of growth stresses in trees Part 3. Effect of heat treatment on the dimensions of green wood. Holz Roh-Werkst 17:77–86 (in German)

Meylen BA (1968) Cause of high longitudinal shrinkage of wood. For Prod J 18:75–78

Placet V, Passard J, Perre P (2007) Viscoelastic properties of green wood across the grain measured by harmonic tests in the range 0–95 C: hardwood versus softwood and normal wood versus reaction wood. Holzforschung 61:548–557

Sasaki Y, Okuyama T (1983) Residual stress and dimensional change on heating green wood. Mokuzai Gakkaishi 29:302–307

Sharma SN, Bali BI, Lohani RC (1978) Abnormal dimensional changes on heating green sal (Shorea robusta). Wood Sci 10:142–150

Skaar C (1988) Wood-water relations. Springer, Berlin

Tanaka M, Yamamoto H, Kojima M, Yoshida M, Matsuo M, Abubakar ML, Hongo I, Arizono T (2014) The interrelation between microfibril angle (MFA) and hygrothermal recovery (HTR) in compression wood and normal wood of Sugi and Agathis. Holzforschung 68:823–830

Tanaka M, Yamamoto H, Yoshida M, Matsuo M, Abubakar ML (2015) Retarded recovery of remaining growth stress in Agathis wood specimen caused by drying and subsequent re-swelling treatments. Euro J Wood Prod 73:289–298

Tejada A, Okuyama T, Yamamoto H, Yoshida M, Imai T, Itoh T (1998) Studies on the softening point of wood powder as a basis for understanding the release of residual growth stress in logs. For Prod J 48:84–90

Toba K, Yamamoto H, Yoshida M (2013) Micromechanical detection of growth stress in wood cell wall by wide angle X-ray diffraction (WAX). Holzforschung 67:315–323

Yamamoto H, Okuyama T, Yoshida M (1993) Method of determining the mean microfibril angle of wood over wide range by the improved Cave’s method. Mokuzai Gakkaishi 39:375–381

Yamamoto H, Sassus F, Ninomiya M, Grill J (2001) A model of anisotropic swelling and shrinking process of wood (part 2). Wood Sci Technol 35:167–181

Yamamoto H, Abe K, Arakawa Y, Okuyama T, Gril J (2005) Role of gelatinous layer (G-layer) on the origin of the physical properties of Acer sieboldianum. J Wood Sci 51:222–233

Yamamoto H, Ruelle J, Arakawa Y, Yoshida M, Clair B, Gril J (2010) Origin of the characteristic hygro-mechanical properties of the gelatinous layer in tension wood from Kunugi oak (Quercus acutissima). Wood Sci Technol 44:149–163

Yokota T, Tarkow H (1962) Changes in dimension on heating green wood. For Prod J 12:43–45

Acknowledgments

We are much obliged to the staffs of Northern Agriculture and Forestry Research Center in Laos, Aichi Forestry Research Institute in Japan, and the experimental forest of Nagoya university, for their cooperation during our field work. We are thankful to Dr. Joseph Gril of CNRS, University of Montpellier, France, for his valuable advice during manuscript preparation.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sujan, K., Yamamoto, H., Matsuo, M. et al. Continuum contraction of tension wood fiber induced by repetitive hygrothermal treatment. Wood Sci Technol 49, 1157–1169 (2015). https://doi.org/10.1007/s00226-015-0762-4

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00226-015-0762-4