Abstract

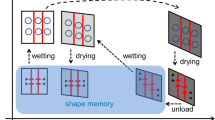

The dominant feature of artificial smart materials is the “shape memory” effect. This phenomenon is based on frozen strains (FS). They were detected in wood fastened specimens during drying in the early 1960s. The integral law of wood deforming under loading and moisture content and/or temperature changes was subsequently formulated. This law takes into account the forming of FS. It was applied for the calculation of wood drying stresses. Stress memory and strain memory effects for wood were discovered. Wood has the ability to recollect the type of loading (tension or compression) which it had undergone. The difference between the free and restrained shrinkage is named “frozen shrinkage” (FSh). In calculations of drying stresses, it is more justified to use the FSh concept than “mechano-sorptive creep” (MSC). The MSC phenomenon is observed at cyclical change of moisture content in loaded wood. “Hygrofatigue” that reduces wood stiffness plays the main role in this process.

Similar content being viewed by others

References

Abrahamson ER, Lake MS, Munshi NA, Gall K (2002) Shape memory polymers for elastic memory composites. In: Proceedings of 43rd structures, structural dynamics and material conference; American Institute of Aeronautics and Astronautics, 22–25 April 2002 Denver, Colorado, pp 1–11

Armstrong LD, Kingston RST (1960) Effect of moisture changes on deformation of wood under stress. Nature 185:862–863

Bažant ZP (1985) Constitutive equation of wood at variable humidity and temperature. Wood Sci Technol 19:159–177

Björkman A (2004) Wood science 1920–2003? In: Proceedings of IAWS meeting. Effects of fiber wall chemistry and structure on the utilization of wood. 4–9 August 2003, Cesis, Latvia, pp 42–52

Chulitsky NN (1938) Research of internal stresses in wood. IAM of USSR, Gosoboronizdat Moscow 13:3–16 (in Russian)

Erickson RW (1997) A summary of mechano-sorptive research at Kaufert Laboratory, University of Minnesota Proceedings of 2nd RCCWS international symposium “Wood structure, properties and quality”, Moscow, Russia, pp 30–37

Fujita S (1982) Tensile creep of wood during drying: I. Progress of shrinkage in wood under tensile load perpendicular to grain. Bull Fac Agric Kagoshima Univ 32:167–171

Gall K, Dunn ML (2004) Internal stress storage in shape memory polymer nanocomposites. Appl Phys Lett 85(2):290–292

Gorbacheva GA (2000) The method of experimental study of thermomechanical strains at bending. Proc MSFU 312:12–15 (in Russian)

Grossman P (1976) Requirements for model that exhibits mechano-sorptive behavior. Wood Sci Technol 10(3):163–168

Hanhijärvi A, Hunt D (1998) Experimental indication of interaction between viscoelastic and mechano-sorptive creep. Wood Sci Technol 32:57–70

Hill IL, Lessard RA (1986) Automated kiln drying system of third kind. Forest Products Research Society, pp 104–114

Hunt D, Gril J (1996) Evidence of physical ageing phenomenon in wood. J Mater Sci Lett 15:80–82

Lendlein A, Kelch S (2002) Shape memory polymers. Angew Chem Int Ed 41:2034–2057

McMillan IM (1955) Drying stresses in red oak. For Prod J 5(10):71–76

Mirianon F, Fortino S, Toratti T (2008) A method to model wood by using ABAQUS finite element software. Part 1. Constitutive model and computational details Espoo. VTT Publications 687, 51 p

Molinski W, Raczkowski J (1986) Mechano-sorptive creep of wood. In: Proceedings of II symposium “Issues of material creep”, Bialystok, Poland, pp 299–304

Moren T (1993) Creep, deformation and moisture redistribution during air convective wood drying and conditioning: Doctoral thesis, Lulea University of technology, Sweden, 116 D

Muzsynski L, Lagana R, Shaler SM (2003) An optical method for characterization of basic hygromechanical properties of solid wood in tension. In: Proceedings of 8th international IUFRO wood drying conference, 24–29 August 2003 Brasov, Romania, pp 77–82

Ohsako Y, Takahashi A, Yamada T (1968) Studies on the drying set of wood. II. The effects of tensile stresses on shrinkage of wood. Mokuzai Gakkaishi 14(1):24–31

Pang S (2005) Development, validation and practical application of mathematical models for wood drying. In: Proceedings of 9th international IUFRO wood drying conference, August 21–26, 2005, Nanjing, China, pp 39–49

Passard J, Perré P (2001) Creep test under water-saturated conditions: do the anisotropy ratios of wood change with temperature and time dependency. In: Proceedings of 7th international IUFRO wood drying conference, 9–13 July 2001 Tsukuba, Japan, pp 230–237

Ranta-Maunus A (1989) Analysis of drying stresses in timber. Pap Timber 10:1120–1122

Siskind RD (2008) Model development for shape memory polymers. PhD Thesis. Department of Applied Mathematics, North Carolina State University

Svensson S, Toratti T (2002) Mechanical response of wood perpendicular to grain when subjected to changes of humidity. Wood Sci Technol 36:145–156

Takemura T (1973) The memory effect of wood and stress development during drying. J Soc Mater Sci Jpn 22(236):476–478

Toratti T, Svensson S (2000) Mechano-sorptive experiments perpendicular to grain under tensile and compressive loads. Wood Sci Technol 34:317–326

Trebula P (1981) Linear differential shrinkage and stresses in spruce wood at drying. Drev vysk 26(3–4):41–52

Ugolev BN (1952) On the method of measuring residual stresses in wood. Zavod Lab 18(12):1505–1509 (in Russian)

Ugolev BN (1959) Internal stresses in wood at drying, Goslesbumizdat, Moscow-Leningrad (in Russian; translated into English by US Department of commerce, Clearinghouse for Fed. Sci. and Info., 1969)

Ugolev BN (1961) Method of research of wood rheological properties at changing moisture content. Zavod Lab 27(2):199–203 (In Russian)

Ugolev BN (1971) Deformability of wood and stress at drying. Lesn. Prom, Moscow (in Russian)

Ugolev BN (1976) General laws of wood deformation and rheological properties of hardwood. Wood Sci Technol 10(3):169–181

Ugolev BN (1986) Effect of “freezing” wood deformations at complex force and heat actions. In: Proceedings of 2nd international symposium on wood rheology, Rydzina, Poland, pp 5–14

Ugolev BN (1992) Wood deformability and drying stress. Tutorial. In: Proceedings of 3rd international IUFRO wood drying conference, August 18–21, 1992 Vienna, Austria, pp 11–17

Ugolev BN (1997) Strains and stresses: key problem in effective wood drying. In: Proceedings of IUFRO of all division 5 conference “Forest products for sustainable forestry”, 07.-12.07.1997 Washington State University, Pullman, USA, p 143

Ugolev BN (2005) Wood drying strains. Honorary report. In: Procedings of 9th International IUFRO wood drying conference, August 21–26, 2005, Nanjing, Chine, pp 13–23

Ugolev BN (2006) Frozen strains of wood as natural intelligent material. In: Proceedings of 5th IUFRO symposium “wood structure and properties”, Zvolen, Slovakia, pp 423–426

Ugolev BN, Galkin VP (2008) Effect of loading on wood shrinkage. MSFU Mosc 342:4–8 (in Russian)

Ugolev BN, Lapshin JG (1971) On deforming of wood when loaded in the condition of drying. Lesn Zhurnal 3:63–65 (in Russian)

Ugolev BN, Skuratov NV (1988) The elaboration of hygro-thermal treatment schedules at lumber kiln drying. MFTI Mosc 202:30–33 (in Russian)

Ugolev BN, Skuratov NV (1992) Stress-strain state of wood at kiln drying. Wood Sci Technol 26(3):209–217

Ugolev BN, Skuratov NV (1995) Wood hygrofatigue and its influence on strength and stiffness of dried lumber. Drev vysk 40(4):11–22

Ugolev BN, Lapshin JG, Krotov EV (1980) Measuring and monitoring of stresses at drying. Lesn. Prom, Moscow (in Russian)

Ugolev BN, Gorbacheva GA, Galkin VP, Aksenov PA (2004) Technological aspects of wood deformative conversions. In: Proceedings of 4th international RCCWS symposium “wood structure, properties and quality”, October 13–16, 2004 S.-Petersburg, Russia, pp 539–543

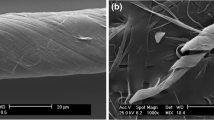

Ugolev BN, Gorbacheva GA, Galkin VP, Aksenov PA, Bazhenov AV (2007) Change of wood nanostructure at hygromechanical strains. MSFU Mosc 338:9–16 (in Russian)

Ugolev BN, Gorbacheva GA, Galkin VP, Kalinina AA (2009) Effect of moisture content cycles and loading on wood strains. MSFU Mosc 345:15–24 (in Russian)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ugolev, B.N. Wood as a natural smart material. Wood Sci Technol 48, 553–568 (2014). https://doi.org/10.1007/s00226-013-0611-2

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00226-013-0611-2