Abstract

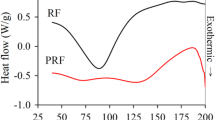

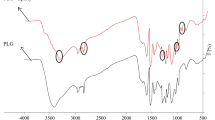

Cryptomeria japonica (Japanese cedar) wood was liquefied using polyethylene glycol (PEG-400 and PEG-600)/glycerol as the solvent with H2SO4 as a catalyst. The blended epoxy resins were prepared by mixing the liquefied wood with epoxy resin of various weight ratios and used for wood gluing. The results showed that blended epoxy resins could cure under room temperature with an exothermic reaction. DSC thermoanalysis showed that increasing the blending amount of liquefied wood would shift the peak of curing reaction to a higher temperature but with less heat released. Blended epoxy resins had a good dry bonding strength for wood when cured at room temperature. However, curing with heat treatment could improve the wet bonding strength of blended epoxy resins, especially for those prepared with PEG-400-liquefied wood.

Similar content being viewed by others

References

Alma MH, Shiraishi N (1998) Preparation of polyurethane-like foams from NaOH-catalyzed liquefied wood. Holz Roh-Werkst 56:245–246

Asano T, Kobayashi M, Tomita B, Kajiyama M (2007) Synthesis and properties of liquefied products of ozone treated wood/epoxy resins having high wood contents. Holzforschung 61:14–18

Kishi H, Fujita A, Miyazaki H, Matsuda S, Murakami A (2006) Synthesis of wood-based epoxy resins and their mechanical and adhesive properties. J Appl Polym Sci 102:2285–2292

Kobayashi M, Tukamoto K, Tomita B (2000) Application of liquefied wood to a new resin system-synthesis and properties of liquefied wood/epoxy resins. Holzforschung 54:93–97

Kobayashi M, Hatano Y, Tomita B (2001) Viscoelastic properties of liquefied wood/epoxy resin and its bond strength. Holzforschung 55:667–671

Kobayashi M, Asano T, Kajiyama M, Tomita B (2004) Analysis on residue formation during wood liquefaction with polyhydric alcohol. J Wood Sci 50:407–414

Kurimoto Y, Doi S, Tamura Y (1999) Species effects on wood-liquefaction in polyhydric alcohols. Holzforschung 53:617–622

Kurimoto Y, Takeda M, Koizumi A, Yamauchi S, Doi S, Tamura Y (2000) Mechanical properties of polyurethane films prepared from liquefied wood with polymeric MDI. Bioresour Technol 74:151–157

Kurimoto Y, Koizumi A, Doi S, Tamura Y, Ono H (2001) Wood species effects on the characteristics of liquefied wood and the properties of polyurethane films prepared from the liquefied wood. Biomass Bioenerg 21:381–390

Lee WJ, Chang CF (2003) Studies on the liquefaction using polyethylene glycol—China fir and Taiwan acacia. For Prod Ind 22:205–214

Lee WJ, Lin MS (2008) Preparation and application of polyurethane adhesives made from polyhydric alcohol liquefied Taiwan acacia and China fir. J Appl Polym Sci 109:23–31

Shiraishi N, Onodera S, Ohtani M, Masumoto T (1985) Dissolution of etherified or esterified wood into polyhydric alcohols or bisphenol A and their application in preparing wooden polymeric materials. Mokuzai Gakkaishi 31:418–420

Wu CC, Lee WJ (2008a) Gluability of polyblend resins prepared from polyhydric alcohol liquefied ma bamboo with epoxy resin. For Pro Ind 27:31–40

Wu CC, Lee WJ (2008b) Effects of the dosage of amine hardener on the curing property and adhesion performance of bisphenol A type epoxy resin. Q J Chin For 41:121–133

Xie T, Chen F (2005) Fast liquefaction of bagasse in ethylene carbonate and preparation of epoxy resin from the liquefied product. J Appl Polym Sci 98:1961–1968

Yamada T, Ono H (1999) Rapid liquefaction of lignocellulosic waste by using ethylene carbonate. Bioresour Technol 70:61–67

Yao Y, Yoshioka M, Shiraishi N (1994) Soluble properties of liquefied biomass prepared in organic solvents. I. The soluble behavior of liquefied biomass in various diluents. Mokuzai Gakkaishi 40:176–184

Yao Y, Yoshioka M, Shiraishi N (1995) Rigid polyurethane foams from combined liquefaction mixtures of wood and starch. Mokuzai Gakkaishi 41:659–668

Yao Y, Yoshioka M, Shiraishi N (1996) Water-absorbing polyurethane foam from liquefied starch. J Appl Polym Sci 60:1939–1949

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wu, CC., Lee, WJ. Curing behavior and adhesion properties of epoxy resin blended with polyhydric alcohol-liquefied Cryptomeria japonica wood. Wood Sci Technol 45, 559–571 (2011). https://doi.org/10.1007/s00226-010-0358-y

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00226-010-0358-y