Abstract

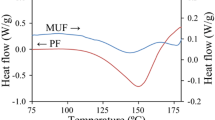

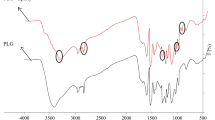

The effect of addition of Acacia mangium bark powder on the thermosetting processes of two commercial phenol resins, PF-A and PF-B, was examined by bond strength test, torsional braid analysis, and differential scanning calorimetry. When the bark powder was added to PF-A, the bond strength of plywood pressed at 110°C increased and was comparable to that of plywood pressed at 120 and 130°C. However, when the bark powder was added to PF-B, the bond strength of plywood pressed at 110°C was still lower than that of plywood pressed at 120 and 130°C. The relative rigidity and loss tangent of PF-A cured with the bark powder obtained by heating at 100°C were comparable to those at 120 and 140°C, and the reaction enthalpy was increased by bark powder addition. In contrast, chemical reactions for cured PF-B were not enhanced by bark powder addition.

Similar content being viewed by others

References

Hamada R, Ikeda S, Satake Y (1969) Utilization of wood bark for plywood adhesive. I. Effect of addition of bark of Acacia mollissima on the properties of phenol formaldehyde resin (in Japanese). Mokuzai Gakkaishi 15:165–170

Holopainen T, Alvila L, Rainio J, Pakkanen TT (1997) Phenol-formaldehyde resol resins studied by 13C-NMR spectroscopy, gel permeation chromatography, and differential scanning calorimetry. J Appl Polym Sci 66:1183–1193

JIS K 6833 (1994) General testing methods for adhesives. Japanese Standards Association (JSA), Tokyo

Kenny JM, Pisaniello G, Farina F, Puzziello S (1995) Calorimetric analysis of the polymerization reaction of a phenolic resin. Thermochim Acta 269/270:201–211

King PW, Mitchell RH, Westwood AR (1974) Structural analysis of phenolic resole resins. J Appl Polym Sci 18:1117–1130

Kissinger H (1957) Reaction kinetics in differential thermal analysis. Anal Chem 29:1702–1706

Lippmaa H, Samoson A (1988) Solid-state 13C NMR study of cured resorcinol-formaldehyde resins. J Adhes Soc Jpn 24:300–306

McCoy JPA (1918) US Patent 1269627

Ogawa S, Susanti CME, Yano H (2002) Direct utilization of Acacia mangium bark as water proof adhesives. In: Proceedings of the fourth international wood science symposium, Serpong, Indonesia, pp 182–187

Park B-D, Riedl B, Hsu EW, Shields J (1998) Effects of weight average molecular mass of phenol-formaldehyde adhesives on medium density fiberboard performance. Holz Roh Werkst 56:155–161

Park B-D, Riedl B, Bae H-J, Kim YS (1999) Differential scanning calorimetry of phenol-formaldehyde (PF) adhesives. J Wood Chem Technol 19:265–286

Philips EK, Detlefsen WD, Carlson FE (1991) Techniques for bonding high moisture content wood in oriented strand board with phenol–formaldehyde resin. In: Maloney TM (ed) Proceedings, 25th international particleboard/composite materials symposium, Washington, pp 231–248

Pizzi A (1983) Tannin-based wood adhesives. In: Pizzi A (ed) Wood adhesives chemistry and technology. Marcel Dekker, New York, pp 177–246

Rossouw DT, Pizzi A, McGillivray G (1980) The kinetics of condensation of phenolic polyflavonoid tannins with aldehydes. J Polym Sci Polym Chem Ed 18:3323–3343

Vázquez G, González-Álvarez J, López-Suevos F, Freire S, Antorrena G (2002) Curing kinetics of tannin-phenol-formaldehyde adhesives as determined by DSC. J Therm Anal Calorim 70:19–28

Werstler DD (1986) Quantitative 13C n.m.r. characterization of aqueous formaldehyde resins: 1. Phenol-formaldehyde resins. Polymer 27:750–756

Yano H, Ogawa S, Kawai S, Inai A, Homma Y, Yamauchi H, Nasu H, Yamazaki M, Yada G (2005) Manufacturing and utilization for wood adhesives of Acacia mangium bark powder (in Japanese). Mokuzai-kogyo 60:478–482

Yazaki Y, Collins PJ (1998) A novel tannin extraction from radiata pine bark for high quality wood adhesives. In: Proceedings of the fourth Pacific rim bio-based composites symposium, Bogor, Indonesia, pp 19–26

Yazaki Y, Hill WE (1980) Molecular size distribution of radiata pine bark extracts and its effect on properties. Holzforschung 34:125–130

Yazaki Y, Morita S, Collins PJ (1998) Potential use of Acacia mangium bark for waterproof wood adhesives. In: Proceedings of the fourth Pacific rim bio-based composites symposium, Bogor, Indonesia, pp 36–44

Acknowledgments

We express our sincere gratitude to Koshii & Co. Ltd. for providing the A. mangium bark powder. We also thank Professor Tsuda, Asahikawa National College of Technology, for his support during the NMR measurements and Mr. Yoshida, Hokkaido Industrial Research Institute, for his support during the DSC measurements.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Miyazaki, J., Hirabayashi, Y. Effect of the addition of Acacia mangium bark on thermosetting of phenol–formaldehyde resin. Wood Sci Technol 45, 449–460 (2011). https://doi.org/10.1007/s00226-010-0342-6

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00226-010-0342-6