Abstract

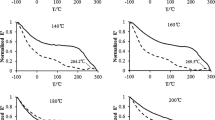

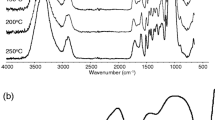

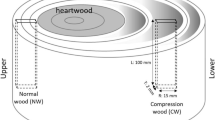

In order to understand the reason why glycerin pre-treatment can accelerate the deformation fixation of compressed wood, the interaction between glycerin and wood at various temperatures was investigated in this study from stress relaxation approach. The compression stress relaxation curves of poplar (Populus cathayana Rehd.) samples impregnated with glycerin were measured at temperatures ranging from 25 to 180°C, together with the curves of oven-dry wood at temperatures between 100 and 180°C for comparison. The activation energy was calculated according to the Eyring’s absolute rate reaction theory. The results showed that temperature had very obvious effect on stress relaxation for both glycerin-treated wood (GTW) and oven-dry wood. The stress released very fast at higher temperatures. Glycerin showed an accelerating effect on stress relaxation. At temperatures exceeding 120°C, a complete relaxation of the stress could be expected. While for untreated wood, it cannot be reached until 160°C. By calculating the apparent activation energy (ΔE) of GTW at different temperatures, it is clear that two mechanisms are responsible for different temperature ranges. From 40 to 100°C, ΔE is only 8.24 kJ/mol, which corresponds to the hydrogen bonds formed between wood and glycerin molecules; from 120 to 180°C, ΔE reached 81.38 kJ/mol, which corresponds to the degradation of hemicelluloses or lignin, and during this process, new cross-linking would happen.

Similar content being viewed by others

References

Dwianto W, Morooka T, Norimoto M (1998) The compressive stress relaxation of Albizia (Paraserienthes falcata Becker) wood during heat treatment. Mokuzai Gakkaishi 44(6):403–409

Dwianto W, Morooka T, Norimoto M, Kitajima T (1999) Stress relaxation of Sugi (Cryptomeria japonica D.Don) wood in radial compression under high temperature steam. Holzforschung 53(5):541–546

Fukuta S, Takasu Y, Sasaki Y, Hirashima Y (2007) Compressive deformation process of Japanese cedar (Cryptomeria japonica). Wood Fiber Sci 39(4):548–555

Glasstone S, Laidler KJ, Eyring H (1941) The theory of rate processes. McGraw Hill, New York, pp 544–551

Higashihara T, Morooka T, Norimoto M (2001) Permanent fixation of transversely compressed wood by heating and its mechanism. Mokuzai Gakkaishi 47(3):205–211

Iida I, Norimoto M (1987) Recovery of compression set. Mokuzai Gakkaishi 33(12):929–933

Iida I, Norimoto M, Imamura Y (1984) Hygrothermal recovery of compression set. Mokuzai Gakkaishi 30(5):354–358

Inoue M, Norimoto M, Otsuka Y, Yamada T (1991a) Surface compression of coniferous wood lumber II: Permanent set of compression wood by low molecular weight phenolic resin and some physical properties of the products. Mokuzai Gakkaishi 37(3):223–227

Inoue M, Norimoto M, Otsuka Y, Yamada T (1991b) Surface compression of coniferous wood lumber III: Permanent set of the surface compressed layer by a water solution of low molecular weight phenolic resin. Mokuzai Gakkaishi 37(3):234–240

Inoue M, Minato K, Norimoto M (1994) Permanent fixation of compressive deformation of wood by crosslinking. Mokuzai Gakkaishi 40(9):931–936

Inoue M, Hamaguchi T, Morooka T, Higashihara T (2000) Fixation of compressive deformation of wood by wet heating under atmospheric pressure. Mokuzai Gakkaishi 46(4):298–304

Inoue M, Sekino N, Morooka T, Rowell RM, Norimoto M (2008) Fixation of compressive deformation in wood by pre-steaming. J Trop For Sci 20(4):273–281

Ito Y, Tanahashi M, Shigematsu M, Shinoda Y (1998) Compressive-molding of wood by high-pressure steam-treatment: Part 2. Mechanism of permanent fixation. Holzforschung 52(2):217–221

Kuriyama A (1967) On the changes in the chemical composition of wood within the temperature range up to 200°C. Materials 16(169):772–776

Stamm AJ (1964) Wood and cellulose science. Ronald Press, New York

Toshimi H (1995) Kinetics of pyrolysis of wood and cellulose. Mokuzai Gakkaishi 41(10):879–886

Acknowledgments

This study was supported by the National Natural Science Foundation of China (NSFC) (No. 30500386).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yan, L., Cao, J., Gao, W. et al. Interaction between glycerin and wood at various temperatures from stress relaxation approach. Wood Sci Technol 45, 215–222 (2011). https://doi.org/10.1007/s00226-010-0322-x

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00226-010-0322-x