Abstract

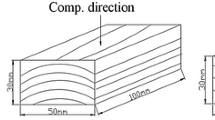

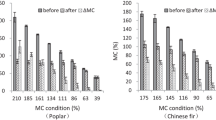

The drying kinetics of reaction woods in Picea abies (compression wood) and Fagus sylvatica (tension wood) in comparison with their corresponding normal woods was investigated under constant convective drying conditions. Moisture profiles along the thickness of small flat-sawn boards taken from reaction and opposite wood zones were evaluated using a polychromatic X-ray system, a non-destructive method. The results revealed substantial differences in the drying behavior between the reaction and opposite woods. Both reaction woods represented slower drying rate than their matching normal woods mainly during the period of free water loss. However, the reaction and opposite woods reached the final moisture content (MC) of about 12% at the same time due to higher initial MC in the opposite woods. In the case of reaction wood, it took a longer time for the moisture profile to become approximately uniform. Overall, a more striking difference was observed in the drying behavior of compression and opposite wood in P. abies. Some important anatomical differences like the cell and pit dimensions and their proportion give some explanations for these drying behaviors.

Similar content being viewed by others

References

Badia MA, Mothe F, Constant T, Nepveu G (2005) Assessment of tension wood detection based on shiny appearance for three poplar cultivars. Ann For Sci 62:43–49

Baettig R, Rémond R, Perré P (2006) Measuring moisture content profiles in a board during drying: a polychromatic x-ray system interfaced with a vacuum/pressure laboratory kiln. Wood Sci Technol 4:261–274

Clair B, Thibaut B (2001) Shrinkage of the gelatinous layer of poplar and beech tension wood. IAWA J 22:121–131

Cunderlik I, Kudela J, Molinski W (1992) Reaction beech wood in drying process. In: IUFRO drying conference, Vienna, pp 350–353

Davis CP, Carrington CG, Sun ZF (2002) The influence of compression wood on the drying curves of Pinus radiata in dehumifier conditions. Dry Technol 20:2005–2026

Donaldson LA, Grace J, Downes GM (2004) Within-tree variation in anatomical properties of compression wood in radiata pine. IAWA J 25:253–271

Harris JM (1977) Shrinkage and density of radiata pine compression wood in relation to its anatomy and mode of formation. N Z J For Sci 7:91–106

Hillis WE, Evans R, Washusen R (2004) An unusual formation of tension wood in a natural forest Acacia sp. Holzforschung 58:241–245

Jourez B, Riboux A, Leclecrcq A (2001) Comparison of basic density and longitudinal shrinkage in tension wood and opposite wood in young stems of Populous euramericana cv. Ghoy when subjected to a gravitational stimulus. Can J For Res 31:1676–1683

Ladell JL, Carmichael AJ, Thomas GHS (1968) Current work in Ontario on compression wood in black spruce in relation to pulp yield and quality. In: Proceedings of the eighth lake states forest tree improvement conference, Res. Pap. NC-23, U.S. Forest Service, North Central Forest Experiment Station, St. Paul, MN, pp 52–60

Öhman M (1998) Prediction of the properties of sawn timber by visual inspection of saw logs. Licentiate Thesis, Lulea University of Technology, ISSN 1402–1757

Öhman M (2001) The measurement of compression wood and other wood features and the prediction of their impact on wood products. Doctoral thesis, Lulea University of Technology, Division of Wood Technology, ISSN 1402–1544

Perré P (2007) Experimental device for the accurate determination of wood-water relations on micro-samples. Holzforschung 61:419–429

Perré P, Thiercelin F, Aguiar O (2000) Prototype high temperature/high pressure kiln for the evalution of wood drying schedules. Dry Technol 18:1849–1863

Timell TE (1986) Compression wood in gymnosperms, vol 1 and 3. Springer, Berlin

Warensjö M (2003) Compression wood in Scots pine and Norway spruce—distribution in relation to external geometry and the impact on the dimensional stability in sawn wood. Doctoral thesis, Swedish University of Agricultural Science, Department of Forest Products and Markets

Warensjö M, Rune G (2004) Effect of compression wood and grain angle on deformation of studs from 22-year-old Scots pine tree. Scand J For Res 19:48–54

Washusen R, Ades P, Vinden P (2001) Tension wood occurrence in Eucalyptus globules Labill, I. The spatial distribution of tension wood in one 11-year-old tree. Aust For 65:120–126

Washusen R, Ilic J, Waugh G (2003) The relationship between longitudinal growth strain and the occurrence of gelatinous fibers in 10- and 11-year-old Eucalyptus globulus Labill. Holz Roh Werkst 61:299–303

Williams DH (1971) A comparison of rates of drying of “compression” and “Normal” 4 in. by 1 in. P. radiate. N.Z For. Res. Inst. Forest Product Report No. 303

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tarmian, A., Remond, R., Faezipour, M. et al. Reaction wood drying kinetics: tension wood in Fagus sylvatica and compression wood in Picea abies . Wood Sci Technol 43, 113–130 (2009). https://doi.org/10.1007/s00226-008-0230-5

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00226-008-0230-5