Abstract

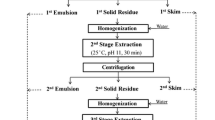

The effect of two different extraction methods (alkaline extraction isoelectric precipitation––AEIP and salt extraction dialysis––SE) on the production of protein isolates from four different pulse types grown in Canada (yellow pea-YP, green lentil-GL, chickpea-CH and navy bean-NB) were studied for their physicochemical, functional, and nutritional properties. The extraction method and type of pulse had an effect on protein and extraction yields. The method used for extraction had an influence on the surface properties as well as the functionality of the isolated proteins. SE-produced isolates presented higher solubility, foaming capacity and emulsion activity than those prepared through AEIP. Protein quality results showed that higher in-vitro protein digestibility (IVPD) and in-vitro protein digestibility corrected amino-acid scores (IV-PDCAAS) were achieved for proteins obtained through AEIP than those prepared for SE samples. The current study contributes to a better understanding of the effects of extraction methods on the resulting protein characteristics and properties of different pulses grown in Canada, which can impact their suitability for different product applications.

Similar content being viewed by others

Data availability

Data included in this manuscript will be made available upon request.

References

Stone AK, Nosworthy MG, Chiremba C, House JD, Nickerson MT (2019) A comparative study of the functionality and protein quality of a variety of legume and cereal flours. Cereal Chem 96:1159–1169. https://doi.org/10.1002/cche.10226

Singhal A, Karaca AC, Tyler R, Nickerson M (2016) Pulse proteins: from processing to structure-function relationships. Grain Legumes. InTech, USA

Stone AK, Karalash A, Tyler RT, Warkentin TD, Nickerson MT (2015) Functional attributes of pea protein isolates prepared using different extraction methods and cultivars. Food Res Int 76:31–38. https://doi.org/10.1016/j.foodres.2014.11.017

Chang L, Lan Y, Bandillo N, Ohm JB, Chen B, Rao J (2022) Plant proteins from green pea and chickpea: extraction, fractionation, structural characterization and functional properties. Food Hydrocoll 123:107165. https://doi.org/10.1016/j.foodhyd.2021.107165

Boye J, Zare F, Pletch A (2010) Pulse proteins: processing, characterization, functional properties and applications in food and feed. Food Res Int 43:414–431. https://doi.org/10.1016/j.foodres.2009.09.003

Chang YW, Alli I, Molina AT, Konishi Y, Boye J (2012) Isolation and characterization of chickpea (Cicer arietinum L.) seed protein fractions. Food Bioprocess Technol 5:618–625. https://doi.org/10.1007/s11947-009-0303-y

Tanger C, Engel J, Kulozik U (2020) Influence of extraction conditions on the conformational alteration of pea protein extracted from pea flour. Food Hydrocoll 107:105949. https://doi.org/10.1016/j.foodhyd.2020.105949

Hall C, Hillen C, Robinson JG (2017) Composition, nutritional value, and health benefits of pulses. Cereal Chem 94:11–31. https://doi.org/10.1094/cchem-03-16-0069-fi

Osemwota EC, Alashi AM, Aluko RE (2022) Physicochemical and functional properties of albumin, globulin and glutelin fractions of green lentil seed. Int J Food Sci Technol 57:3967–3981. https://doi.org/10.1111/ijfs.15608

Ghumman A, Kaur A, Singh N (2016) Functionality and digestibility of albumins and globulins from lentil and horse gram and their effect on starch rheology. Food Hydrocoll 61:843–850. https://doi.org/10.1016/j.foodhyd.2016.07.013

Karaca AC, Low N, Nickerson M (2011) Emulsifying properties of chickpea, faba bean, lentil and pea proteins produced by isoelectric precipitation and salt extraction. Food Res Int 44:2742–2750. https://doi.org/10.1016/j.foodres.2011.06.012

Carbas B, Machado N, Pathania S, Brites C, Rosa EAS, Barros AI (2021) Potential of legumes: nutritional value, bioactive properties, innovative food products, and application of eco-friendly tools for their assessment. Food Rev Int. https://doi.org/10.1080/87559129.2021.1901292

Sá AGA, Moreno YMF, Carciofi BAM (2020) Food processing for the improvement of plant proteins digestibility. Crit Rev Food Sci Nutr 60:3367–3386. https://doi.org/10.1080/10408398.2019.1688249

Kato A, Nakai S (1980) Hydrophobicity determined by a fluorescence probe method and its correlation with surface properties of proteins. Biochim Biophys Acta 624:13–20. https://doi.org/10.1016/0005-2795(80)90220-2

Laemmli UK (1970) Glycine-SDS-PAGE for separation of proteins. Nature 227:680–685

Konieczny D, Stone AK, Nosworthy MG, House JD, Korber DR, Nickerson MT, Tanaka T (2020) Nutritional properties of pea protein-enriched flour treated with different proteases to varying degrees of hydrolysis. Cereal Chem 97:429–440. https://doi.org/10.1002/cche.10258

Cacique AP, Barbosa ÉS, de Pinho GP, Silvério FO (2021) Miniaturized methodologies for determining the total phenol and flavonoid concentrations and the antioxidant activity. Food Anal Methods 14:1110–1120. https://doi.org/10.1007/s12161-020-01934-w

Morr CV, German B, Kinsella JE, Regenstein JM, Van Buren JP, Kilara A, Lewis BA, Mangino ME (1985) A Collaborative study to develop a standardized food protein solubility procedure. J Food Sci 50:1715–1718. https://doi.org/10.1111/j.1365-2621.1985.tb10572.x

Pearce KN, Kinsella JE (1978) Emulsifying properties of proteins: evaluation of a turbidimetric technique. J Agric Food Chem 26:716–723. https://doi.org/10.1021/jf60217a041

AOAC (2003) Official method of analysis, 17th edn. Association of official analytical chemists, Washington, DC

International Organization for Standardization (2016) Animal feeding stuffs—Determination of tryptophan, content ISO 13904, Geneva

Astephen N (2018) Waters AccQ Tag method for hydrolysate amino acid analysis. Retrieved from https://www.waters.com/waters/library.htm?locale=en_us&lid=1520760. Accesed 15 Dec 2022

FAO (2013) Dietary protein quality evaluation in human nutrition Report of an FAO Expert Consultation. FAO Food Nutr Pap 92:1–66

Hsu HW, Vavak DL, Satterlee LD, Miller GA (1977) A multienzyme technique for estimating protein digestibility. J Food Sci 42:1269–1273. https://doi.org/10.1111/j.1365-2621.1977.tb14476.x

Yang J, Zamani S, Liang L, Chen L (2021) Extraction methods significantly impact pea protein composition, structure and gelling properties. Food Hydrocoll 117:106678. https://doi.org/10.1016/j.foodhyd.2021.106678

Karaca AC, Low N, Nickerson M (2011) Emulsifying properties of canola and flaxseed protein isolates produced by isoelectric precipitation and salt extraction. Food Res Int 44:2991–2998. https://doi.org/10.1016/j.foodres.2011.07.009

Kohnhorst AL, Smith DM, Uebersax MA, Bennink MR (1991) Production and characterization of a protein concentrate from navy beans (phaseolus vulgaris). Food Chem. https://doi.org/10.1016/0308-8146(91)90129-c

Ozdal T, Capanoglu E, Altay F (2013) A review on protein–phenolic interactions and associated changes. Food Res Int 51:954–970. https://doi.org/10.1016/j.foodres.2013.02.009

Sęczyk Ł, Świeca M, Kapusta I, Gawlik-Dziki U (2019) Protein–phenolic interactions as a factor affecting the physicochemical properties of white bean proteins. Molecules 24:408. https://doi.org/10.3390/molecules24030408

Mondor M, Aksay S, Drolet H, Roufik S, Farnworth E, Boye JI (2009) Influence of processing on composition and antinutritional factors of chickpea protein concentrates produced by isoelectric precipitation and ultrafiltration. Innov Food Sci Emerg Technol 10:342–347. https://doi.org/10.1016/j.ifset.2009.01.007

Xu BJ, Chang SKC (2007) A Comparative Study on phenolic profiles and antioxidant activities of legumes as affected by extraction solvents. J Food Sci 72:S159–S166. https://doi.org/10.1111/j.1750-3841.2006.00260.x

Karaca AC, Nickerson MT, Low NH (2011) Lentil and chickpea protein-stabilized emulsions: optimization of emulsion formulation. J Agric Food Chem 59:13203–13211. https://doi.org/10.1021/jf203028n

Keivaninahr F, Gadkari P, Zoroufchi Benis K, Tulbek M, Ghosh S (2021) Prediction of emulsification behaviour of pea and faba bean protein concentrates and isolates from structure–functionality analysis. RSC Adv 11:12117–12135. https://doi.org/10.1039/dora09302e

Krause J-P, Schultz M, Dudek S (2002) Effect of extraction conditions on composition, surface activity and rheological properties of protein isolates from flaxseed (Linum usitativissimum L). J Sci Food Agric 82:970–976. https://doi.org/10.1002/jsfa.1140

Mertens C, Dehon L, Bourgeois A, Verhaeghe-Cartrysse C, Blecker C (2012) Agronomical factors influencing the legumin/vicilin ratio in pea ( pisum sativum L.) seeds. J Sci Food Agric 92:1591–1596. https://doi.org/10.1002/jsfa.4738

Guldiken B, Konieczny D, Wang N, Hou A, House JD, Tu K, Rosendahl S, Lavier M, Nickerson MT (2021) Effect of variety and environment on the physicochemical, functional, and nutritional properties of navy bean flours. Eur Food Res Technol 247:1745–1756. https://doi.org/10.1007/s00217-021-03745-7

Swanson BG (1990) Pea and lentil protein extraction and functionality. J Am Oil Chem Soc 67:276–280. https://doi.org/10.1007/bf02539676

Mundi S, Aluko RE (2012) Physicochemical and functional properties of kidney bean albumin and globulin protein fractions. Food Res Int 48:299–306. https://doi.org/10.1016/j.foodres.2012.04.006

Lam RSH, Nickerson MT (2013) Food proteins: a review on their emulsifying properties using a structure–function approach. Food Chem 141:975–984. https://doi.org/10.1016/j.foodchem.2013.04.038

McClements DJ, Lu J, Grossmann L (2022) Proposed methods for testing and comparing the emulsifying properties of proteins from animal, plant, and alternative sources. Colloids and Interfaces 6:19. https://doi.org/10.3390/colloids6020019

Damodaran S (2006) Protein stabilization of emulsions and foams. J Food Sci 70:R54–R66. https://doi.org/10.1111/j.1365-2621.2005.tb07150.x

Ma KK, Grossmann L, Nolden AA, McClements DJ, Kinchia AJ (2022) Functional performance of plant proteins. Foods 11:4. https://doi.org/10.3390/foods11040594

Martinez M, Stone AK, Yovchev AG, Peter R, Vandenberg A, Nickerson MT (2016) Effect of genotype and environment on the surface characteristics and functionality of air-classified faba bean protein concentrates. Eur Food Res Technol 242:1903–1911. https://doi.org/10.1007/s00217-016-2690-4

Shi D, Nickerson MT (2022) Comparative evaluation of the functionality of faba bean protein isolates with major legume proteins in the market. Cereal Chem 99:1246–1260. https://doi.org/10.1002/cche.10589

Toews R, Wang N (2013) Physicochemical and functional properties of protein concentrates from pulses. Food Res Int 52:445–451. https://doi.org/10.1016/j.foodres.2012.12.009

Nosworthy MG, House JD (2017) Factors influencing the quality of dietary proteins: implications for pulses. Cereal Chem J 94:49–57. https://doi.org/10.1094/cchem-04-16-0104-fi

Nosworthy MG, Neufeld J, Frohlich P, Young G, Malcolmson L, House JD (2017) Determination of the protein quality of cooked canadian pulses. Food Sci Nutr 5:896–903. https://doi.org/10.1002/fsn3.473

Nosworthy M, Medina G, Franczyk A, Neufeld J, Appah P, Utioh A, Frohlich P, House J (2018) Effect of processing on the in vitro and in vivo protein quality of beans (phaseolus vulgaris and vicia faba). Nutrients 10:671. https://doi.org/10.3390/nu10060671

Park SJ, Kim TW, Baik BK (2010) Relationship between proportion and composition of albumins, and in vitro protein digestibility of raw and cooked pea seeds ( Pisum sativum L.). J Sci Food Agric 90:1719–1725. https://doi.org/10.1002/jsfa.4007

Genovese MI, Lajolo FM (1996) In vitro digestibility of albumin proteins from phaseolus vulgaris L. Effect of Chemical Modification. J Agric Food Chem 44:3022–3028. https://doi.org/10.1021/jf9507304

Funding

The financial support for the present study was provided through Agriculture and Agri-Food Canada’s AgriScience Program (Canadian Pulse Science Research Cluster) under the Canadian Agricultural Partnership, the Saskatchewan Pulse Growers, the Alberta Pulse Growers, the Manitoba Pulse and Soybean Growers, and the Natural Sciences and Engineering Research Council of Canada Discovery grant program.

Author information

Authors and Affiliations

Contributions

FH contributed to the experimental design, collection and interpretation of the data, and drafting of the manuscript; JH measured amino acid profiles for all ingredients and edited the manuscript; whereas MN as the project leader contributed to the experimental design and editing of the final manuscript.

Corresponding author

Ethics declarations

Conflicts of interest

The authors have no conflict of interest to declare.

Ethical approval

The present article does not contain studies performed with humans or animals.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Higa, F., House, J.D. & Nickerson, M.T. Functionality and nutritional properties of yellow pea, green lentil, chickpea, and navy bean proteins extracted by different methods. Eur Food Res Technol 250, 273–286 (2024). https://doi.org/10.1007/s00217-023-04385-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-023-04385-9