Abstract

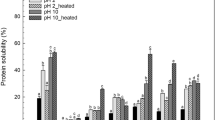

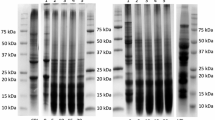

This research examined the physicochemical, functional, and nutritional aspects of pea (PPI) and faba bean protein isolates (FBPI) modified using trypsin at varying levels of hydrolysis. Enzyme hydrolysis decreased the protein content for both pulse protein isolates and increased the lipid content for pea. The surface charge became more negative, and the surface hydrophobicity was enhanced. The surface and interfacial tension, in general, decreased upon hydrolysis. The oil holding capacity for both pulses increased while the water holding capacity decreased. The foaming capacity of FBPI was significantly lowered by hydrolysis, while in the case of PPI, it increased at pH 4.5 and was unaffected at 7.0. The foaming stability increased for both pulses at pH 4.5 but was reduced at pH 7.0. At pH 4.5, hydrolysis enhanced the emulsion activity index of FBPI, while it decreased the index of PPI. The indices increased for both pulses at pH 7.0. The emulsion stability index was generally reduced for FBPI but improved for PPI after hydrolysis. All samples were limiting in tryptophan and the sulfur-containing amino acids, and in vitro protein digestibility decreased after hydrolysis for both pulses. As the results of these changes, overall protein quality improved for FBPI but not PPI. The degree of protein hydrolysis was an important factor in determining the functional and nutritional attributes of modified pulse proteins along with pH and pulse type.

Similar content being viewed by others

Data availability

Data can be made available upon request.

References

Amândio MST, Rocha JMS, Xavier AMRB (2023) Enzymatic hydrolysis strategies for cellulosic sugars production to obtain bioethanol from Eucalyptus globulus bark. Fermentation 9(3):241. https://doi.org/10.3390/fermentation9030241

Hou Y, Wu Z, Dai Z, Wang G, Wu G (2017) Protein hydrolysates in animal nutrition: industrial production, bioactive peptides, and functional significance. J Anim Sci Biotechnol 8(3):513–525. https://doi.org/10.1186/s40104-017-0153-9

Barać MB, Pešić MB, Stanojević SP, Kostić AZ, Čabrilo SB (2015) Techno-functional properties of pea (Pisum sativum) protein isolates: a review. Acta Period Technol 46:1–18. https://doi.org/10.2298/APT1546001B

Goertzen AD, Nickerson MT, Tanaka T (2021) The improvement of the functional properties of a chickpea protein isolate through proteolysis with three proteases. Cereal Chem 98(3):439–449. https://doi.org/10.1002/cche.10383

Konieczny D, Stone AK, Korber DR, Nickerson MT, Tanaka T (2020) Physicochemical properties of enzymatically modified pea protein-enriched flour treated by different enzymes to varying levels of hydrolysis. Cereal Chem 97(2):326–338. https://doi.org/10.1002/cche.10248

Martineau-Côté D, Achouri A, Karboune S, L’Hocine L (2022) Faba bean: an untapped source of quality plant proteins and bioactives. Nutrients 14(8):1–27. https://doi.org/10.3390/nu14081541

Le Gall M, Guéguen J, Séve B, Quillien L (2005) Effects of grinding and thermal treatments on hydrolysis susceptibility of pea proteins (Pisum sativum L.). J Agric Food Chem 53(8):3057–3064. https://doi.org/10.1021/jf040314w

Sim S, Akila SRV, Chiang J, Henry C (2021) Plant proteins for future foods: a roadmap. Foods 10(8):1967. https://doi.org/10.3390/foods10081967

Humiski LM, Aluko RE (2007) Physicochemical and bitterness properties of enzymatic pea protein hydrolysates. J Food Sci. https://doi.org/10.1111/j.1750-3841.2007.00475.x

Adler-Nissen J (1979) Determination of the degree of hydrolysis of food protein hydrolysates by trinitrobenzenesulfonic acid. J Agric Food Chem 27(6):1256–1262. https://doi.org/10.1021/jf60226a042

Avramenko N, Low N, Nickerson M (2013) The effects of limited enzymatic hydrolysis on the physicochemical and emulsifying properties of a lentil protein isolate. Food Res Int 51:162–169. https://doi.org/10.1016/j.foodres.2012.11.020

AOAC (2005) Official method of analysis of AOAC international, 18th edn. Association of Official Analytical Chemists, Gaithersburg

Das PP, Xu C, Lu Y, Khorsandi A, Tanaka T, Korber DR, Nickerson MT, Rajagopalan N (2023) Snapshot of proteomic changes in Aspergillus oryzae during various stages of fermentative processing of pea protein isolate. Food Chem Mol Sci 6:100169. https://doi.org/10.1016/j.fochms.2023.100169

Kato A, Nakai S (1980) Hydrophobicity determined by a fluorescence probe method and its correlation with surface properties of proteins. Biochim Biophys Acta BBA Protein Struct 624:13–20

Stone AK, Karalash A, Tyler RT, Warkentin TD, Nickerson MT (2015) Functional attributes of pea protein isolates prepared using different extraction methods and cultivars. Food Res Int 76:31–38. https://doi.org/10.1016/j.foodres.2014.11.017

Can Karaca A, Low N, Nickerson M (2011) Emulsifying properties of chickpea, faba bean, lentil and pea proteins produced by isoelectric precipitation and salt extraction. Food Res Int 44:2742–2750. https://doi.org/10.1016/j.foodres.2011.06.012

Wang Y, Ghosh S, Nickerson MT (2019) Effect of pH on the formation of electrostatic complexes between lentil protein isolate and a range of anionic polysaccharides, and their resulting emulsifying properties. Food Chem. 298:125023. https://doi.org/10.1016/j.foodchem.2019.125023

Achouri A, Boye JI, Yaylayan VA, Yeboah FK (2005) Functional properties of glycated soy 11S glycinin. Food Chem and Toxicol 70:269–274. https://doi.org/10.1111/j.1365-2621.2005.tb07172.x

Bradford MM (1976) A rapid and sensitive method for the quantification of microgram quantities of protein utilizing the principle of protein-dye binding. Anal Biochem 72(1–2):248–254. https://doi.org/10.1016/0003-2697(76)90527-3

Yin SW, Tang CH, Cao JS, Hu EK, Wen QB, Yang XQ (2008) Effect of limited enzymatic hydrolysis with trypsin on the functional properties of hemp (Cannabis sativa L.) protein isolate. Food Chem 106:1004–1013. https://doi.org/10.1016/j.foodchem.2007.07.030

Wilde PJ, Clark DC (1996) Methods of testing protein functionality. Blackie Academic and Professional, London

Pearce KN, Kinsella JE (1978) Emulsifying properties of proteins: evaluation of a turbidimetric technique. J Agric Food Chem 26(3):716–723. https://doi.org/10.1021/jf60217a041

FAO (Food and Agricultural Organization) (1991) The state of food and agriculture. http://www.fao.org/3/a-t0496e.pdf. Accessed 19 Jan 2023

Tinus T, Damour M, Van Riel V, Sopade PA (2012) Particle size-starch-protein digestibility relationships in cowpea (Vigna unguiculata). J Food Eng 113:254–264. https://doi.org/10.1016/j.jfoodeng.2012.05.041

García Arteaga V, Apéstegui Guardia M, Muranyi I, Eisner P, Schweiggert-Weisz U (2020) Effect of enzymatic hydrolysis on molecular weight distribution, techno-functional properties and sensory perception of pea protein isolates. Innov Food Sci Emerg Technol 65:102449

Bogdanov IV, Shenkarev ZO, Finkina EI, Melnikova DN, Rumynskiy EI, Arseniev AS, Ovchinnikova TV (2016) A novel lipid transfer protein from the pea Pisum sativum: Isolation, recombinant expression, solution structure, antifungal activity, lipid binding, and allergenic roperties. BMC Plant Biol 16(1):1–17. https://doi.org/10.1186/s12870-016-0792-6

Carbonaro M, Maselli P, Nucara A (2012) Relationship between digestibility and secondary structure of raw and thermally treated legume proteins: a Fourier transform infrared (FT-IR) spectroscopic study. Amino Acids 43(2):911–921. https://doi.org/10.1007/s00726-011-1151-4

Shevkani K, Singh N, Kaur A, Rana JC (2015) Structural and functional characterization of kidney bean and field pea protein isolates: a comparative study. Food Hydrocoll 43:679–689. https://doi.org/10.1016/j.foodhyd.2014.07.024

Bogahawaththa D, Bao Chau NH, Trivedi J, Dissanayake M, Vasiljevic T (2019) Impact of selected process parameters on solubility and heat stability of pea protein isolate. Food Sci Technol 102:246–253. https://doi.org/10.1016/j.lwt.2018.12.034

Shevkani K, Singh N, Chen Y, Kaur A, Yu L (2019) Pulse proteins: Secondary structure, functionality and applications. J Food Sci Technol 56(6):2787–2798. https://doi.org/10.1007/s13197-019-03723-8

Achouri A, Zhang W, Shiying X (1998) Enzymatic hydrolysis of soy protein isolate and effect of succinylation on the functional properties of resulting protein hydrolysates. Food Res Int 31(9):617–623. https://doi.org/10.1016/S0963-9969(98)00104-5

Eckert E, Han J, Swallow K, Tian Z, Jarpa-Parra M, Chen L (2019) Effects of enzymatic hydrolysis and ultrafiltration on physicochemical and functional properties of faba bean protein. Cereal Chem 96(4):725–741. https://doi.org/10.1002/cche.10169

Xu X, Liu W, Liu C, Luo L, Chen J, Luo S, McClements DJ, Wu L (2016) Effect of limited enzymatic hydrolysis on structure and emulsifying properties of rice glutelin. Food Hydrocoll 61:251–260. https://doi.org/10.1016/j.foodhyd.2016.05.023

Peng W, Kong X, Chen Y, Zhang C, Yang Y, Hua Y (2016) Effects of heat treatment on the emulsifying properties of pea proteins. Food Hydrocoll 52:301–310. https://doi.org/10.1016/j.foodhyd.2015.06.025

Liu C, Bhattarai M, Mikkonen KS, Heinonen M (2019) Effects of enzymatic hydrolysis of fava bean protein isolate by Alcalase on the physical and oxidative stability of oil-in-water emulsions. J Agric Food Chem 67(23):6625–6632. https://doi.org/10.1021/acs.jafc.9b00914

Yuan B, Ren J, Zhao M, Luo D, Gu L (2012) Effects of limited enzymatic hydrolysis with pepsin and high-pressure homogenization on the functional properties of soybean protein isolate. Food Sci Technol 46(2):453–459. https://doi.org/10.1016/j.lwt.2011.12.001

Wu WU, Hettiarachchy NS, Qi M (1998) Hydrophobicity, solubility, and emulsifying properties of soy protein peptides prepared by papain modification and ultrafiltration. J Am Oil Chem Soc 75(7):845–850. https://doi.org/10.1007/s11746-998-0235-0

Periago MJ, Vidal ML, Ros G, Rincón F, Martínez C, López G, Rodrigo J, Martínez I (1998) Influence of enzymatic treatment on the nutritional and functional properties of pea flour. Food Chem 63(1):71–78. https://doi.org/10.1016/S0308-8146(97)00199-4

Wani IA, Sogi DS, Shivhare US, Gill BS (2015) Physico-chemical and functional properties of native and hydrolyzed kidney bean (Phaseolus vulgaris L.) protein isolates. Food Res Int 76:11–18. https://doi.org/10.1016/j.foodres.2014.08.027

Malomo SA, Aluko RE (2015) A comparative study of the structural and functional properties of isolated hemp seed (Cannabis sativa L.) albumin and globulin fractions. Food Hydrocoll 43:743–752. https://doi.org/10.1016/j.foodhyd.2014.08.001

Vioque J, Sánchez-Vioque R, Clemente A, Pedroche J, Millán F (2000) Partially hydrolyzed rapeseed protein isolates with improved functional properties. J Am Oil Chem Soc 77(4):447–450. https://doi.org/10.1007/s11746-000-0072-y

Barać M, Čabrilo S, Pešić M, Stanojević S, Pavlićević M, Maćej O, Ristić N (2011) Functional properties of pea (Pisum sativum, L.) protein isolates modified with chymosin. Int J Mol Sci 12(12):8372–8387. https://doi.org/10.3390/ijms12128372

Samaei SP, Ghorbani M, Tagliazucchi D, Martini S, Gotti R, Themelis T, Tesini F, Gianotti A, Gallina Toschi T, Babini E (2020) Functional, nutritional, antioxidant, sensory properties and comparative peptidomic profile of faba bean (Vicia faba L.) seed protein hydrolysates and fortified apple juice. Food Chem 330:127120. https://doi.org/10.1016/j.foodchem.2020.127120

Walstra P, Vliet T (2008) Dispersed systems: Basic considerations. In: Damodaran S, Parkin KL, Fennema OR (eds) Fennema’s food chemistry. CRC Press, Boca Raton. https://doi.org/10.1201/9781420020526

Duc G (1997) Faba bean (Vicia faba L.). Field Crops Res 53(1–3):99–109. https://doi.org/10.1016/S0378-4290(97)00025-7

Nosworthy MG, Franczyk A, Zimoch-Korzycka A, Appah P, Utioh A, Neufeld J, House JD (2017) Impact of processing on the protein quality of pinto bean (Phaseolus vulgaris) and buckwheat (Fagopyrum esculentum Moench) flours and blends, as determined by in vitro and in vivo methodologies. J Agric Food Chem 65(19):3919–3925. https://doi.org/10.1021/acs.jafc.7b00697

Konieczny D, Stone AK, Nosworthy MG, House JD, Korber DR, Nickerson MT, Tanaka T (2020) Nutritional properties of pea protein-enriched flour treated with different proteases to varying degrees of hydrolysis. Cereal Chem 97(2):429–440. https://doi.org/10.1002/cche.102586

Shi D, House JD, Wanasundara JPD, Nickerson MT (2022) Comparative evaluation of the nutritional value of faba bean flours and protein isolates with major legumes in the market. Cereal Chem 99(5):1013–1029. https://doi.org/10.1002/cche.10575

Weerasooriya DK, Bean SR, Nugusu Y, Ioerger BP, Tesso TT (2018) The effect of genotype and traditional food processing methods on in-vitro protein digestibility and micronutrient profile of sorghum cooked products. PLoS ONE 13(9):1–22. https://doi.org/10.1371/journal.pone.0203005

Funding

Financial support for the present study was provided through Agriculture and Agri-Food Canada’s AgriScience Program (Canadian Pulse Science Research Cluster) under the Canadian Agricultural Partnership, the Saskatchewan Pulse Growers, the Alberta Pulse Growers, the Manitoba Pulse and Soybean Growers and the Natural Sciences and Engineering Research Council of Canada Discovery grant program. The authors gratefully acknowledge support from the Sustainable Protein Production (SPP) program of the National Research Council Canada and by the Aquatic and Crop Resource Development Research Centre as part of its contribution to the SPP program.

Author information

Authors and Affiliations

Contributions

Joy Sareen carried out the experiments, analyzed data, and wrote the first draft of the manuscript. Dai Shi and Andrea K. Stone provided critical review and editing of the draft. Caishuang Xu carried out CGE and SDS-PAGE experiments and data analysis. Brittany Polley carried out the trypsin inhibitor assay. James D. House, Pankaj Bhowmik, and Nandhakishore Rajagopalan provided technical assistance and comments on the draft. Takuji Tanaka and Michael T. Nickerson designed and supervised the research and revised the manuscript drafts. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors have no competing interests to declare that are relevant to the content of this article.

Compliance with ethics requirements

This article does not contain any studies with human participants or animal subjects.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sareen, J., Shi, D., Stone, A.K. et al. Effect of enzyme hydrolysis on the physicochemical, functional, and nutritional properties of pea and faba bean protein isolates. Eur Food Res Technol 249, 3175–3190 (2023). https://doi.org/10.1007/s00217-023-04358-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-023-04358-y