Abstract

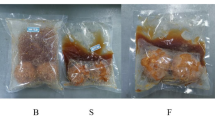

Volatile flavor profile of skim milk relates to product quality and consumer liking. The volatile compositions of different skim milk products are challenging to discriminate due to subtle constituents and inconspicuous peculiarities. This study develops a correlative analysis protocol for the characterization and differentiation of volatile flavor components in various skim milk products via headspace solid-phase micro-extraction gas chromatography–mass spectrometry (HS-SPME–GC–MS) and electronic nose (E-nose) with multivariate statistical analysis. Sixty-two volatile flavor components were identified in six skim milk products, which were paired into pasteurized skim milk, ultra-high-temperature skim milk, and modified skim milk, respectively. Distinguishable variation trends were observed upon the aroma response values of skim milk samples through the solid-state E-nose sensors. The results of principal component analysis, cluster heatmap analysis and Venn diagram analysis showed that significant distinctions in varying degrees among the six skim milk products could be presented in both volatile flavor composition and aroma release distribution. The correlative analysis by partial least squares regression indicated an adequate combination of HS-SPME–GC–MS and E-nose for the differentiation and classification of volatile flavor profiles in skim milk products. These findings provide an insightful perspective for the efficient flavor evaluation of fluid skim milk.

Similar content being viewed by others

Change history

16 April 2021

A Correction to this paper has been published: https://doi.org/10.1007/s00217-021-03749-3

References

Pereira PC (2014) Milk nutritional composition and its role in human health. Nutrition 30(6):619–627

Visioli F, Strata A (2014) Milk, dairy products, and their functional effects in humans: a narrative review of recent evidence. Adv Nutr 5(2):131–143

McCarthy K, Lopetcharat K, Drake M (2017) Milk fat threshold determination and the effect of milk fat content on consumer preference for fluid milk. J Dairy Sci 100(3):1702–1711

Toxqui L, Pérez-Granados AM, Blanco-Rojo R, Wright I, González-Vizcayno C, Vaquero MP (2013) Effects of an iron or iron and vitamin D-fortified flavored skim milk on iron metabolism: a randomized controlled double-blind trial in iron-deficient women. J Am Coll Nutr 32(5):312–320

Hausmann A, Sanciolo P, Vasiljevic T, Kulozik U, Duke M (2013) Performance assessment of membrane distillation for skim milk and whey processing. J Dairy Sci 97(1):56

Shanmugam A, Chandrapala J, Ashokkumar M (2012) The effect of ultrasound on the physical and functional properties of skim milk. Innov Food Sci Emerg Technol 16:251–258

Devi AF, Buckow R, Singh T, Hemar Y, Kasapis S (2015) Colour change and proteolysis of skim milk during high pressure thermal-processing. J Food Eng 147:102–110

Lubary M, Hofland GW, Ter Horst JH (2011) The potential of milk fat for the synthesis of valuable derivatives. Eur Food Res Technol 232(1):1–8

Pan M, Tong L, Chi X, Ai N, Cao Y, Sun B (2019) Comparison of sensory and electronic tongue analysis combined with HS-SPME–GC–MS in the evaluation of skim milk processed with different preheating treatments. Molecules 24(9):1650

Vazquez-Landaverde PA, Velazquez G, Torres JA, Qian MC (2005) Quantitative determination of thermally derived off-flavor compounds in milk using solid-phase microextraction and gas chromatography. J Dairy Sci 88(11):3764–3772

Dan T, Wang D, Jin R, Zhang H, Zhou T, Sun T (2017) Characterization of volatile compounds in fermented milk using solid-phase microextraction methods coupled with gas chromatography–mass spectrometry. J Dairy Sci 100(4):2488–2500

Ai N-S, Liu H-l, Wang J, Zhang X-M, Zhang H-J, Chen H-T, Huang M-Q, Liu Y-G, Zheng F-P, Sun B-G (2015) Triple-channel comparative analysis of volatile flavour composition in raw whole and skim milk via electronic nose, GC–MS and GC-O. Anal Methods 7(10):4278–4284

Qiu S, Wang J (2017) The prediction of food additives in the fruit juice based on electronic nose with chemometrics. Food Chem 230:208–214

Ampuero S, Bosset J (2003) The electronic nose applied to dairy products: a review. Sens Actuators B Chem 94(1):1–12

Zhu J, Chen F, Wang L, Niu Y, Xiao Z (2017) Evaluation of the synergism among volatile compounds in Oolong tea infusion by odour threshold with sensory analysis and E-nose. Food Chem 221:1484–1490

Rodriguez-Mendez ML, Apetrei C, Gay M, Medina-Plaza C, De Saja J, Vidal S, Aagaard O, Ugliano M, Wirth J, Cheynier V (2014) Evaluation of oxygen exposure levels and polyphenolic content of red wines using an electronic panel formed by an electronic nose and an electronic tongue. Food Chem 155:91–97

Cui S, Wu J, Wang J, Wang X (2017) Discrimination of American ginseng and Asian ginseng using electronic nose and gas chromatography–mass spectrometry coupled with chemometrics. J Ginseng Res 41(1):85–95

Tong L, Yi H, Wang J, Pan M, Chi X, Hao H, Ai N (2019) Effect of preheating treatment before defatting on the flavor quality of skim milk. Molecules 24(15):2824

Zhang X, Ai N, Wang J, Tong L, Zheng F, Sun B (2016) Lipase-catalyzed modification of the flavor profiles in recombined skim milk products by enriching the volatile components. J Dairy Sci 99(11):8665–8679

Zhang X, Ai N, Chen L, Sun B (2020) Lipase-catalyzed modification of structural properties and sensory profile of recombined skim milk: from a non-volatile perspective. LWT 118:108838

Vandendool H, Kratz PD (1963) A generalization of the retention index system including linear temperature programmed gas–liquid partition chromatography. J Chromatogr A 11(C):463–471

Campbell R, Drake M (2013) Invited review: The effect of native and nonnative enzymes on the flavor of dried dairy ingredients. J Dairy Sci 96(8):4773–4783

Kurtovic I, Marshall SN, Cleaver HL, Miller MR (2016) The use of immobilised digestive lipase from Chinook salmon (Oncorhynchus tshawytscha) to generate flavour compounds in milk. Food Chem 199:323–329

Rashid A, Javed I, Rasco B, Sablani S, Ayaz M, Ali MA, Abdullah M, Imran M, Gondal TA, Afzal MI (2019) Measurement of off-flavoring volatile compounds and microbial load as a probable marker for keeping quality of pasteurized milk. Appl Sci 9(5):959

Karatapanis AE, Badeka AV, Riganakos KA, Savvaidis IN, Kontominas MG (2006) Changes in flavour volatiles of whole pasteurized milk as affected by packaging material and storage time. Int Dairy J 16(7):750–761

Yeh E, Schiano A, Jo Y, Barbano D, Drake M (2017) The effect of vitamin concentrates on the flavor of pasteurized fluid milk. J Dairy Sci 100(6):4335–4348

Amador-Espejo GG, Gallardo-Chacón JJ, Juan B, Trujillo AJ (2017) Effect of ultra-high-pressure homogenization at moderate inlet temperatures on volatile profile of milk. J Food Process Eng 40(5):e12548. https://doi.org/10.1111/jfpe.12548

Jensen S, Jansson T, Eggers N, Clausen MR, Larsen LB, Jensen HB, Ray C, Sundgren A, Andersen HJ, Bertram HC (2015) Storage-induced changes in the sensory characteristics and volatiles of conventional and lactose-hydrolyzed UHT processed milk. Eur Food Res Technol 240(6):1247–1257

Toelstede S, Hofmann T (2008) Sensomics mapping and identification of the key bitter metabolites in Gouda cheese. J Agric Food Chem 56(8):2795

Holland R, Liu SQ, Crow VL, Delabre ML, Lubbers M, Bennett M, Norris G (2005) Esterases of lactic acid bacteria and cheese flavour: milk fat hydrolysis, alcoholysis and esterification. Int Dairy J 15(6–9):711–718

Valero E, Villamiel M, Miralles B, Sanz J, Martınez-Castro I (2001) Changes in flavour and volatile components during storage of whole and skimmed UHT milk. Food Chem 72(1):51–58

Vagenas G, Roussis IG (2012) Fat-derived volatiles of various products of cows’, ewes’, and goats’ milk. Int J Food Prop 15(3):665–682

Shiratsuchi H, Shimoda M, Imayoshi K, Noda K, Osajima Y (1994) Volatile flavor compounds in spray-dried skim milk powder. J Agric Food Chem 42(6):1323–1327

Licón CC, Mendoza JHD, Maggi L, Berruga MI, Aranda RMM, Carmona M (2012) Optimization of headspace sorptive extraction for the analysis of volatiles in pressed ewes’ milk cheese. Int Dairy J 23(1):53–61

Forss DA (1979) Mechanisms of formation of aroma compounds in milk and milk products. J Dairy Res 46:691

Buchin S, Delague V, Duboz G (1998) Influence of pasteurization and fat composition of milk on the volatile compounds and flavor characteristics of a semi-hard cheese. J Dairy Sci 81(12):3097–3108

Mahdieh IranmaneshHamid, EzzatpanahBehrouz H, Amir K, Torshizi, (2018) SPME/GC-MS characterization of volatile compounds of Iranian traditional dried Kashk. Int J Food Prop 21(1):1067–1079

Al-Attabi Z, D’Arcy BR, Deeth HC (2008) Volatile sulphur compounds in UHT milk. Crit Rev Food Sci Nutr 49(1):28–47. https://doi.org/10.1080/10408390701764187

Toso B, Procida G, Stefanon B (2002) Determination of volatile compounds in cows’ milk using headspace GC–MS. J Dairy Res 69(4):569–577

Faulkner H, O’Callaghan TF, McAuliffe S, Hennessy D, Stanton C, O’Sullivan MG, Kerry JP, Kilcawley KN (2018) Effect of different forage types on the volatile and sensory properties of bovine milk. J Dairy Sci 101(2):1034–1047

Jo Y, Carter B, Barbano D, Drake M (2019) Identification of the source of volatile sulfur compounds produced in milk during thermal processing. J Dairy Sci 102(10):8658–8669

Carter B, Patel H, Barbano DM, Drake M (2018) The effect of spray drying on the difference in flavor and functional properties of liquid and dried whey proteins, milk proteins, and micellar casein concentrates. J Dairy Sci 101(5):3900–3909

Feng T, Yang M, Ma B, Zhao Y, Zhuang H, Zhang J, Chen D (2021) Volatile profiles of two genotype Agaricus bisporus species at different growth stages. Food Res Int 140:109761. https://doi.org/10.1016/j.foodres.2020.109761

Wang H, Wang C, Guo M (2021) Impact of polymerized whey protein/pectin thickening (PP) system on physical properties and volatile compounds of goat milk kefir mild and kefir. J Food Sci 86:1014

Jo Y, Benoist D, Barbano D, Drake M (2018) Flavor and flavor chemistry differences among milks processed by high-temperature, short-time pasteurization or ultra-pasteurization. J Dairy Sci 101(5):3812–3828

Cheng Z, O’Sullivan M, Kerry J, Drake M, Miao S, Kaibo D, Kilcawley K (2020) A cross-cultural sensory analysis of skim powdered milk produced from pasture and non-pasture diets. Food Res Int 138:109749

Stewart A, Grandison A, Fagan C, Ryan A, Festring D, Parker JK (2018) Changes in the volatile profile of skim milk powder prepared under different processing conditions and the effect on the volatile flavor profile of model white chocolate. J Dairy Sci 101(10):8822–8836

Chung N, Jo Y, Joe MH, Jeong MH, Jeong YJ, Kwon JH (2017) Rice vinegars of different origins: discriminative characteristics based on solid-phase microextraction and gas chromatography with mass spectrometry, an electronic nose, electronic tongue and sensory evaluation. J Inst Brew 123(1):159–166

Tian H, Li F, Qin L, Yu H, Ma X (2015) Discrimination of chicken seasonings and beef seasonings using electronic nose and sensory evaluation. J Food Sci 79(11):S2346–S2353

Acknowledgements

This work was supported by a Grant from the National Natural Science Foundation of China (31801571) and the National Key Research and Development Program of China (no. 2016YFD0401104).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Compliance with ethics requirements

This article does not contain any studies with human or animal subjects.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Chi, X., Shao, Y., Pan, M. et al. Distinction of volatile flavor profiles in various skim milk products via HS-SPME–GC–MS and E-nose. Eur Food Res Technol 247, 1539–1551 (2021). https://doi.org/10.1007/s00217-021-03730-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-021-03730-0