Abstract

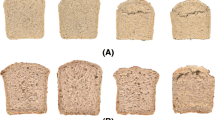

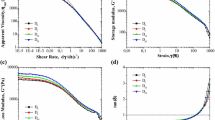

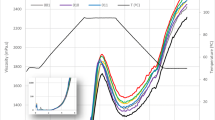

The impact of heat moisture treatment (HMT) on the thermoviscous, viscoelastic and mechanical properties of binary flour matrices (wheat:barley, 60:40, wt:wt) was investigated in untreated and HMT (15% moisture content, 1 h heating time at 120 °C) hydrated samples to assess the potential of HMT to modify dough viscoelasticity and doughmaking functionality in diluted breadmaking wheat matrices. HMT significance was tackled (a) in excess of water, by applying successive cooking and cooling cycles to hydrated samples (14%, w:w), determination of viscometric parameters, and subsequent determination of textural (compression test) and viscoelastic parameters (stress relaxation test) in pasted and gelled hydrated flours, and (b) under water restrictions by assessing the consistency (forward extrusion test), the primary and secondary mechanical properties (Texture Profile Analysis), and the viscoelastic behaviour (stress relaxation test) of untreated and HMT mixed doughs made at different flour hydration levels (63 and 70%). In highly hydrated blends, HMT barley flour provided enhanced viscosity patterns regardless of the presence of native or HMT wheat flour, and harder gels with larger initial stress to reach a defined deformation, particularly in the presence of HMT wheat flour. Under restricted water availability, doughs made at 70% hydration level when compared to their counterparts made at 63% explicited lower stress relaxation curves with higher values for both initial decay rate and extent of the decay, shorter relaxation times and higher percent of stress relaxation, giving softer and more cohesive doughs. The most elastic-like dough blends were those prepared with HMT wheat and barley flours at 63% hydration, while the most viscous-like doughs were those from native flours made at 70% hydration.

Similar content being viewed by others

Abbreviations

- a :

-

Greenness/redness

- b :

-

Blueness/yellowness

- CB−:

-

Native commercial barley flour

- CB:

-

Commercial barley

- CB+:

-

Commercial barley flour treated at 15% moisture for 1 h at 120 °C

- DY:

-

Dough yield

- F 0 :

-

Initial stress (g force, N)

- HMT:

-

Heat moisture treatment

- k 1 :

-

Constant related to stress decay rate (s)

- k 2 :

-

Constant related to residual stress at the end of the experiment

- L :

-

Lightness

- %SR:

-

Percent of stress relaxation

- RT:

-

Relaxation time (min)

- RVA:

-

Rapid visco analyser

- SP:

-

Swelling power (g/g)

- SRC:

-

Solvent retention capacity (%)

- WAI:

-

Water solubility index (% solids, flour, d. b.)

- WT−:

-

Native wheat flour

- WT:

-

Wheat

- WT+:

-

Wheat flour treated at 15% moisture for 1 h at 120 °C

- WT+ CB−:

-

Blend of wheat flour treated at 15% moisture for 1 h at 120 °C and native commercial barley flour, mixed at 60:40, wt:wt

- WT+ CB+:

-

Blend of wheat and commercial barley flours individually treated at 15% moisture for 1 h at 120 °C and mixed at 60:40, wt:wt

- WT− CB−:

-

Native wheat and commercial barley flours mixed at 60:40, wt:wt

- WT− CB+:

-

Blend of native wheat flour and commercial barley flour treated at 15% moisture for 1 h at 120 °C, mixed at 60:40, wt:wt

References

Cavallero A, Empilli S, Brighenti F, Stanca AM (2002) High-β-glucan barley fractions in bread making and their effects on human glycemic response. J Cereal Sci 36:59–66

Newman CW, El-Negoumy AM, Eslick RF (1978) Replacing soy protein in swine diets with high-protein barley and amino acids. J Anim Sci 46:161–166

Collar C, Angioloni A (2014) Nutritional and functional performance of barley flours in breadmaking: mixed breads vs wheat breads. Eur Food Res Technol 238:459–469

Gunaratne A, Hoover R (2002) Effect of heat-moisture on the structure and physicochemical properties of tuber and root starches. Carbohyd Polym 49:425–437

Collar C (2017) Significance of heat moisture treatment conditions on the pasting and gelling behaviour of various starch-rich cereal and pseudocereal flours. Food Sci Technol Int (accepted for publication May 2017)

Mann J, Schiedt B, Baumann A, Conde-Petit B, Vilgis TA (2013) Effect of heat treatment on wheat dough rheology and wheat protein solubility. Food Sci Technol Int 20(5):341–351

Zavareze ER, Dias ARG (2011) Impact of heat-moisture treatment and annealing in starches: a review. Carbohyd Polym 83:317–328

Seguchi M (1984) Oil-binding ability of heat-treated wheat starch. Cereal Chem 61:248–250

McCann TH, Leder A, Buckow R, Day L (2013) Modification of structure and mixing properties of wheat flour through high-pressure processing. Food Res Int 53(1):352–361

Chen X, He X, Fu X, Huang Q (2015) In vitro digestion and physicochemical properties of wheat starch/flour modified by heat-moisture treatment. J Cereal Sci 63:109–115

Bucsella B, Takács A, Vizer V, Schwendener U, Tömösközi S (2016) Comparison of the effects of different heat treatment processes on rheological properties of cake and bread wheat flours. Food Chem 190(2016):990–996

ICC (2014) ICC standard methods of the international association for cereal science and technology 104/1, 105/2, 110/1, 115/1, 136, 162, 166. The Association, Vienna

AOAC (1991) Total, soluble, and insoluble dietary fiber in foods. In: Association of Official Analytical Chemists

AOAC (2000) Official methods of analysis, 17th edn. AOAC International, Gaithersburg

FAO/WHO (2003) Food energy-methods of analysis and conversion factors. In: FAO Food and Nutrition Paper 77, Rome

AACC (2005) Approved methods of the American Association of Cereal Chemists, 10th edn. AACC St. Paul, MN: The Association

Traynham TL, Myers DJ, Carriquiry AL, Johnson LA (2007) Evaluation of water-holding capacity for wheat-soy flour blends. J Am Oil Chem Soc 84:151–155

Kaur M, Singh N (2005) Studies on functional, thermal and pasting properties of flours from different chickpea (Cicer arietinum L.) cultivars. Food Chem 91:403–411

Singh J, Singh N, Sharma TR, Saxena SK (2003) Physicochemical, rheological and cookie making properties of corn and potato flours. Food Chem 83:387–393

Angioloni A, Collar C (2009) Bread crumb quality assessment: a plural physical approach. Eur Food Res Technol 229:21–30

Collar C (2003) Significance of viscosity profile of pasted and gelled formulated wheat doughs on bread staling. Eur Food Res Technol 216:505–513

Armero E, Collar C (1997) Texture properties of formulated wheat doughs. Relationships with dough and bread technological quality. Zeitschrift für Lebensmittel-Untersuchung und Forschung A 204:136–145

Sozer N, Dalgic AC (2007) Modelling of rheological characteristics of various spaghetti types. Eur Food Res Technol 225:183–190

Yildiz O, Yurt B, Baştürk A, Toker OS, Yilmaz MT, Karaman S, Dağlıoğlu O (2013) Pasting properties, texture profile and stress–relaxation behavior of wheat starch/dietary fiber systems. Food Res Int 53(2013):278–290

Peleg M (1979) Characterisation of the stress relaxation curves of solid food. J Food Sci 44:277–281

Peleg M, Pollak NT (1982) The problem of equilibrium conditions in stress relaxation curves of solids foods. J Texture Stud 13:1–11

Zhang G, Hamaker BR (2005) Sorghum (Sorghum bicolor L. Moench) flour pasting properties influenced by free fatty acids and protein. Cereal Chem 82:534–540

Yadav DN, Kaur J, Anand T, Singh AK (2012) Storage stability and pasting properties of hydrothermally treated pearl millet flour. Int J Food Sci Technol 47:2532–2537

Hrazdina G (1971) Reaction of anthocyanin 3,5 glucosides, formation of 3,5-di(O-b-d-glucosyl)-7-hydroxy coumarin. Phytochemistry 10:1125–1130

Akingbala JO (1991) Effect of processing on flavonoids in millet (Pennisetum americum) flour. Cereal Chem 68:180–183

Bolade MK, Usman MA, Rasheed AA, Benson EL, Salifou I (2002) Influence of hydrothermal treatment of maize grains on the quality and acceptability of tuwon masara (traditional maize gel). Food Chem 79:479–483

Case SE, Hamann DD, Schwartz SJ (1992) Effect of starch gelatinization on physical properties of extruded wheat- and corn-based products. Cereal Chem 69:401–404

Waduge RN, Hoover R, Vasanthan T, Gao J, Li J (2006) Effect of annealing on the structure and physicochemical properties of barley starches of varying amylose content. Food Res Int 39:59–77

Jyothi AN, Sajeev MS, Sreekumar JN (2010) Hydrothermal modifications of tropical tuber starches. 1. Effect of heat-moisture treatment on the physicochemical, rheological and gelatinization characteristics. Starch/Stärke 62:28–40

Olayinka OO, Adebowale KO, Olu-Owolabi BI (2008) Effect of heat moisture treatment on physicochemical properties of white sorghum starch. Food Hydrocoll 22:225–230

Lawal OS (2005) Studies on the hydrothermal modifications of new cocoyam (Xanthosoma sagittifolium) starch. Int J Biol Macromol 37:268–277

Heywood AA, Myers DJ, Bailey TB, Johnson LA (2002) Functional properties of low-fat soy flour produced by an extrusion expelling system. J Am Oil Chem Soc 79:1249–1253

Ozawa M, Kato Y, Seguchi M (2009) Investigation of dry-heated hard and soft wheat flour. Starch/Stärke 61(7):398–406

Waterschoot J, Gomand SV, Fierens E, Delcour JA (2015) Starch blends and their physicochemical properties. Starch/Stärke 67:1–13

Collar C (2016) Impact of visco-metric profile of composite dough matrices on starch digestibility and firming and retrogradation kinetics of breads thereof: additive and interactive effects of non-wheat flours. J Cereal Sci 69:32–39

Collar C, Balestra F, Ancarani D (2014) Value added of resistant starch maize based matrices in breadmaking: nutritional and functional assessment. Food Bioprocess Technol 7:3579–3590

Liu H, Corke H, Ramsden L (2000) The effect of autoclaving on the acetylation of ae, wx and normal maize starches. Starch 52:353–360

Sun Q, Wang T, Xiong L, Zhao Y (2013) The effect of heat moisture treatment on physicochemical properties of early indica rice. Food Chem 141:853–857

Mohsenin NN (1986) Physical properties of plant and animal materials. Structure, physical characteristics and mechanical properties, 2nd edn. Gordon and Breach Science Publisher Inc, New York

Gamero M, Fiszman SM, Duran L (1993) Stress relaxation of fruit gels. Evaluation of models and effects of concentration. J Food Sci 58(1125–1128):1134

Acknowledgements

The authors acknowledge the institutions Ministerio de Economía y Competitividad (MINECO) and Federación Europea de Desarrollo Regional (FEDER) for funding the Project AGL2015-63849-C2-1-R.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Compliance with ethics requirements

This article does not contain any studies with human or animal subjects.

Rights and permissions

About this article

Cite this article

Collar, C., Armero, E. Impact of heat moisture treatment and hydration level on physico-chemical and viscoelastic properties of doughs from wheat-barley composite flours. Eur Food Res Technol 244, 355–366 (2018). https://doi.org/10.1007/s00217-017-2961-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-017-2961-8