Abstract

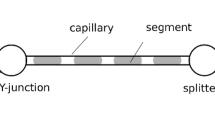

Here, we present the effect of rapeseed microstructure on the extraction mechanism. “Solution and diffusion” extraction had to be considered to deepen the understanding of the process. Transmitted light microscopy images of the ultramicrotome-cut casting sections proved the presence of “conductive” capillary system with radius R from 8 to 25 μm. The rate of “solution extraction” was controlled by capillary flow through “conductive” voids. It was described by derived and extended Hagen–Poiseuille equation. The rate of solvent extraction of soybeans was described by negative power function, whereas rapeseed extraction was defined by complex nonlinear curve-fitting model. Specific surface area of large (1.3 ± 0.1 m2 g−1) and small (1.5 ± 0.1 m2 g−1) fraction of rapeseed extraction meal particles did not differ significantly, contrary to flaked soybeans. This is the novel finding. Significant differences could be explained by vegetable seed histology context (seed and cell size, sorption abilities). “Diffusion extraction” was rate determining at the flat part of the time-dependent extraction curve. Isolated fraction of free fatty acids originated from simultaneous lipolysis of acylglycerol species and hydrolysis of glycerophospholipids and glyceroglycolipids. Decreasing quality of last fractions increased refining loss and material costs. Compounds such as waxes (6.89–10.40 wt%), complex glycerolipids (14.83–15.26 wt%), and free fatty acids (2.26–2.45 wt%) had to be removed by edible oil refining.

Similar content being viewed by others

References

Bockisch M (1998) Fats and oils handbook. AOCS Press, Champaign, pp 360–439

Bernardini E (1976) Batch and continuous solvent extraction. J Am Oil Chem Soc 53:275–278

Stein W, Glaser FW (1976) Continuous solvent extraction of sunflower seed, groundnuts, palmkernels, rapeseed, and copra. J Am Oil Chem Soc 53:283–285

Karnofsky G (1949) The theory of solvent extraction. J Am Oil Chem Soc 26:564–569

Diosady LL, Rubin LJ, Ting N, Trass O (1983) Rapid extraction of canola oil. J Am Oil Chem Soc 60:1658–1661

Ayers AL, Scott CR (1951) Cottonseed oil extraction with normal hexane and methylpentanes. J Am Oil Chem Soc 28:348–351

Şaşmaz DA (1996) Evaluation of the diffusion coefficient of rapeseed oil during solvent extraction with hexane. J Am Oil Chem Soc 73:669–672

Stanley DW, Gill TA, deMan JM, Tung MA (1976) Microstructure of rapeseed. Can Inst Food Sci Technol J 9:54–60

Cornell D, Katz DL (1951) Flow rates through soybean flakes. Ind Eng Chem 43:992–996

Wingard MR, Shand WC (1949) The determination of the rate of extraction of crude lipids from oil seeds with solvents. J Am Oil Chem Soc 26:422–426

Coats HB, Wingard MR (1950) Solvent extraction. III. The effect of particle size on extraction rate. J Am Oil Chem Soc 27:93–96

Wingard MR, Phillips RC (1951) Solvent extraction. IV. The effect of temperature on extraction rate. J Am Oil Chem Soc 28:149–152

Becker W (1978) Solvent extraction of soybeans. J Am Oil Chem Soc 55:754–761

Arnold LK, Choudhury RBR (1961) The fatty acid composition of cottonseed oil at various stages of solvent extraction. J Am Oil Chem Soc 38:87–88

Baumler ER, Crapiste GH, Carelli AA (2010) Solvent extraction: kinetic study of major and minor compounds. J Am Oil Chem Soc 87:1489–1495

Jolivet P, Deruyffelaere C, Boulard C, Quinsac A, Savoire R, Nesi N, Chardot T (2013) Deciphering the structural organization of the oil bodies in the Brassica napus seed as a mean to improve the oil extraction yield. Ind Crops Prod 6:549–557

Katavic V, Agrawal GK, Hajduch M, Harris SL, Thelen JJ (2006) Protein and lipid composition of oil bodies from two Brassica napus cultivars. Proteomics 6:4586–4598

Schneider FH (1980) Zur extraktiven Lipid-Freisetzung aus pflanzlichen Zellen. Fette Seifen Anstrichmittel 82:16–22

Schneider FH, Rütte U (1989) Flüssigkeitsbindung in Ölsaaten I: bindungsrelevante Strukturelemente. Lipid/Fett 91:337–346

Schneider FH, Rütte U (1990) Flüssigkeitsbindung in Ölsaaten II: Bindungs-Mechanismen. Lipid/Fett 92:347–354

Schneider FH, Rütte U (1991) Resthexan in Raps-Schroten I: Zur Entstehung einer intrazellularen Miszella. Lipid/Fett 93:319–327

Oilseeds—Determination of moisture and volatile matter content. ISO 665, 2000

Oilseeds—Determination of oil content. ISO 659, 2000

Extrahované šroty olejnatých semen—Stanovení obsahu oleje—Část 2: Rychlá extrakční metoda. ČSN EN ISO 734-2, 2009

Wewer V, Dombrink I, vom Dorp K, Dörmann P (2011) Quantification of sterol lipids in plants by quadrupole time-of-flight mass spectrometry. J Lipid Res 52:1039–1041

Kaluzny MA, Duncan LA, Merritt MV, Epps DE (1985) Rapid separation of lipid classes in high yield and purity using bonded phase columns. J Lipid Res 26:135–140

Christie WW, Han X (2010) Lipid analysis—isolation, separation, identification and lipidomic analysis, 4th edn. The Oily Press, Bridgwater, pp 69–74

Preparation of methyl esters of fatty acids. ISO 5509, 2000

del Valle MJ, Germain JC, Uquiche E, Zetzl C, Brunner G (2006) Microstructural effects on internal mass transfer of lipids in prepressed and flaked vegetable substrates. J Supercrit Fluids 37:178–190

Fernández MB, Perez EE, Crapiste GH, Nolasco SM (2012) Kinetic study of canola oil and tocopherol extraction: parameter comparison of nonlinear models. J Food Eng 111:682–689

Determination of the content of trans fatty acid isomers of vegetable fats and oils—gas chromatographic method. ISO 15304, 2002

Bartovská L, Šišková M (2010) Fyzikální chemie povrchů a koloidních soustav, 6th edn. VŠCHT, Praha, pp 19–37

Atkins P, de Paula J (2013) Atkinś physical chemistry (9th Czech edition). VŠCHT, Praha, pp 705–732

Rice P, Hamm W (1988) Densities of soybean oil/solvent mixtures. J Am Oil Chem Soc 65:1177–1179

Othmer DF, Agarwal JC (1955) Extraction of soybeans, theory and mechanism. Ind Eng Chem 51:372–378

Othmer DF, Jaatinen W (1959) Extraction of soybeans, mechanism with various solvents. Ind Eng Chem 51:543–546

Sochi T (2013) Newtonian flow in converging-diverging capillaries. Int J Model Simul Sci Comput 4:1350011

Fan HP, Morris JC (1948) Diffusion phenomena in solvent extraction of peanut oil—effect of cellular structure. Ind Eng Chem 40:195–199

Chorny RC, Krasuk JH (1966) Extraction for different geometries—constant diffusivity. Ind Eng Chem Process Des Dev 5:206–208

Hu X, Daun JK, Scarth R (1994) Proportions of C18:1n-7 and C18:1n-9 fatty acids in canola surface and internal lipids. J Am Oil Chem Soc 71:221–222

Acknowledgments

This work was supported by funding from the Hlávkova foundation and financial support from specific university research (MSMT No 20/2014). The authors are indebted to associate professor Jan Vidensky for measuring porosity and specific surface area values.

Conflict of interest

None.

Compliance with Ethics requirements

This article does not contain any studies with human or animal subjects.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kyselka, J., Kreps, F., Matlova, V. et al. The effect of rapeseed microstructure on the mechanism of solution and diffusion extraction. Eur Food Res Technol 240, 853–863 (2015). https://doi.org/10.1007/s00217-014-2392-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-014-2392-8