Abstract

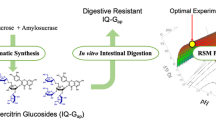

Response surface methodology (RSM) was employed to optimize amyloglucosidase-catalyzed synthesis of curcumin-bis-α-d-glucoside. A central composite rotatable design (CCRD) was employed involving five variables (enzyme concentration, curcumin concentration, incubation period, buffer concentration and pH) at five levels. A second-order polynomial equation with a R 2 value 0.9 showed good correspondence between experimental and predicted yields. Three-dimensional surface and contour plots generated described the catalytic efficiency of amyloglucosidase under the reaction conditions employed. A maximum conversion of 35% was predicted for curcumin concentrations above 0.55 mmol at 35–60% (w/w d-glucose) amyloglucosidase concentrations. While lower (<35%) amyloglucosidase concentrations converted less, concentrations >60% could be inhibitory to curcumin. Extent of glucosylation was governed by a critical buffer (0.95–1.0 ml of 0.01 M pH 6.0) to enzyme ratio (15–45% w/w d-glucose). Experiments under optimum predicted conditions of 16.9% (w/w d-glucose) amyloglucosidase, 0.33 mmol curcumin, 120 h incubation period, 0.1 mM (1.0 ml of 0.01 M) buffer concentration at pH 7.5 gave a conversion yield of 56.3%. Validation experiments carried out under selected random conditions also showed good correspondence between experimental and predicted yields.

Similar content being viewed by others

References

Busch P, Hensen H, Kahre J, Tesmann H (1994) Agro-Food-Industry Hi-Technol 9:23–28

Hsu FL, Lee YY, Cheng JT (1994) J Nat Prod 57:308–312

Carlton RR, Deans SG, Gray AI, Waterman PG (1991) Chemoecology 2:69–71

Kahne DE, Walker KS (1993) PCT Int. Appl. WO 9311772A1

Konstantinovic S, Predojevic J, Gojkovic S, Ratkovic Z, Mojsilovic B, Pavlovic V (2001) Indian J Chem 40B:1242–1244

Noshita T, Sugiyama T, Kitazumi Y, Oritani T (1995) Biosci Biotechnol Biochem 59:2052–2055

Oku M, Sakai Y (2003) Saibo Kogaku 22:992–993 (Japanese)

Sophie L, Robert G, Pierre K (2004) Chem Commun 5:586–587

Du Y, Wei G, Linhardt RJ (2004) J Org Chem 69:2206–2209

Hergenhahn M, Bertram B, Wiessler M, Sorg BL (2002) German patent application. DE 2337

Aritomi M, Komori T, Kawasaki T (1986) Phytochemistry 25:231–234

Mohri K, Watanable Y, Yoshida Y, Satoh M, Isobe K, Sugimoto N, Tsuda Y (2003) Chem Pharm Bull 51:1268–1272

Vic G, Thomas D, Crout DHG (1997) Enzyme Microb Technol 20:597–603

Lirdprapamongkol K, Svasti J (2000) Biotechnol Lett 22:1889–1894

Yoon SH, Bruce Fulton D, Robyt JF (2004) Carbohydr Res 339:1517–1529

Washino K (1992) Jpn. Kokkyo koho JP 04066098 A2. 1992

Huang KH, Akoh CC (1996) J Food Sci 61:137–141

Shieh CJ, Akok CC, Koehler PE (1995) J Am Oil Chem Soc 72:619–623

Ibanoglu E, Ibanoglu S (2000) Food Chem 70:333–336

Yan Y, Bornscheuer UT, Stadler G, Wahl SL, Reuss R, Schmid RD (2001) J Am Oil Chem Soc 78:147–152

Ismail A, Soultani S, Ghoul M (1998) Biotechnol Prog 14:874–878

Ismail A, Linder M, Ghoul M (1999) Enzyme Microbial Technol 25:208–213

Chahid Z, Montet D, Pina M, Bonnot F, Graille J (1994) Biotechnol Lett 16:795–800

Vijayakumar GR, Manohar B, Divakar S (2005) Eur Food Res Technol 220:272–277

Gomes DCF, Alegrio LV, Leon LL, de Lima MEF (2002) Arzneim-Forsch 52:695–698

Vijayakumar GR, Divakar S (2005) Biotechnol Lett 27:1411–1415

Montogomery DC (1991) Design and analysis of experiments. Wiley, New York, pp 542–547

Chahid Z, Montet D, Pina M, Graille J (1992) Biotechnol Lett 14:281–284

Frandsen TP, Dupont C, Lehmbeck J, Stoffer B, Sierks MR, Honzatko RB, Svensson B (1994) Biochemistry 33:13808–13816

Sierks MR, Ford C, Reilly PJ, Svensson B (1990) Protein Eng 3:193–198

Acknowledgements

Department of Science and Technology, India is gratefully acknowledged for the financial support. GRV acknowledges Council of Scientific and Industrial Research (CSIR), New Delhi, India for providing the Senior Research Fellowship.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Vijayakumar, G.R., Manohar, B. & Divakar, S. Amyloglucosidase-catalysed synthesis of curcumin-bis-α-d-glucoside—a response surface methodological study. Eur Food Res Technol 223, 725–730 (2006). https://doi.org/10.1007/s00217-006-0259-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-006-0259-3