Abstract

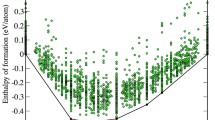

Al–Si binary system forms eutectic alloys with about 12% Si and their mechanical and physical properties are strongly related to the distribution of eutectic silicon in the microstructure. This paper studies the structures of Al32-nSin (n = 2, 4, 6, 8) crystals by using global evolutionary algorithm combined with density functional theories. The lowest energy structures are determined and the bonding strengths of the Al–Al, Al–Si and Si–Si bonds are evaluated. The binding energies of the alloy crystals increase considerably with the silicon content and the dispersion of silicon atoms is favorable for the stability. At given composition, the dispersion of Si atoms forms two Al–Si bonds at the expense of one Al–Al and one Si–Si bonds and the energy gain is 0.022 eV. The mechanical properties are investigated and the calculated moduli show that the shear modulus and Young’s modulus are related obviously to the silicon composition and distributions while the bulk moduli are quite close for all of the alloy structures. The moduli values are largest for Al28Si4 (its silicon content is close to the eutectic) and its Young’s modulus is 31% larger than the pure aluminum.

Similar content being viewed by others

References

Tiwary CS, Pandey P, Sarkar S et al (2022) Five decades of research on the development of eutectic as engineering materials[J]. Prog Mater Sci 123:100793

Ashkenazi D (2019) How aluminum changed the world: a metallurgical revolution through technological and cultural perspectives[J]. Technol Forecast Soc 143:101–113

Aamir M, Giasin K, Tolouei-Rad M et al (2020) A review: drilling performance and hole quality of aluminium alloys for aerospace applications[J]. J Mater Res Technol 9(6):12484–12500

Zhang X, Chen Y, Hu J (2018) Recent advances in the development of aerospace materials[J]. Prog Aerosp Sci 97:22–34

Miller WS, Zhuang L, Bottema J et al (2000) Recent development in aluminium alloys for the automotive industry[J]. Mat Sci Eng A 280:37–49

Yang H, Gao T, Zhang H et al (2019) Enhanced age-hardening behavior in Al–Cu alloys induced by in-situ synthesized TiC nanoparticles[J]. J Mater Sci Technol 35:374–382

Yang B, Wang Y, Gao M et al (2021) The response of mechanical property to the microstructure variation of an Al–Mg alloy by adding tin element[J]. Mat Sci Eng A 825:141901

Huter P, Renhart P, Oberfrank S et al (2016) High- and low-cycle fatigue influence of silicon, copper, strontium and iron on hypo-eutectic Al–Si–Cu and Al–Si–Mg cast alloys used in cylinder heads[J]. Int J Fatigue 82:588–601

Totten GE, Tiryakioğlu M, Kessler O (2018) Encyclopedia of aluminum and its alloys[M]. CRC Press, 2018.

Wu Y, Liao H, Tang Y (2021) Enhanced high-cycle fatigue strength of Al–12Si–4Cu-1.2Mn-T6 cast aluminum alloy at room temperature and 350 C[J]. Mat Sci Eng A 825:141917

Li J, Ye Z, Fu J et al (2020) Microstructure evolution, texture and laser surface HEACs of Al-Mg-Si alloy for light automobile parts[J]. Mater Charact 160:110093

Li C, Xu J, Xu J et al (2016) Rounded silicon edges on the surface of Al–Si alloy cylinder liner by means of mechanical grinding treatment[J]. Tribol Int 104:204–211

Su J, Nie X, Stoilov V (2010) Characterization of fracture and debonding of Si particles in AlSi alloys[J]. Mat Sci Eng A 527:7168–7175

Ye H (2003) An overview of the development of Al-Si-alloy based material for engine applications[J]. J Mater Eng Perform 12:288–297

Summer F, Pusterhofer M, Grün F et al (2020) Tribological investigations with near eutectic AlSi alloys found in engine vane pumps–Characterization of the material tribo-functionalities[J]. Tribol Int 146:106236

Makhlouf MM, Guthy HV (2001) The aluminum–silicon eutectic reaction: mechanisms and crystallography[J]. J light metals 1:199–218

Murray JL, McAlister AJ (1984) The Al-Si (aluminum-silicon) system[J]. Bull Alloy Phase Diagrams 5(1):74

Hegde S, Prabhu KN (2008) Modification of eutectic silicon in Al–Si alloys[J]. J Mater Sci 43:3009–3027

Hosch T, Napolitano RE (2010) The effect of the flake to fiber transition in silicon morphology on the tensile properties of Al–Si eutectic alloys[J]. Mat Sci Eng A 528:226–232

Akyüz B (2016) Effect of silicon content on machinability of A–Si alloys[J]. Adv Sci Technol Res J 10:51–57

Jeon JH, Shin JH, Bae DH (2019) Si phase modification on the elevated temperature mechanical properties of Al–Si hypereutectic alloys[J]. Mat Sci Eng A 748:367–370

Nikanorov SP, Volkov MP, Gurin VN et al (2005) Structural and mechanical properties of Al–Si alloys obtained by fast cooling of a levitated melt[J]. Mat Sci Eng A 390:63–69

Xu CL, Jiang QC (2006) Morphologies of primary silicon in hypereutectic Al–Si alloys with melt overheating temperature and cooling rate[J]. Mat Sci Eng A 437:451–455

Wang S, Fu M, Li X et al (2018) Microstructure and mechanical properties of Al–Si eutectic alloy modified with Al–3P master alloy[J]. J Mater Process Tech 255:105–109

Zhang L, Chen S, Li Q et al (2020) Formation mechanism and conditions of fine primary silicon being uniformly distributed on single αAl matrix in Al–Si alloys[J]. Mater Design 193:108853

Barrirero J, Li J, Engstler M et al (2016) Cluster formation at the Si/liquid interface in Sr and Na modified Al–Si alloys[J]. Scripta Mater 117:16–19

Haghayeghi R, Timelli G (2021) An investigation on primary Si refinement by Sr and Sb additions in a hypereutectic Al–Si alloy[J]. Mater Lett 283:128779

Lee Y, Jung J, Kim S et al (2021) Effect of thermo-mechanical treatment and strontium addition on workability and mechanical properties of AlSiCu casting alloy[J]. Mater Charact 178:111256

Srirangam P, Kramer MJ, Shankar S (2011) Effect of strontium on liquid structure of Al–Si hypoeutectic alloys using high-energy X-ray diffraction[J]. Acta Mater 59:503–513

Liao H, Sun Y, Sun G (2002) Correlation between mechanical properties and amount of dendritic α-Al phase in as-cast near-eutectic Al–11.6% Si alloys modified with strontium[J]. Mat Sci Eng A 335:62–66

Qin J, Pan S, Qi Y et al (2016) The structure and thermodynamic properties of liquid Al–Si alloys by ab initio molecular dynamics simulation[J]. J Non-Cryst Solids 433:31–37

Huang X, Dong X, Liu L et al (2019) Liquid structure of Al-Si alloy: a molecular dynamics simulation[J]. J Non-Cryst Solids 503–504:182–185

Chen B, Zhang C, Jin Y (2020) First-principles calculation of interface binding strength and fracture performance of β’/Al interface in Al–Mg–Si–Cu alloy[J]. J Alloy Compd 830:154515

Lu Y, Zhang S, Wang Y et al (2022) Mechanical properties of Bʹ precipitates and fracture behavior of Bʹ/Al interface in Al–Mg–Si alloys: a first-principle calculation study[J]. Appl Surf Sci 571:151329

Liang J, Liu Z, Rao K et al (2021) First-principles calculation for displacive phase transition of atomic-scale precipitates in aluminum alloys. Phys Lett A 411:127569

Wang Y, Lu Y, Zhang S et al (2021) Analysis of interface properties and associated void of nanoscale Al precipitates in Al–Si alloys: first-principles calculations and experiment[J]. J Alloy Compd 873:159598

Oganov AR, Glass CW (2006) Crystal structure prediction using ab initio evolutionary techniques: principles and applications[J]. J Chem Phys 124:244704

Glass CW, Oganov AR, Hansen N (2006) USPEX—Evolutionary crystal structure prediction[J]. Comput Phys Commun 175:713–720

Lyakhov AO, Oganov AR, Stokes HT et al (2013) New developments in evolutionary structure prediction algorithm USPEX[J]. Comput Phys Commun 184:1172–1182

Kresse G, Furthmüller J (1996) Efficiency of ab-initio total energy calculations for metals and semiconductors using a plane-wave basis set[J]. Comp Mater Sci 6:15–50

Perdew JP, Burke K, Ernzerhof M (1996) Generalized gradient approximation made simple[J]. Phys Rev Lett 77:3865

Gaudoin R, Foulkes WMC, Rajagopal G (2002) Ab initio calculations of the cohesive energy and the bulk modulus of aluminium[J]. J Phys: Condens Matter 14:8787–8793

Mouhat F, Coudert FX (2014) Necessary and sufficient elastic stability conditions in various crystal systems[J]. Phys Rev B 90:224104

Hill R (1952) The elastic behaviour of a crystalline aggregate[J]. Proc Phys Soc A 65:349

Acknowledgements

This work is supported by the National Natural Science Foundation of China (NSFC, Grant No. 1216040199). We also thank National Supercomputer Centre in Shenzhen for computational resource.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Zhang, L., Chen, H. Aggregation or dispersion of Si atoms in Al–Si alloys? from the view point of energetics. Theor Chem Acc 141, 14 (2022). https://doi.org/10.1007/s00214-022-02873-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00214-022-02873-x