Abstract

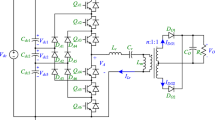

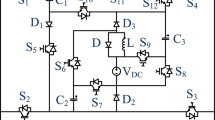

A dual output direct AC–AC series resonant converter is presented in this paper, to meet the requirements of modern domestic induction heating. To address the significant limitations of the classic induction heating system, a hybrid control approach comprising pulse frequency modulation and asymmetrical duty-cycle control is developed. A single source is connected to multiple loads with this control technique to achieve minimum switching losses; power controllability of two loads is achieved independently and simultaneously. The power controllability of two loads is achieved independently and simultaneously. This research presents an induction heating system that can heat both ferromagnetic and non-ferromagnetic materials, such as steel and aluminum. A prototype is developed to use switching frequencies of 30 kHz and 150 kHz for steel load and aluminum load, respectively. The experimental setup resulted in an efficiency of 97.5% under wide load resonant condition. The suggested hybrid control approach allows the converter to regulate a wide range of output power while increasing efficiency, making it suitable for practical induction heating.

Similar content being viewed by others

References

Kumaraswamy A, Bhattacharya A, Sadhu PK (2021) A multilevel boost converter-fed high-frequency resonant inverter for induction heating by using ADC control. Lecture Notes in Electrical Engineering, vol 707. Springer, Singapore. https://doi.org/10.1007/978-981-15-8586-9_5

Miladi Y, Feki M, Derbel N (2016) Optimal control of a single-phase H-bridge DC–AC inverter. Int. J. Circuit Theor. Appl. 44:744–758. https://doi.org/10.1002/cta.2104

Papani SK, Neti V, Murthy BK (2015) Dual frequency inverter configuration for multiple-load induction cooking application. IET Power Electron 8(4):591–601

Bhattacharya A, Sadhu PK, Bhattacharya A, Pal N (2016) Voltage-controlled hybrid resonant inverter—an essential tool for induction heated equipment. Rev Roum Des Sci Tech Ser Electrotech Energy 61(3):273–277

Mishima T, Nakagawa Y, Nakaoka M (2015) A bridgeless BHB ZVS-PWM AC–AC converter for high-frequency induction heating applications. IEEE Trans Ind Appl 51(4):3304–3315. https://doi.org/10.1109/TIA.2015.2409177

Komeda S, Fujita H (2018) A phase-shift-controlled direct AC-to-AC converter for induction heaters. IEEE Trans Power Electron 33(5):4115–4124. https://doi.org/10.1109/TPEL.2017.2712281

Mishima T, Sakamoto S, Ide C (2017) ZVS phase-shift PWM-controlled single-stage boost full-bridge AC–AC converter for high-frequency induction heating applications. IEEE Trans Ind Electron 64(3):2054–2061. https://doi.org/10.1109/TIE.2016.2620098

Han W, Chau KT, Zhang Z, Jiang C (2017) Single-source multiple-load homogeneous induction heating. IEEE Trans Mag 53(11):1–6. https://doi.org/10.1109/TMAG.2017.2717867

Kumar PS (2017) Multiple-load series resonant inverter for induction cooking application with pulse density modulation. Sadhana Acad Proc Eng Sci 42(8):1309–1316. https://doi.org/10.1007/s12046-017-0651-7

Gomes RCM, Vitorino MA, Acevedo-Bueno DA, Correa MBDR (2020) Multiphase resonant inverter with coupled loads for AC–AC induction heating application. IEEE Trans Ind Appl 56(1):551–560. https://doi.org/10.1109/TIA.2019.2955661

Sarnago H, Lucía O, Burdio JM (2019) Multiresonant power converter for improved dual-frequency induction heating. IEEE Trans Power Electron 34(3):2097–2103. https://doi.org/10.1109/TPEL.2018.2839965

Han W, Jiang CC, Liu W (2018) All-metal domestic induction heating using single-frequency double-layer coils. IEEE Trans Mag 54(11):1–5. https://doi.org/10.1109/TMAG.2018.2846548

Park H, Jung J (2018) Load-adaptive modulation of a series-resonant inverter for all-metal induction heating applications. IEEE Trans Ind Electron 65(9):6983–6993. https://doi.org/10.1109/TIE.2018.2793270

Han W, Chau KT, Liu W, Tian X, Wang H (2022) A dual-resonant topology-reconfigurable inverter for all-metal induction heating. IEEE J Emerg Select Top Power Electron. https://doi.org/10.1109/JESTPE.2021.3071700

Khatroth S, Shunmugam P (2021) Single-stage pulse frequency controlled AC–AC resonant converter for different material vessel induction cooking applications. Int J Circuit Theor Appl 49:1–20

Burdio JM, Barragan LA, Monterde F, Navarro D, Acero J (2004) Asymmetrical voltage-cancellation control for full-bridge series resonant inverters. IEEE Trans Power Electron 19(2):461–469. https://doi.org/10.1109/TPEL.2003.823250.N

Vishnuram P, Ramachandran G (2021) A simple multi-frequency multiload independent power control using pulse density modulation scheme for cooking applications. Int Trans Electr Energy Syst 31:e12771

Han W, Chau K, Lam W (2019) All-utensil domestic induction heating system. Energy Convers Manag 195:1035–1043. https://doi.org/10.1016/j.enconman.2019.05.093

Ramalingam SR, Boopthi CS, Ramasamy S, Ahsan M, Haider J (2021) Induction heating for variably sized ferrous and non-ferrous materials through load modulation. Energies 14:8354. https://doi.org/10.3390/en14248354

Vijaya Bhaskar D, Vishwanathan N, Maity T, Porpandiselvi S (2017) Hybrid controlled dual-frequency inverter for two load induction cooking application. EPE J 27(2):60–73. https://doi.org/10.1080/09398368

Prado EO, Bolsi PC, Sartori HC, Pinheiro JR (2022) Simple analytical model for accurate switching loss calculation in power MOSFETs using non-linearities of Miller capacitance. IET Power Electron 15:594–604. https://doi.org/10.1049/pel2.12252

Koller L, Novák B (2017) Improving the energy efficiency of induction cooking 2. Electr Eng 99:171–178. https://doi.org/10.1007/s00202-016-0405-2

Aunsborg TS, Duun SB, Munk-Nielsen S, Uhrenfeldt C (2022) Development of a current source resonant inverter for high current MHz induction heating. IET Power Electron 15:1–10. https://doi.org/10.1049/pel2.12204

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kumaraswamy, A., Bhattacharya, A. & Sadhu, P.K. Dual output direct AC–AC series resonant converter for all metal induction heating system with a hybrid control technique. Electr Eng 105, 1363–1375 (2023). https://doi.org/10.1007/s00202-023-01743-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00202-023-01743-4