Abstract

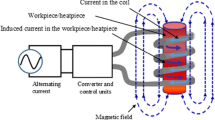

In the October 2009 issue of this Journal, we introduced a special pot type, which could improve the energy efficiency of induction cooking, make the boiling process faster and the cooking more comfortable. The dissipated power in the new pot was significantly higher than in the traditional ones at any inductor current. In this paper we show another pot type with similar advantages, but having a simpler structure. The main model parameters were the same as in our previous work: we used the same material properties, including the B–H curve of the ferromagnetic pot material, the same arrangement of the coil-pot system, and the same formula for calculating the hysteresis loss. We applied similar inductor current with \(f = 25~\hbox {kHz}\) frequency in the finite element analyses, but instead of 2D, we had to use 3D models because of the pot structure. The non-linear magnetization curve necessitated the use of transient simulations, and we calculated the steady-state rms results from the exact time variations of the field quantities.

Similar content being viewed by others

References

Koller L, Novák B (2009) Improving the energy efficiency of induction cooking. Electr Eng 91:153–160. doi:10.1007/s00202-009-0127-9

Koller L (1992) New impulse operating medium frequency thyristor controlled inverter for induction heating. In: Proceedings of the 10th international symposium on electromachining. Magdeburg Technical University, Germany, pp 726–736

Koller L, Gy Tevan, Kiss I (2002) Investigation of induction heating of non-ferromagnetic metal half-space with corrugated surface: the exciting magnetic field is parallel to the enveloping line of the corrugated profile. Period Polytech Ser El Eng 46:3–14

Koller L, Gy Tevan, Kiss I (2002) Investigation of induction heating of non-ferromagnetic metal half-space with corrugated surface: the exciting magnetic field is perpendicular to the plane of the corrugated profile. Period Polytech Ser El Eng 46:15–28

Koller L (2001) Tégelyes olvasztókemencék induktor-betét rendszerei hatásfokának vizsgálata 2D végeselem számítással: mérések. (Investigation of the efficiency of crucible type induction furnaces by 2D finite element calculations: measurements). Study of OTKA research project T2445, Budapest, Hungary, pp 1–39

Koller L (2003) Neuartiger Tiegel für Induktionsöfen mit gerippter Wandfläche (New type of crucible with ribbed surface for induction furnaces). Elektrowärme Int 61(2):75–79

Koller L, Gy Tevan, Kiss I (2004) Optimisation of electrical parameters of induction melting furnaces with graphite crucible. Elektrowärme Int 62(3):122–125

Koller L, Tevan Gy, I Kiss I (2002) Crucible for the induction melting of metals and/or maintaining the temperature of molten metals. Patent PCT/HU02/00002, Hungarian Patent Office

Gy Tevan (2010) Analytical skin effect models in electrical engineering. Akadémiai Kiadó, Budapest

Koller L, Novák B (2009) Ridged surface for reducing eddy-current losses in ferromagnetic shielding. Electr Eng 91:117–124. doi:10.1007/s00202-009-0124-z

ANSYS Inc. (2005) Theory reference, Ansys Release 10.0, ANSYS Inc

Demerdash NA, Gillott DH (1974) A new approach for determination of eddy currents and flux penetration in nonlinear ferromagnetic materials. IEEE Trans Magn 10:682–685

Mur G (1994) Edge elements, their advantages and their disadvantages. IEEE Trans Magn 30:3552–3557

Wang JS, Ida N (1993) Curvilinear and higher order, edge’ finite elements in electromagnetic field computation. IEEE Trans Magn 29:1491–1494

Liska J (1958) Villamos Gépek 1. Transzformátorok (Electrical machines 1. Transformers). Tankönyvkiadó, Budapest

Directive 2004/40/EC of the European Parliament and of the Council of 29 April 2004 on the minimum health and safety requirements regarding the exposure of workers to the risks arising from physical agents (electromagnetic fields) (18th individual Directive within the meaning of Article 16 (1) of Directive 89/391/EEC) European Parliament; Council of the European Union

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Koller, L., Novák, B. Improving the energy efficiency of induction cooking 2. Electr Eng 99, 171–178 (2017). https://doi.org/10.1007/s00202-016-0405-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00202-016-0405-2