Abstract

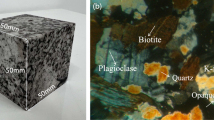

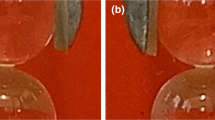

PTFE/Al/W granular composite is a kind of impact-initiated energetic material and may well enhance damage to the impacted targets. To gain insight into response behavior of PTFE/Al/W granular composite under different loadings, the combined approach of experiments and theoretical analyses is used in this paper. More specifically, the combinations of quasi-static compression, dynamic tests, and ballistic impact experiments are conducted. Cylindrical PTFE/Al/W granular composite specimens, with a density of 7.7 \(\hbox {g/cm}^{3}\) and a diameter of 10 mm, are fabricated by cold press molding, sintering, and cooling. Moreover, a high-speed imaging technique is used to record response process of the specimens in ballistic impact experiments. The experimental and analytical results show that the response behavior of PTFE/Al/W granular composite is significantly influenced by the loading strain rate. When the strain rate is less than \(3.6\times 10^{3}\,\hbox {s}^{-1}\), only mechanical response is observed in the quasi-static compression and dynamic tests. However, when the strain rate is higher than \(4\times 10^{4}\,\hbox {s}^{-1}\), the chemical reaction is found in the ballistic impact experiments. Furthermore, chemical response shows an enhanced trend with increasing of the loading strain rate.

Similar content being viewed by others

Data availability

All data generated or analyzed during this study are available from the corresponding author on reasonable request.

References

Wang, H.F., Liu, Z.W., Yu, W.M.: Impact initiated characteristics of reactive material fragments. Proceedings of 7th International Fall Seminar on Propellants, Explosives and Pyrotechnics, pp. 123–128. National Natural Science Foundation of China, Xi’an (2007) (in Chinese)

Geng, B.Q., Wang, H.F., Yu, Q.B., Zheng, Y.F., Ge, C.: Bulk density homogenization and impact initiation characteristics of porous PTFE/Al/W reactive materials. Materials 13, 2271 (2020). https://doi.org/10.3390/ma13102271

Zheng, Y.F.: Research on enhanced lethality effects and mechanisms of reactive materials. PhD Thesis, Beijing Institute of Technology, China (2012) (in Chinese)

Zhang, F.: Some issues for blast from a structural reactive material solid. Shock Waves 28, 693–707 (2018). https://doi.org/10.1007/s00193-018-0815-3

Vine, T., Stubberfield, J., Jobson, D., Kirkpatrick, D., McLean, S.: Penetration and ignition performance of reactive fragments. 29th International Symposium on Ballistics, Edinburgh, Scotland, pp. 1847–1853 (2016)

Ames, R.G.: Energy release characteristics of impact-initiated energetic materials. MRS Online Proc. Lib. 896, 308 (2005). https://doi.org/10.1557/PROC-0896-H03-08

Raftenberg, M.N., Mock, W., Kirby, G.C.: Modeling the impact deformation of rods of a pressed PTFE/Al composite mixture. Int. J. Impact Eng. 35(12), 1735–1744 (2008). https://doi.org/10.1016/j.ijimpeng.2008.07.041

Mock, W., Drotar, J.T.: Effect of aluminum particle size on the impact initiation of pressed PTFE/Al composite rods. AIP Conf. Proc. 955, 971–974 (2007). https://doi.org/10.1063/1.2833292

Sorensen, B.: High-velocity impact of encased Al/PTFE projectiles on structural aluminum armor. The 13th hypervelocity impact symposium. Proc. Eng. 103, 569–576 (2015). https://doi.org/10.1016/j.proeng.2015.04.074

Herbold, E.B., Nesterenko, V.F., Benson, D.J., Cai, J., Vecchio, K.S., Jiang, F., Addiss, J.W., Walley, S.M., Proud, W.G.: Particle size effect on strength, failure, and shock behavior in polytetrafluoroethylene-Al–W granular composite materials. J. Appl. Phys. 104, 103903 (2008). https://doi.org/10.1063/1.3000631

Herbold, E.B.: Optimization of the dynamic behavior of strongly nonlinear heterogeneous materials. PhD Thesis, University of California, San Diego (2008). http://escholarship.org/uc/item/03f6q1m0

Cai, J., Walley, S.M., Hunt, R.J.A., Proud, W.G., Nesterenko, V.F., Meyers, M.A.: High-strain, high-strain-rate flow and failure in PTFE/Al/W granular composites. Mater. Sci. Eng. A 472(1–2), 308–315 (2008). https://doi.org/10.1016/j.msea.2007.03.068

Cai, J.: Properties of heterogeneous energetic materials under high strain, high strain rate deformation. PhD Thesis, University of California, San Diego, USA (2007). http://escholarship.org/uc/item/71166051

Zhang, X.F., Zhang, J., Qiao, L., Shi, A.S., Zhang, Y.G., He, Y., Guan, Z.W.: Experimental study of the compression properties of Al/W/PTFE granular composites under elevated strain rates. Mater. Sci. Eng. A 581, 48–55 (2013). https://doi.org/10.1016/j.msea.2013.05.063

Qiao, L., Zhang, X.F., He, Y., Shi, A.S., Guan, Z.W.: Mesoscale simulation on the shock compression behavior of Al–W-Binder granular metal mixtures. Mater. Des. 47, 341–349 (2013). https://doi.org/10.1016/j.matdes.2012.12.013

Wang, L., Liu, J.X., Li, S.K., Zhang, X.B.: Investigation on reaction energy, mechanical behavior and impact insensitivity of W-PTFE-Al composites with different W percentage. Mater. Des. 92, 397–404 (2016). https://doi.org/10.1016/j.matdes.2015.12.045

Lee, R.J., Mock, W., Jr., Carney, J.R., Holt, W.H., Pangilinan, G.I., Gamache, R.M., Boteler, J.M., Bohl, D.G., Drotar, J., Lawrence, G.W.: Reactive materials studies. AIP Conf. Proc. 845, 169–174 (2006). https://doi.org/10.1063/1.2263291

Wang, L.L.: Foundation of Stress Waves. National Defense Industry Press, London (2005) (in Chinese)

Xu, F.Y., Yu, Q.B., Zheng, Y.F., Lei, M.A., Wang, H.F.: Damage effects of double-spaced aluminum plates by reactive material projectile impact. Int. J. Impact Eng. 104, 13–20 (2017). https://doi.org/10.1016/j.ijimpeng.2017.01.023

Yossifon, G., Yarin, A.L.: Behind-the-armor debris analysis. Int. J. Impact Eng. 27(8), 807–835 (2002). https://doi.org/10.1016/S0734-743X(02)00009-X

Acknowledgements

The work described in this paper was supported by the National Natural Science Foundation of China (Grant No. 11902087), the Start-up Funds for High-level Personnel Research of Guizhou Institute of Technology (No. XJGC20190957), the Engineering Research Centers of Guizhou Ordinary Institution of Higher Education under Grant ([2018]007), and the Creative Research Groups Program of Guizhou Educational Commission under Grant ([2018]026).

Author information

Authors and Affiliations

Corresponding author

Additional information

Communicated by P. Hazell.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Xu, F.Y., Wang, H.F., Kang, J. et al. Response behavior of the PTFE/Al/W granular composite under different loadings. Shock Waves 32, 633–642 (2022). https://doi.org/10.1007/s00193-022-01101-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00193-022-01101-6