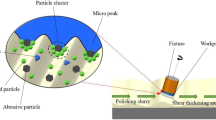

The parameters for chemical–mechanical polishing (CMP) in an ultra-large scale integrated (ULSI) planarisation process are explored. First, an analysis of variance (ANOVA) is conducted on the CMP process parameters derived from the Taguchi method. The objective is to understand the ranking of the effects of CMP parameters such as down force pressure, platen speed, carrier speed, oscillation, and flowrate on the removal rate. Findings are verified by grey relational analysis. The values of the sequencing results allow us to adjust the parameters to the required machining condition during the CMP experiment. This will reduce the number of experiments needed and the length of time required. This study also analyses the effect of data normalisation and data integrity in grey relational analysis on the degree of sensitivity. The results indicate that it is feasible to use grey relational analysis to predict the rank of the parameter effect in the case of insufficient data derived from the Taguchi method.

Similar content being viewed by others

Author information

Authors and Affiliations

Additional information

ID="A1"Correspondance and offprint requests to: Professor Z.-C. Lin, Department of Mechanical Engineering, National Taiwan University of Science and Technology, 43 Keelung Road, Section 4, Taipei 10672, Taiwan. E-mail: zclin@mail.ntust.edu.tw

Rights and permissions

About this article

Cite this article

Ho, CY., Lin, ZC. Analysis and Application of Grey Relation and ANOVA in Chemical–Mechanical Polishing Process Parameters. Int J Adv Manuf Technol 21, 10–14 (2003). https://doi.org/10.1007/s001700300001

Issue Date:

DOI: https://doi.org/10.1007/s001700300001