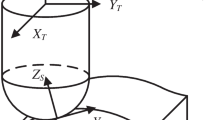

The paper presents a geometric modelling approach for the precision design and NC machining of a concave-arc ball-end milling (CABEM) cutter which is an important tool for mould-making industries. This paper presents systematic models of the cutting edge, helical groove, and grinding wheel design for the NC machining of a CABEM cutter. Both the normal to the revolving axis and the tangent to the groove, are used to derive the required precision sectional profiles of the grinding wheel. In compliance with the maximal sectional radius of the cutter, the profile of the groove section and both the radial and axial cutting speeds of the grinding wheel are computed in sequence. Using the computer simulation results of the groove actually obtained, this paper proposes a method to resolve the problems of the residual revolving surface and the narrow cutting edge strip. This paper is intended to serve as a reference for the design and NC machining of cutters of this type

.

Similar content being viewed by others

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Chen, WF., Chen, CK. & Lai, HY. Design and NC Machining of Concave-Arc Ball-End Milling Cutters. Int J Adv Manuf Technol 20, 169–179 (2002). https://doi.org/10.1007/s001700200140

Issue Date:

DOI: https://doi.org/10.1007/s001700200140