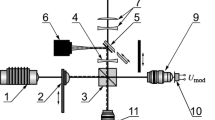

An in-process surface monitoring system for laser cleaning processes has been developed based on a chromatic modulation technique. The chromatic monitoring system consists of tristimulus photodetectors, fibre optics and a PC-based data acquisition and processing system. This monitor produces measurements that are dependent on the spectral signature of reflected light on the surface but are independent of the light intensity. In order to demonstrate its usefulness and versatility, the system was used for surface monitoring in the laser cleaning of paper and stone. Results show that the spectral parameters derived from chromatic detection provide not only a clear indication of the surface cleanliness and surface damage but also much surface chromatic information from its unique characteristics. It is also shown how a chromatic modulation technique can be used as a fast and reliable method for monitoring the surface during laser cleaning.

Similar content being viewed by others

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Lee, J., Steen, W. In-Process Surface Monitoring for Laser Cleaning Processes using a Chromatic Modulation Technique. AMT 17, 281–287 (2001). https://doi.org/10.1007/s001700170181

Issue Date:

DOI: https://doi.org/10.1007/s001700170181