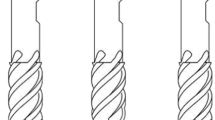

The paper presents a mathematical model for producing a ball-end cutter by first defining the helical angle as the angle between the cutting edge and the centre-line axis. The velocities of the cutter in the radial and axial directions are then derived based on a given rotating speed. The radial feed speed of the grinding wheel is calculated according to the groove cross-section passing through the centre of the ball-end cutter. A ball-end cutter of constant helical angle is designed and produced by using a two-axis NC machine. To enhance the dimensional accuracy of the mathematical model, a compensatory grinding operation is also proposed and applied to the ball-end cutter. A ball-end milling cutter is selected for design and manufacture to illustrate the effectiveness of the proposed design and numerically controlled (NC) manufacturing procedure. The result of data verification indicates that the proposed procedure is systematic, straightforward and reliable. The ball-end cutter that is designed, refined and produced by using a simple two-axis NC machine is accurate enough to meet the specified tolerance.

Similar content being viewed by others

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Lin, SW., Lai, HY. A Mathematical Model for Manufacturing Ball-End Cutters Using a Two-Axis NC Machine. AMT 17, 881–888 (2001). https://doi.org/10.1007/s001700170099

Issue Date:

DOI: https://doi.org/10.1007/s001700170099