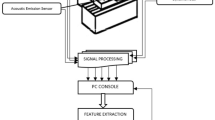

The sensor fusion method using both an acoustic emission (AE) sensor and a built-in force sensor is introduced for on-line tool condition monitoring during turning. The cutting force was measured by a built-in piezoelectric force sensor, which was inserted in the tool turret housing of an NC lathe. FEM analysis was carried out to locate the most sensitive position for the sensor. A burst of AE signal was used as a triggering signal to inspect the cutting force. A significant drop in cutting force indicated tool breakage. The algorithm was implemented in a DSP board and the monitoring system was installed on a CNC lathe in an FMS line for in-process tool-breakage detection. The proposed system showed an excellent monitoring capability.

Similar content being viewed by others

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Choi, D., Kwon, W. & Chu, C. Real‐Time Monitoring of Tool Fracture in Turning Using Sensor Fusion. Int J Adv Manuf Technol 15, 305–310 (1999). https://doi.org/10.1007/s001700050071

Issue Date:

DOI: https://doi.org/10.1007/s001700050071